For BMW enthusiasts looking to enhance the performance of their OBD2-equipped cars, an OBD1 conversion is a popular modification. While often described as a simple swap, it’s a detailed process that requires careful planning and execution. This guide, based on real-world experience, will walk you through the intricacies of converting your OBD2 BMW engine management system to OBD1, focusing on achieving optimal performance and understanding the key differences between these systems.

Before diving in, let’s understand why some BMW owners opt for an OBD1 conversion. OBD1, the earlier On-Board Diagnostics system, is favored in the BMW community primarily for its simpler engine management and perceived performance advantages, particularly when combined with aftermarket tuning solutions. The M50 intake manifold, typically associated with OBD1 systems, is known for its superior airflow compared to the OBD2 manifolds found on engines like the M52 and S52. This conversion, therefore, is not just about diagnostics; it’s about unlocking potential performance gains.

Here’s a look at an OBD2 S52 engine before the conversion process begins:

OBD2 S52 Engine Before Conversion

OBD2 S52 Engine Before Conversion

Alt text: A detailed view of an OBD2 S52 BMW engine bay before undergoing an OBD1 conversion, showcasing the original engine management system components.

This guide is tailored for owners of OBD2 BMWs, like the 1999 M3 mentioned in the original post, aiming to switch to an OBD1 setup. It utilizes components like an OBD1 engine harness from a 1994 325i and a red-label 413 ECU, commonly used in these conversions. Let’s break down the parts you’ll need and the steps involved in making this significant upgrade.

Essential Parts for Your OBD1 Conversion

To successfully convert your OBD2 BMW to OBD1 management, you’ll need a specific set of components. Sourcing these parts is the first crucial step in your project. Here’s a comprehensive list:

- OBD1 Engine Harness: This is the backbone of the conversion, providing the necessary connections for the OBD1 ECU and sensors.

- OBD1 ECU (413 “Red Label” Preferred): The “red label” 413 ECU is highly sought after because it originates from non-EWS (anti-theft system) cars, simplifying the installation.

- OBD1 Chip: An aftermarket performance chip, like the Active Autowerkes chip mentioned, is often used to optimize engine performance with the OBD1 system.

- OBD1 Intake Manifold: The M50 intake manifold is key for performance gains due to its improved airflow.

- OBD1 Fuel Rail: Necessary to accommodate the OBD1 fuel system setup and fuel pressure regulator.

- OBD1 Crank Position Sensor: Different in location and type compared to OBD2, this sensor is essential for OBD1 engine timing.

- OBD1 Cam Position Sensor: Similar to the crank sensor, the OBD1 cam position sensor is required for the OBD1 system.

- OBD1 Knock Sensors (x2): OBD1 systems use different knock sensors, and you’ll need a pair for proper engine protection.

- OBD1 Oxygen Sensor: OBD1 systems typically use a single pre-catalyst oxygen sensor, unlike the multiple sensors in OBD2 systems.

- OBD1 HFM (Hot-Film Air Mass Meter): The OBD1 air mass meter is calibrated for the OBD1 ECU and intake system.

- OBD1 Main Engine Coolant Hose: Due to differences in the cooling system routing between OBD1 and OBD2, this hose is required.

- OBD1 Throttle Boot: Connects the OBD1 HFM to the throttle body and is designed for the OBD1 system.

- OBD1 Throttle Body (Optional): While the OBD2 throttle body can be adapted, using an OBD1 throttle body can simplify the installation.

- OBD1 Valve Cover and Coil Packs (Optional): Depending on your preference for coil pack mounting and wiring, OBD1 valve cover and coil packs might be beneficial.

Step-by-Step OBD1 Conversion Process

The OBD1 conversion is not just a simple parts swap; it requires meticulous attention to detail and a solid understanding of your BMW’s engine systems. Here’s a breakdown of the key steps, addressing the nuances of each component.

1. Valve Cover and Coil Packs: OBD1 vs OBD2 Configurations

One of the first decisions you’ll face is regarding the valve cover and coil packs. OBD2 valve covers route coil pack connectors from the passenger side, while OBD1 systems route them from the driver’s side.

Here’s a comparison:

OBD2 Coil Pack Setup

OBD2 Coil Pack Setup

Alt text: Image illustrating the OBD2 coil pack setup on a BMW engine, showing the wiring and connector routing specific to OBD2 systems.

OBD1 Coil Pack Setup

OBD1 Coil Pack Setup

Alt text: Image displaying the OBD1 coil pack configuration on a BMW engine, highlighting the differences in wiring and connector placement compared to OBD2 systems.

You have a couple of options:

- Keep OBD2 Valve Cover: This allows you to retain your OBD2 coil packs. You’ll need to slightly modify the valve cover, typically with a Dremel tool, to accommodate the OBD1 harness wiring routing.

- Switch to OBD1 Valve Cover: This requires using OBD1 coil packs. Both OBD1 and OBD2 coil versions are compatible with the OBD1 harness, so the choice is based on your preference for aesthetics and ease of wiring.

2. Vanos Solenoid Wiring: Adapting the Connection

The Vanos (Variable Valve Timing) solenoid connector differs between OBD1 and OBD2. The OBD2 connector wire is shorter. To address this, you can either:

- Use an OBD1 Vanos Solenoid: Swap your OBD2 solenoid for an OBD1 version.

- Extend OBD2 Wiring: Keep your OBD2 solenoid and extend its wiring. A recommended solution is using BMW part # 12-52-2-274-971, a transmission harness with compatible connectors, ideal for extending the Vanos solenoid wiring.

Here’s a look at the harness:

Vanos Solenoid Harness Extension

Vanos Solenoid Harness Extension

Alt text: Image of a BMW transmission harness (part # 12-52-2-274-971) used to extend the OBD2 Vanos solenoid wiring for OBD1 conversion, showcasing the connector compatibility.

3. Coolant Pipe Modification: Adapting to OBD1 Hose

The main coolant pipe from the timing cover is another point of divergence. OBD2 uses a fixed metal pipe, while OBD1 uses a rubber hose connected to an aluminum neck. You have choices here as well:

- OBD1 Timing Cover: Replace your OBD2 timing cover with an OBD1 version. This is a more involved solution as it requires timing cover removal.

- Coolant Pipe Adapter: A more straightforward approach is to use a coolant pipe adapter. These adapters, available from BMW parts specialists like Bimmerworld, Active Autowerkes, or Turner Motorsport, fit into the OBD2 timing case cover and allow you to connect the OBD1 coolant hose using a pipe clamp. JB Weld is typically used to secure the adapter.

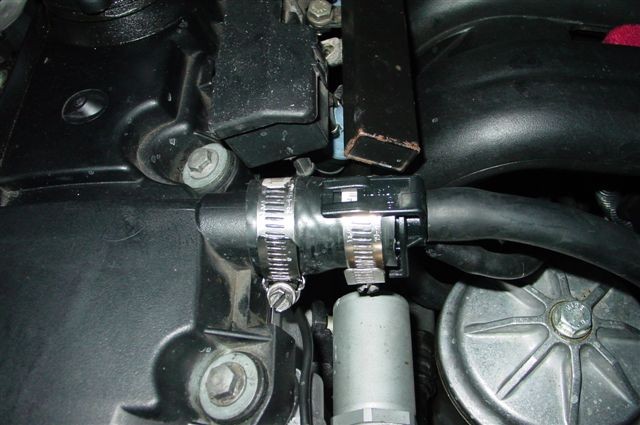

Here’s an example of the coolant pipe adapter in place:

Coolant Pipe Adapter Location

Coolant Pipe Adapter Location

Alt text: Image showing the coolant pipe adapter (aluminum pipe below the oil filter housing) installed on an OBD2 engine for OBD1 conversion, enabling the use of an OBD1 coolant hose.

4. Intake Manifold Swap: Unleashing Performance

The OBD1 intake manifold, specifically the M50 manifold, is a key component for performance gains in this conversion. It offers improved airflow compared to OBD2 manifolds (M52/S52). This swap is essential for realizing the performance benefits of the OBD1 conversion. The M50 manifold is a direct bolt-on to M52/S52 cylinder heads. It includes an air temperature sensor and a vacuum port for the fuel pressure regulator on the underside.

5. Throttle Body Compatibility: Adapters and Options

You can retain your OBD2 throttle body, but it requires adaptation due to different gasket sealing surfaces between OBD1 and OBD2 intake manifolds.

- Adapter Plate: Use a throttle body adapter plate. This plate fits between the OBD2 throttle body and OBD1 manifold, providing compatible mating surfaces for both gasket types.

- Extended Gasket: An extended gasket can also bridge the gap and allow direct mounting of the OBD2 throttle body to the OBD1 intake manifold.

- OBD1 Throttle Body: For simplicity, you can switch to an OBD1 throttle body, eliminating the need for adapters or special gaskets.

6. Coolant Temperature Sender: Adapting to OBD1 Configuration

OBD2 systems use a single coolant temperature sender, while OBD1 uses two. OBD1 senders are located on the cylinder head.

- Splicing and OBD2 Sender: You can splice the OBD1 harness wiring and use the OBD2 plug connector to connect to your single OBD2 temp sender.

- Wiring Adapter: A cleaner solution is to use a coolant temperature sender wiring adapter, available from Turner Motorsport. This adapter is plug-and-play and simplifies the wiring process.

7. Crank Position Sensor: Switching Sensor Types

The crank position sensor location and type differ between OBD1 and OBD2. OBD2 sensors are on the engine block, while OBD1 sensors are located on the timing cover. You must use an OBD1 crank position sensor for this conversion. Leave the OBD2 sensor in place to plug the hole in the block.

8. Fuel Line Modifications: Reconfiguring the Fuel System

Significant changes are needed to the fuel lines. OBD2 fuel rails have fuel lines attaching at the rear, and the fuel pressure regulator is under the car near the fuel filter. OBD1 fuel rails have the supply line at the front and the return line at the back, with the fuel pressure regulator on the fuel rail itself.

You must use the OBD1 fuel rail, which necessitates modifying the fuel lines. Remove the OBD2 fuel pressure regulator from under the car. Run new 8mm fuel lines to the OBD1 fuel rail. Bridge the gap left by the removed OBD2 fuel pressure regulator using new fuel line, connecting the feed from the fuel filter to the front of the OBD1 fuel rail, and the return line from the back of the OBD1 fuel rail to the return line under the car. Connect the OBD1 fuel pressure regulator vacuum line to the one-way valve on the OBD1 intake manifold.

9. PCV System Adaptation: Handling Crankcase Ventilation

The Positive Crankcase Ventilation (PCV) system differs between OBD1 and OBD2. Options to address this include:

- OBD2 Valve Cover with OBD2 PCV: If retaining the OBD2 valve cover, keep the OBD2 PCV setup. You’ll need to mount the breather valve (cone-shaped plastic valve) under the intake manifold.

- OBD1 Valve Cover with OBD1 Breather Valve: If using an OBD1 valve cover, use the OBD1 breather valve that clips onto the crankcase vent port. Connect the OBD1 valve vacuum line to the ICV-to-intake manifold plug and the oil drain line to the dipstick.

- Breather Catch Can: Alternatively, use a hose from the crankcase vent to a breather catch can.

Here’s an example of a PCV setup:

Custom PCV Setup

Custom PCV Setup

Alt text: Image illustrating a custom PCV setup for an OBD1 converted BMW, showing the connection of the OBD2 valve cover to an OBD1 breather valve using a rubber hose.

10. Idle Control Valve (ICV) and Fuel Tank Breather: Minor Adjustments

The OBD1 and OBD2 ICVs are the same and interchangeable. Reuse your OBD2 ICV. You’ll need the correct connector and hoses for the ICV to intake manifold and throttle boot connections. Similarly, the OBD2 fuel tank breather valve can be reused. You’ll need fittings to connect the vacuum hose to the throttle boot vacuum port.

11. Oxygen Sensors and Secondary Air Pump: Emission System Changes

OBD1 systems eliminate the secondary air pump and post-catalyst oxygen sensors found in OBD2 systems. Remove the secondary air pump entirely. You’ll also eliminate the two pre-cat and two post-cat OBD2 O2 sensors. Plug the O2 sensor ports in the exhaust system – M18 bolts are suitable for this. OBD1 management uses only one pre-catalyst oxygen sensor.

12. Oil Pan and Dipstick: No Changes Needed

Contrary to some misconceptions, the OBD2 oil pan and dipstick can be used without modification in an OBD1 conversion.

13. EWS (Immobilizer) Considerations: Addressing Security Systems

EWS presence varies across E36 models. Using a non-EWS ECU (like the “red label” 413) simplifies this. However, ignition issues might still arise. A simple modification to the main engine harness can bypass EWS: Cut wire #66 (typically solid green or black/violet) on the ECU connector. Insulate both cut ends with electrical tape.

14. Power Distribution and Grounding: Ensuring Electrical Integrity

Crucially, disconnect the negative battery post before working on any electrical connections. OBD2 power distribution is located on the passenger side near the ECU. The OBD2 distribution box will need to be relocated slightly to reach the OBD1 harness power connections. Removing the secondary air pump creates space to remount the distribution box closer to the firewall.

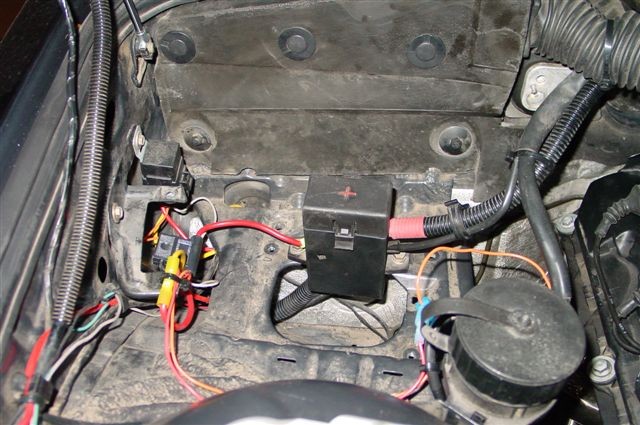

Here’s an example of relocated power terminals:

Relocated Power Terminal

Relocated Power Terminal

Alt text: Image showing a relocated power terminal box in a BMW OBD1 conversion, adjusted to fit the OBD1 harness connections after removing the secondary air pump system.

Ensure correct power and ground connections. Power feeds are typically RED, and grounds are BROWN or BLACK. Double-check wiring if unsure. There are main power feeds to the starter and fuse box, and a ground wire from the spark plug rail that grounds to the engine hoist loop on the Vanos unit.

15. General Wiring: Labeling is Key

Label all connectors before disconnecting and installing the new harness. Use Bentley wiring schematics as a guide. Label each connector with painter’s tape and a marker. Take pictures of OBD2 wiring, especially power and ground connections, and starter wiring.

Here’s a harness with labeled connectors:

Labeled OBD1 Harness

Labeled OBD1 Harness

Alt text: Image of an OBD1 engine harness with all connectors meticulously labeled for easy identification and installation during a BMW OBD1 conversion project.

Dyno Results and Performance Gains

After completing the OBD1 conversion, dyno testing is crucial to assess performance improvements. The example car, a 1999 M3 OBD1 S52 with modifications like AA Cam Chip, Sunbelt Cams, and Euro HFM, initially dynoed at 253 RWHP and 228 TQ. After tuning adjustments, particularly leaning out the rich fuel mixture, the final dyno results improved to 262 RWHP and 230 TQ. These numbers indicate a notable performance increase from the OBD1 conversion and associated modifications.

Conclusion: Is OBD1 Conversion Right for You?

Converting your OBD2 BMW to OBD1 is a complex but rewarding project for those seeking enhanced engine performance and simpler engine management. It’s not a straightforward “electronics swap” but a detailed modification requiring careful component selection, precise wiring, and adjustments to various engine systems. While this guide provides a comprehensive overview, professional consultation and thorough research are highly recommended before undertaking such a conversion. The performance gains, particularly when combined with other modifications and tuning, can make the OBD1 conversion a worthwhile upgrade for dedicated BMW enthusiasts.