The Ford Bronco, a classic SUV, evolved significantly over its production years, especially in its engine management and diagnostic systems. For enthusiasts and owners of the 1990s Broncos, understanding the On-Board Diagnostics (OBD) systems is crucial for maintenance and upgrades. This article delves into the specifics of OBD systems in 1990s Ford Broncos, with a focus on the transition to OBD2 and what it means for your vehicle, particularly if you’re dealing with a 1996 model.

OBD-I vs. OBD-II: The Diagnostic Evolution

In the early 1990s, vehicles like the Ford Bronco utilized OBD-I, specifically Ford’s Electronic Engine Control version Four (EEC-IV). This system, while a step forward from earlier diagnostics, had limitations in terms of standardization and the depth of data it could provide. The year 1996 marked a significant shift in automotive diagnostics with the widespread adoption of OBD-II. This new standard, also known as EEC-V in Ford terminology, brought about substantial changes in engine management computers, sensor systems, and diagnostic capabilities.

For 1996 Ford Broncos, this meant a move to the more advanced OBD-II system. While earlier 90s Broncos (1992-1995) used EEC-IV and OBD-I, the 1996 model embraced the new standard. This transition is vital for anyone working on or diagnosing a 1996 Bronco, as it affects everything from reading diagnostic codes to understanding engine performance.

Key Differences in 1996 Bronco OBD2 System

The shift to OBD-II in the 1996 Bronco brought about several specific changes compared to the OBD-I systems in earlier models. These differences are not just about the diagnostic connector but extend to the engine management system itself.

Engine Management Computer

The most fundamental change was the engine management computer. The 1996 Bronco switched from the EEC-IV (OBD-I) to the EEC-V (OBD-II) computer. This new computer was more powerful and capable of monitoring a wider range of engine parameters with greater precision, as required by the OBD-II standard.

Heated Oxygen Sensors

Emissions control was a significant driver for the OBD-II transition. The 1996 Bronco with Federal emissions standards came equipped with three heated exhaust gas oxygen sensors. California emissions models went even further, incorporating an additional sensor. These heated sensors are more efficient at reaching operating temperature quickly, providing faster and more accurate feedback to the engine management system, especially during cold starts.

Crankshaft Position Sensor and Misfire Detection

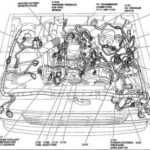

A crucial addition in the 1996 Bronco was the Crankshaft Position Sensor, also known as a misfire detection sensor. This sensor, coupled with a tone ring on the crankshaft, monitors the crankshaft’s rotation for irregularities that could indicate engine misfires.

Alt text: Location of the misfire sensor near the timing pointer in a 1996 Ford Bronco 5.8L engine, highlighting OBD2 misfire detection capabilities.

The Powertrain Control Module (PCM) uses the signals from this sensor to detect misfires. If a certain number of misfires occur within a specific timeframe, the PCM will illuminate the Check Engine Light (CEL) to alert the driver to a potential issue. This misfire detection is a key feature of OBD-II, enhancing the ability to diagnose engine problems and emissions issues.

Fuel Injection Systems: Speed Density vs. Mass Air Flow

Earlier EEC-IV Broncos often used Speed Density (SD) Electronic Fuel Injection (EFI) systems. SD EFI relies on sensors like the Manifold Absolute Pressure (MAP) sensor, Throttle Position Sensor (TPS), and Air Intake Temperature (ACT) sensor to estimate the amount of air entering the engine. It uses pre-programmed volumetric efficiencies to calculate fuel delivery. SD EFI systems typically use bank fire injection, where injectors on each engine bank fire simultaneously.

In contrast, the 1996 Bronco, like many OBD-II vehicles, utilized Mass Air Flow (MAF) or Sequential Electronic Fuel Injection (SEFI). MAF systems directly measure the mass of air entering the engine, providing more accurate data for fuel calculations. SEFI systems, in turn, fire each injector individually, allowing for more precise fuel delivery and improved engine efficiency and emissions. While the text mentions 1994 5.0L and most 95 5.8L as SD, and 95 5.0L, 95 5.8L California models and all 96s as MAF, it’s essential to verify the specific configuration for your Bronco based on the engine and emissions specifications.

Air Injection System Differences

The Secondary Air Injection system, often called the smog pump system, also saw changes. Interestingly, while the 1996 Bronco 5.0L engine included the Air Injection (AIR) system components like the pump, Thermactor Air Bypass (TAB) & Thermactor Air Diverter (TAD) solenoids, diverter, check & bypass valves, and cross-over tube, the 1996 Bronco 5.8L engine surprisingly did not include this system. This is a specific difference to note when working on these engines.

Differential Pressure Feedback (DPFE) Sensor

Another emission-related change in 1996 Broncos is the use of a Differential Pressure Feedback (DPFE) Sensor instead of an EGR Valve Position (EVP) Sensor. This change started in 95 5.8L California models and became standard in all 1996 models. The DPFE sensor provides more accurate feedback on the Exhaust Gas Recirculation (EGR) flow, which is critical for emissions control.

Vapor Management Valve (VMV)

The evaporative emissions system also evolved with OBD-II. In 1996, the Vapor Management Valve (VMV) replaced the canister purge valve (CanP valve) used in EEC-IV systems. Although some 1996 manuals might still refer to the CanP valve due to the late production change, the VMV is the component you’ll find in 1996 Broncos. It’s typically located on the passenger side firewall, where the MAP sensor was positioned in earlier years.

Alt text: Location of the Vapor Management Valve (VMV) on the passenger side firewall of a 1996 Ford Bronco, showcasing an OBD2 emissions control component.

The fuel-rated hose from the VMV connects to the throttle body, similar to how the CanP valve was connected in previous models.

Alt text: Location of the Differential Pressure Feedback (DPFE) sensor in a 1996 Ford Bronco 5.0L engine, highlighting its role in OBD2 emissions monitoring.

The DPFE sensor is often found on the driver’s side, near the throttle body, and faces forward.

Firing Order and Spark Plug Wire Routing

While not directly OBD-II related, it’s important to note the changes in firing order and spark plug wire routing for 1990s Broncos, especially when working on engine maintenance.

Alt text: Firing order diagrams for Ford 5.0L and 5.8L engines, illustrating the differences between pre-1994 and 1994-1996 models relevant to 1990 Bronco engine maintenance.

For 1987-1993 5.0L engines, the firing order is 1-5-4-2-6-3-7-8. However, for 1994-96 5.0L engines and all 5.8L engines, the firing order is 1-3-7-2-6-5-4-8. Understanding the correct firing order is crucial for proper engine operation and diagnostics.

Alt text: Diagram of spark plug wire routing for Ford engines, emphasizing correct wiring for optimal engine performance in 1990s Broncos.

Alt text: Diagram showing the location of the Engine Coolant Temperature (ECT) sensor and Intake Air Temperature (IAT) sensor in Ford engines of the 1990s, relevant for OBD2 system understanding.

Sensors and Components: Minor Variations

While many sensors like the Engine Coolant Temperature (ECT) Sensor and Temperature Gauge Sender remained the same, there were subtle changes in others. The Intake Air Temperature (IAT) sensor (referred to as Air Charge Temperature [ACT] prior to 1992) was relocated. After mid-1994, for 5.0L/5.8L engines, the ACT/IAT sensor moved from the lower intake manifold to the air filter box. This relocation is often accompanied by a name change from ACT to IAT, reflecting its new location and function in measuring intake air temperature.

In general, Speed Density Broncos typically have the ACT sensor on the lower intake manifold, while Mass Air Flow Broncos have the IAT sensor in the air box. These sensors are fundamentally the same but may have different PCM programming values and wiring harness configurations depending on the EFI system.

Throttle Body and Related Components

There are also differences in components like the Idle Air Control (IAC) valve, Throttle Position Sensor (TPS), Throttle Body, Fuel Injection Pressure Regulator, and EGR Valve between earlier and later 1990s Broncos. For example, the IAC and TPS units have different part numbers for 1990 5.0L versus 1996 5.0L engines.

Throttle bodies in EFI engines up to 1992 could be cleaned, but later models, particularly from 1996 onwards, may have a sealant or coating on the throttle plate and bore that should not be removed during cleaning. Fuel Injection Pressure Regulators and EGR Valves also differ between earlier and later models, especially due to the shift to DPFE sensors in OBD-II systems.

Notably, 1996 5.0L & 5.8L Broncos do not require a knock sensor, according to Ford specifications.

Conclusion: Navigating 1990 Bronco OBD Systems

Understanding the nuances of OBD systems in 1990s Ford Broncos, especially the transition to OBD-2 in 1996, is crucial for accurate diagnostics and maintenance. While earlier models used OBD-I (EEC-IV) with Speed Density fuel injection and a simpler sensor setup, the 1996 Bronco adopted OBD-II (EEC-V), incorporating Mass Air Flow, enhanced emissions controls, and misfire detection.

When working on a 1990s Bronco, especially a 1996 model, it’s essential to identify the correct OBD system and engine management components. This knowledge ensures accurate troubleshooting, effective repairs, and helps keep these classic SUVs running reliably while meeting modern diagnostic standards. For owners and mechanics alike, recognizing these differences is key to properly servicing and maintaining these iconic vehicles.