Need to understand the Obd2 Pinout?

This comprehensive guide dives deep into the OBD2 (On-Board Diagnostics II) pinout, the standardized connector that provides access to your vehicle’s diagnostic data. We’ll explore the function of each pin in the OBD2 connector, its role in vehicle communication, and how understanding the obd2 pinout is crucial for automotive diagnostics and data access.

Whether you’re a seasoned mechanic, a car enthusiast, or just curious about your car’s inner workings, understanding the obd2 pinout is your first step towards unlocking a wealth of vehicle information.

You can also watch our OBD2 intro video above – or get the PDF

In this article

Author: Martin Falch (updated January 2025)

PDF icon

PDF icon

Download as PDF

Decoding the OBD2 Connector: What is OBD2?

OBD2 is essentially your car’s internal health monitor. It’s a standardized system that allows you to retrieve diagnostic trouble codes (DTCs) and real-time vehicle data through a universal interface: the OBD2 connector. This 16-pin connector is the gateway to your vehicle’s onboard computer systems, and understanding its obd2 pinout is key to effective vehicle diagnostics.

You’ve likely encountered OBD2 in action without even realizing it. Remember that check engine light on your dashboard? That’s OBD2 signaling a problem. When you take your car to a mechanic, they use an OBD2 scanner, which plugs into the OBD2 16 pin connector, typically located under the dashboard near the steering wheel. This tool sends requests via the obd2 pinout, and the car responds with data like speed, engine temperature, fuel levels, and those all-important Diagnostic Trouble Codes (DTCs). By understanding the obd2 pinout, mechanics can quickly and accurately diagnose issues, saving time and money.

Image showing a malfunction indicator light (MIL) and an OBD2 scan tool connected to a car, illustrating the basic use of OBD2 for diagnostics.

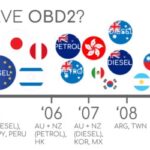

OBD2 Compatibility: Does Your Car Have an OBD2 Port?

The good news is, if you own a relatively modern car, the answer is almost certainly yes! OBD2 has become the industry standard for non-electric vehicles. While most modern cars have the 16-pin OBD2 connector, it’s important to know that simply having the connector doesn’t automatically mean it’s OBD2 compliant, especially for older vehicles. To confirm OBD2 compliance, consider the car’s origin and year of manufacture:

Does My Car Have OBD2?

Does My Car Have OBD2?

Infographic showing OBD2 compliance timelines for vehicles in the EU and US, helping users determine if their car is OBD2 compliant based on the region and year of purchase.

A Brief History of OBD2 and the OBD2 Pinout Standard

The story of OBD2 begins in California, driven by the California Air Resources Board (CARB)’s need for improved emission control. Starting in 1991, CARB mandated OBD in all new vehicles sold in California for emission monitoring.

The Society of Automotive Engineers (SAE) played a crucial role in standardizing OBD, leading to the OBD2 standard. A key part of this standardization was defining the obd2 pinout and Diagnostic Trouble Codes (DTCs) to ensure consistency across different car manufacturers. The SAE J1962 standard specifically outlines the physical obd2 pinout and connector.

The OBD2 standard was gradually adopted worldwide:

- 1996: OBD2 became mandatory in the USA for cars and light trucks.

- 2001: The EU mandated OBD2 for gasoline cars (EOBD).

- 2003: EOBD extended to diesel cars in the EU.

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US vehicles were required to use ISO 15765-4 (CAN) as the foundation for OBD2 communication, influencing the obd2 pinout usage for CAN.

- 2010: OBD2 became mandatory for heavy-duty vehicles in the US.

Diagram illustrating the history of OBD2 development and its connection to emission control and the evolution towards CAN bus integration.

Timeline graphic summarizing the key milestones in OBD2 history and its global adoption.

Visual representation of the future trends in OBD, including OBD3, remote diagnostics, and integration with cloud and IoT technologies.

The Future of OBD2 and Access to Vehicle Data

While OBD2 remains relevant, the automotive landscape is evolving. The rise of electric vehicles (EVs) presents a shift, as many current EVs don’t fully adhere to standard OBD2 protocols, particularly for emissions-related diagnostics. EVs often utilize OEM-specific UDS communication, making standard OBD2 tools less effective. However, reverse engineering efforts are making progress in accessing data from EVs like Tesla, Hyundai/Kia, Nissan, and VW/Skoda.

Modern OBD alternatives like WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) are emerging to address the limitations of traditional OBD2. These protocols aim to enhance OBD communication by building upon the UDS protocol, offering more streamlined and richer data access beyond the original OBD2 specifications and obd2 pinout functionalities.

The concept of OBD3 envisions incorporating telematics into all vehicles for automated emission testing and remote diagnostics. This would involve adding a radio transponder to cars to transmit VIN and DTCs wirelessly. While convenient, this raises privacy concerns.

Interestingly, while OBD2 was designed for repair shop diagnostics, its use for third-party data access has grown significantly. However, some automotive manufacturers are seeking to restrict this third-party access, potentially limiting the future utility of the standard obd2 pinout for broader data applications beyond diagnostics. The debate around data ownership and access continues to shape the future of OBD and vehicle data utilization.

Image depicting an OBD2 connector being removed from an electric vehicle, symbolizing the potential shift in data access and the challenges for standard OBD2 in the EV era.

Get our ‘Ultimate CAN Guide’

Want to become a CAN bus expert?

Get our 12 ‘simple intros’ in one 160+ page PDF:

Download now

CAN Bus – The Ultimate Guide Tutorial PDF

CAN Bus – The Ultimate Guide Tutorial PDF

OBD2 Standards: Pinout and Protocols

OBD2 operates as a higher-layer protocol, much like a language spoken over a communication channel. In the OBD2 context, CAN bus is the most common communication method, analogous to a phone line. OBD2 is comparable to other CAN-based protocols like J1939, CANopen, and NMEA 2000.

OBD2 standards comprehensively define the OBD2 connector obd2 pinout, lower-layer communication protocols, OBD2 Parameter IDs (PIDs), and more. These standards are structured according to the 7-layer OSI model. Notably, both SAE (US standards) and ISO (EU standards) contribute to OBD2 specifications, with some overlap and technical equivalence, such as SAE J1979 vs. ISO 15031-5 and SAE J1962 vs. ISO 15031-3, the latter being crucial for obd2 pinout definition.

Diagram illustrating the relationship between OBD2 and CAN bus within the 7-layer OSI model, highlighting relevant ISO and SAE standards.

Schematic diagram of a Type A OBD2 connector pinout, clearly labeling each pin and its function, essential for understanding the physical interface.

The OBD2 Connector Pinout: SAE J1962 Demystified

The 16-pin OBD2 connector, detailed in the SAE J1962 / ISO 15031-3 standard, provides a standardized way to access vehicle data. This connector is often referred to as the Data Link Connector (DLC). Understanding the obd2 pinout is fundamental for anyone working with OBD2 systems.

Here’s a closer look at the OBD2 pin connector and its key characteristics:

- Location: Typically found near the steering wheel, though its exact location can sometimes be hidden behind panels.

- Pin 16: Provides battery power, often active even when the ignition is off, crucial for powering OBD2 devices.

- Protocol Dependency: The function of specific pins within the obd2 pinout varies depending on the communication protocol used by the vehicle.

- CAN Bus Connection: In vehicles using CAN bus (the most common protocol), pins 6 (CAN-High) and 14 (CAN-Low) are essential for data communication.

Understanding the specific function of each pin in the obd2 pinout is critical for correctly interfacing with the OBD2 port and ensuring proper communication with the vehicle’s systems.

OBD2 Connector Types: Type A vs. Type B Pinout Variations

You might encounter two primary types of OBD2 connectors: Type A and Type B. Type A is predominantly used in cars and light-duty vehicles, while Type B is more common in medium and heavy-duty vehicles.

While both Type A and Type B connectors share a similar obd2 pinout structure, a key difference lies in their power supply outputs: 12V for Type A and 24V for Type B. Baud rates can also differ, with cars typically using 500K and heavy-duty vehicles often using 250K (though 500K is becoming more prevalent in newer heavy-duty vehicles).

Visually distinguishing them is straightforward: the Type B OBD2 connector has a distinct interrupted groove in the middle. Interestingly, a Type B OBD2 adapter cable is often compatible with both Type A and B sockets, whereas a Type A adapter will only fit into a Type A socket.

Diagram contrasting OBD2 Connector Type A and Type B, highlighting differences in pinout, voltage, and application in cars vs. trucks.

Conceptual image representing the relationship between OBD2 and CAN bus, emphasizing ISO 15765 as the standard for OBD over CAN.

OBD2 and CAN Bus: ISO 15765-4 and Pinout Configuration

Since 2008, CAN bus has been mandated as the lower-layer protocol for OBD2 in US vehicles according to ISO 15765. This standard, also known as Diagnostics over CAN (DoCAN), specifies how OBD2 operates on a CAN network. ISO 15765-4 defines restrictions on the CAN standard (ISO 11898) specifically for OBD2 applications, which directly impacts the obd2 pinout usage for CAN communication.

Key aspects of ISO 15765-4 related to the obd2 pinout and CAN communication include:

- CAN Bit-rate: Must be either 250K or 500K.

- CAN IDs: Supports both 11-bit and 29-bit CAN identifiers.

- Specific CAN IDs: Prescribed CAN IDs are used for OBD requests and responses via the obd2 pinout’s CAN High and Low pins.

- Data Length: Diagnostic CAN frames are limited to 8 bytes of data.

- Cable Length: OBD2 adapter cables should not exceed 5 meters.

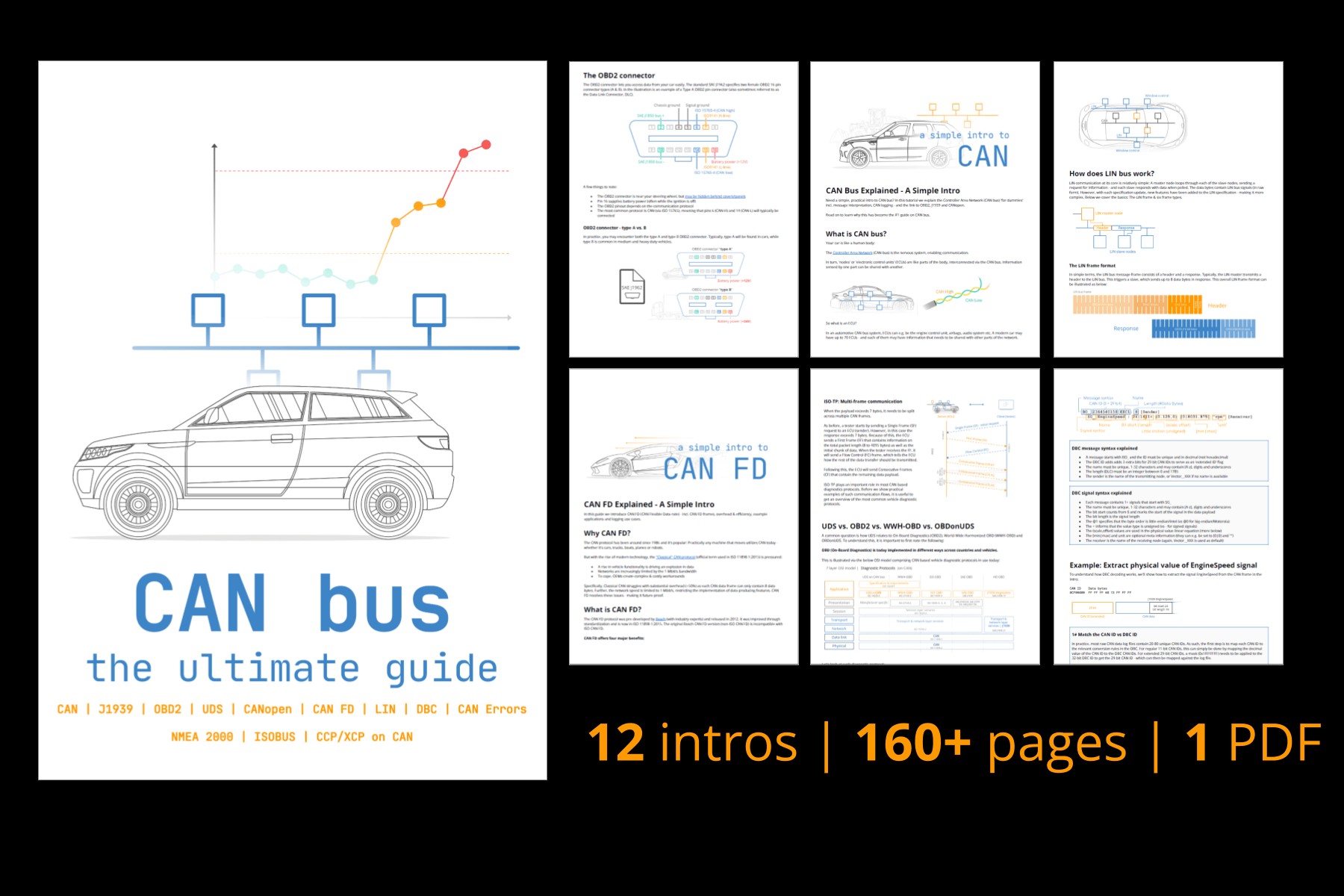

OBD2 CAN Identifiers: 11-bit and 29-bit and Pinout Usage

OBD2 communication via the obd2 pinout relies on request/response message exchanges over the CAN bus.

In most cars, 11-bit CAN IDs are used for OBD2. The ‘Functional Addressing’ ID, 0x7DF, is used to query all OBD2-compatible ECUs for data related to a requested parameter. ‘Physical Addressing’ requests, using CAN IDs 0x7E0-0x7E7, target specific ECUs, but are less commonly used.

ECUs respond with 11-bit IDs in the range 0x7E8-0x7EF. The most frequent response ID is 0x7E8 (Engine Control Module – ECM), followed by 0x7E9 (Transmission Control Module – TCM).

Some vehicles, particularly vans and medium/heavy-duty vehicles, may utilize extended 29-bit CAN identifiers for OBD2 communication via the obd2 pinout. The ‘Functional Addressing’ CAN ID in this case is 0x18DB33F1. Responses are typically seen with CAN IDs ranging from 0x18DAF100 to 0x18DAF1FF (commonly 18DAF110 and 18DAF11E). These 29-bit IDs are sometimes represented in the J1939 PGN format, specifically PGN 0xDA00 (55808), which is reserved for ISO 15765-2 in the J1939-71 standard.

Diagram illustrating the OBD2 request-response frame structure, showing the flow of data and parameters in OBD2 communication.

OBD2 OBD CAN bus Identifiers 7DF 7E8 7E0

OBD2 OBD CAN bus Identifiers 7DF 7E8 7E0

Comparison image contrasting OBD2 standard CAN bus communication with OEM-specific proprietary CAN protocols used within vehicles.

OBD2 vs. Proprietary CAN Protocols: Data Access Beyond the Pinout

It’s important to realize that OBD2 is not the primary communication system for your car’s ECUs. Automotive manufacturers (OEMs) implement their own proprietary CAN protocols for internal vehicle communication. These OEM-specific protocols are often unique to vehicle brand, model, and year. Accessing and interpreting this proprietary data typically requires reverse engineering, as it’s not openly documented.

When you connect a CAN bus data logger to your car’s OBD2 connector obd2 pinout, you might observe both OBD2 data and OEM-specific CAN data. OEM data is often broadcast at high rates (1000-2000 frames/second). However, in newer vehicles, a ‘gateway’ module may restrict access to OEM CAN data through the OBD2 port, allowing only OBD2 communication.

Think of OBD2 as a secondary, standardized communication layer that operates alongside the OEM’s primary, proprietary CAN protocol. The OBD2 connector obd2 pinout provides a standardized access point to this OBD2 layer, but may not grant access to the full breadth of vehicle communication data.

Bit-rate and ID Validation: Ensuring Correct Pinout Communication

OBD2 over CAN can use two bit rates (250K, 500K) and two CAN ID lengths (11-bit, 29-bit), resulting in four possible protocol combinations. Modern cars commonly use 500K and 11-bit IDs, but diagnostic tools should systematically determine the correct combination to ensure proper communication via the obd2 pinout.

ISO 15765-4 provides a recommended initialization sequence to automatically detect the correct protocol. This process relies on the mandatory OBD2 service response (mode 0x01 PID 0x00) and the detection of CAN error frames, which occur when using an incorrect bit rate.

Newer versions of ISO 15765-4 account for OBD communication via OBDonUDS as well as OBDonEDS. OBDonEDS (OBD on Emission Diagnostic Service, as per ISO 15031-5/SAE J1979) is prevalent in most non-EV cars, while WWH-OBD (World Wide Harmonized OBD) / OBDonUDS (OBD on Unified Diagnostic Service, as per ISO 14229, ISO 27145-3/SAE J1979-2) is primarily used in EU trucks and buses.

To differentiate between OBDonEDS and OBDonUDS, diagnostic tools may send UDS requests using 11-bit/29-bit functional address IDs for service 0x22 and data identifier (DID) 0xF810 (protocol identification). Vehicles supporting OBDonUDS must respond to this DID.

Flowchart illustrating the OBD2 bit-rate and CAN ID validation process as defined in ISO 15765-4, guiding diagnostic tools in establishing communication.

Diagram showcasing the five lower-layer OBD2 protocols, including CAN (ISO 15765) and older protocols like KWP2000, SAE J1850, and ISO 9141.

Five Lower-Layer OBD2 Protocols and Pinout Implications

While CAN (ISO 15765) is dominant today, older vehicles (pre-2008) may use other lower-layer protocols for OBD2. Knowing these protocols and their associated obd2 pinout configurations can be helpful when working with older cars. The obd2 pinout itself can sometimes give clues about the protocol used.

The five lower-layer OBD2 protocols are:

- ISO 15765 (CAN bus): Mandatory in US cars since 2008, and the most prevalent protocol today. Pins 6 and 14 of the obd2 pinout are used for CAN High and CAN Low respectively.

- ISO14230-4 (KWP2000): Keyword Protocol 2000, common in 2003+ Asian cars. Pin 7 (K-line) of the obd2 pinout is key for KWP2000 communication.

- ISO 9141-2: Used in EU, Chrysler, and Asian cars (2000-04). Similar to KWP2000, it uses pin 7 (K-line) and sometimes pin 15 (L-line) in the obd2 pinout.

- SAE J1850 (VPW – Variable Pulse Width Modulation): Primarily used in older GM vehicles. Pin 2 of the obd2 pinout is used for VPW signal.

- SAE J1850 (PWM – Pulse Width Modulation): Mostly found in older Ford vehicles. Pins 2 and 10 of the obd2 pinout are used for PWM signals.

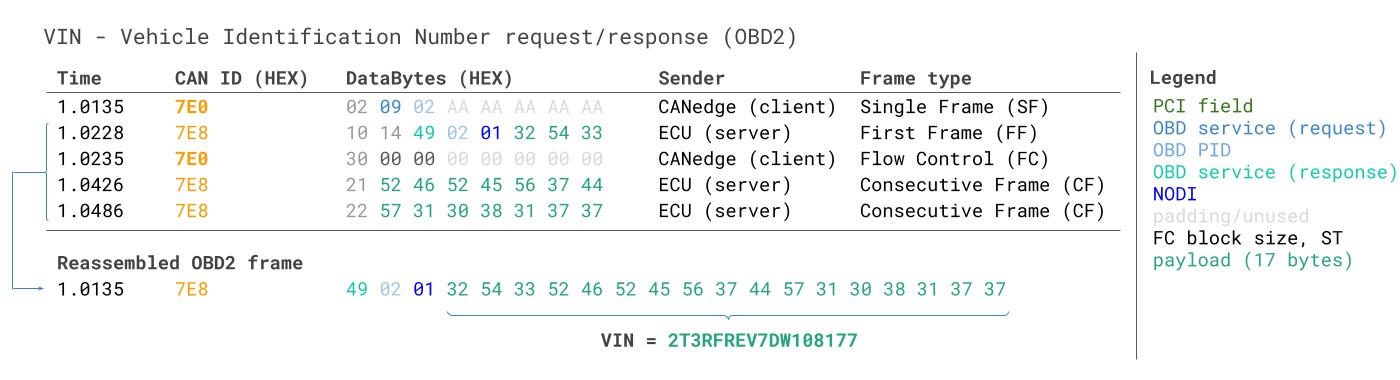

ISO-TP: Transporting OBD2 Messages Beyond 8 Bytes via the OBD2 Pinout

OBD2 communication over the obd2 pinout and CAN bus utilizes ISO-TP (ISO 15765-2) as the transport protocol. ISO-TP enables the transmission of data payloads exceeding the 8-byte limit of a standard CAN frame. This is essential for OBD2 functions like retrieving the Vehicle Identification Number (VIN) or Diagnostic Trouble Codes (DTCs), which often require more than 8 bytes of data. ISO-TP handles segmentation, flow control, and reassembly of these larger messages.

For smaller OBD2 data transmissions that fit within a single CAN frame, ISO-TP specifies the use of ‘Single Frame’ (SF) messages. In SF messages, the first data byte (PCI field) indicates the payload length, leaving 7 bytes for OBD2-related data within the CAN frame transmitted through the obd2 pinout.

Diagram illustrating the different frame types defined in ISO 15765-2 (ISO-TP) for OBD2 communication, including Single Frame, First Frame, Consecutive Frame, and Flow Control Frame.

Decoding OBD2 Diagnostic Messages: Pinout to Data Interpretation

To understand OBD2 communication on CAN, let’s examine a raw ‘Single Frame’ OBD2 CAN message transmitted via the obd2 pinout. A simplified OBD2 message structure includes a CAN identifier, a data length indicator (PCI field), and the data payload. The payload itself is structured into Mode, Parameter ID (PID), and data bytes.

Breakdown of an OBD2 message structure, showing the components of a raw OBD2 frame, including Mode, PID, and data bytes.

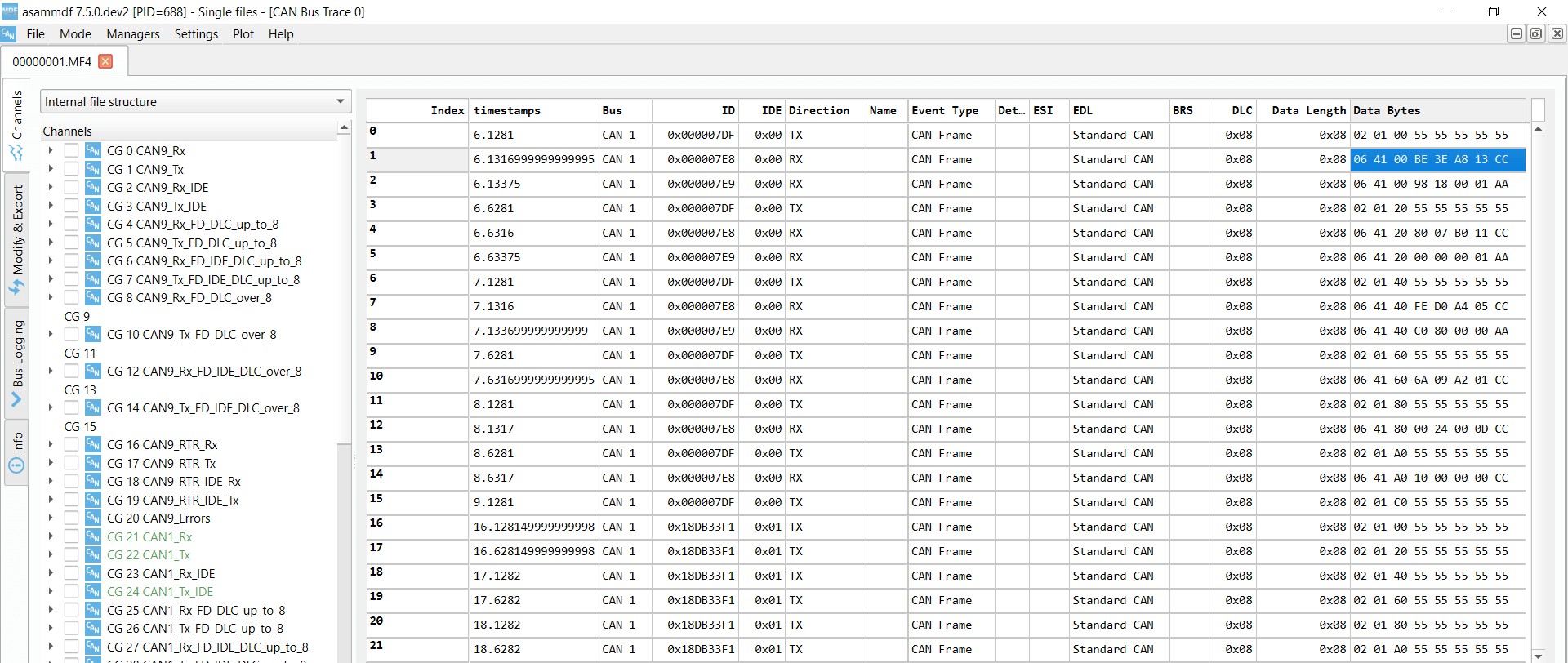

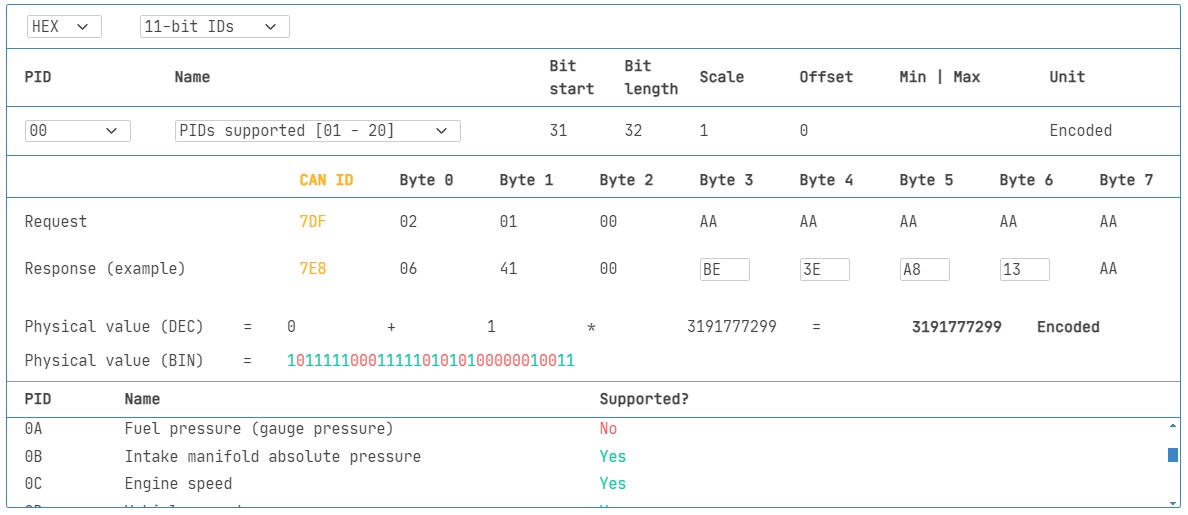

Example: OBD2 Request/Response via the OBD2 Pinout

Consider a practical example: requesting ‘Vehicle Speed’ via the obd2 pinout. An external tool sends a request message to the car using CAN ID 0x7DF and a 2-byte payload: Mode 0x01 and PID 0x0D. The car responds through the obd2 pinout using CAN ID 0x7E8 and a 3-byte payload, with the vehicle speed value in the 4th byte (0x32, which is 50 in decimal).

By consulting the OBD2 PID specifications for PID 0x0D, we can determine that the value 0x32 corresponds to a vehicle speed of 50 km/h. This demonstrates how data transmitted through the obd2 pinout is interpreted using OBD2 standards.

Example sequence of an OBD2 request (CAN ID 0x7DF) and response (CAN ID 0x7E8) for vehicle speed, illustrating the data exchange over the OBD2 pinout.

Detailed view of the OBD2 PID 0x0D (Vehicle Speed) example, showing the specific bytes and their interpretation in the request and response messages.

Chart outlining the 10 standard OBD2 service modes (or modes), including their descriptions and functionalities, such as retrieving current data, freeze frame data, and clearing DTCs.

The 10 OBD2 Services (Modes): Accessing Data via the OBD2 Pinout

OBD2 defines 10 diagnostic services, also known as modes, accessible through the obd2 pinout. Mode 0x01 is used for retrieving real-time data, while other modes are designed for accessing and clearing Diagnostic Trouble Codes (DTCs), retrieving freeze frame data, and more.

It’s important to note that vehicles are not required to support all 10 OBD2 modes, and manufacturers may also implement OEM-specific OBD2 modes beyond the standard set. In OBD2 messages, the mode is indicated in the second byte. In a request message, the mode is included directly (e.g., 0x01), while in the response, 0x40 is added to the mode value (e.g., 0x41).

OBD2 Parameter IDs (PIDs): Requesting Specific Data via the Pinout

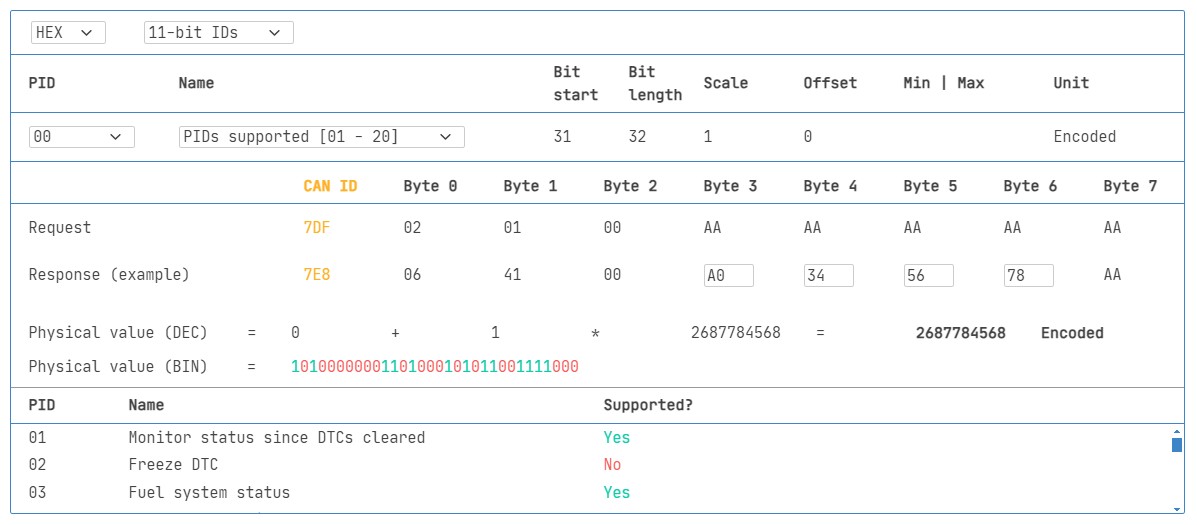

Within each OBD2 mode, Parameter IDs (PIDs) are used to specify the particular data parameter being requested via the obd2 pinout. For example, Mode 0x01 contains approximately 200 standardized PIDs for real-time data, covering parameters like speed, RPM, and fuel level. However, vehicles typically support only a subset of these PIDs.

One PID, PID 0x00 in Mode 0x01, is particularly significant. If an emissions-related ECU supports any OBD2 services, it must support Mode 0x01 PID 0x00. Responding to this PID, the ECU indicates its support for PIDs 0x01-0x20. PID 0x00 serves as a fundamental OBD2 compatibility test. Similarly, PIDs 0x20, 0x40, and so on, are used to determine support for subsequent PID ranges within Mode 0x01.

(Duplicate image, already used above)

OBD2 PID overview tool

OBD2 PID overview tool

Screenshot of an OBD2 PID overview tool, showcasing a user interface for browsing and selecting OBD2 PIDs within service 01.

Tip: OBD2 PID Overview Tool for Pinout Data Interpretation

SAE J1979 and ISO 15031-5 appendices provide scaling information for standard OBD2 PIDs, enabling the conversion of raw data received via the obd2 pinout into physical values. For quick PID lookups, utilize our OBD2 PID overview tool. It assists in constructing OBD2 request frames and dynamically decoding OBD2 responses, simplifying the process of interpreting data obtained through the obd2 pinout.

OBD2 PID overview tool

Logging and Decoding OBD2 Data: Practical Pinout Applications

Let’s explore a practical example of logging OBD2 data using the CANedge CAN bus data logger. The CANedge allows custom CAN frame transmission, making it suitable for OBD2 data logging and interaction via the obd2 pinout.

Connecting the CANedge to your vehicle is straightforward using our OBD2-DB9 adapter cable.

Diagram illustrating an OBD2 data logger setup, showing the CANedge connected to the OBD2 port and requesting PID data.

OBD2 bit rate test

OBD2 bit rate test

Screenshot of a bit-rate validation test for OBD2 communication, showing successful CAN frame transmission at 500K.

OBD2 Supported PIDs Test

OBD2 Supported PIDs Test

Screenshot from asammdf software displaying responses to ‘Supported PIDs’ requests, used to identify which PIDs a vehicle supports.

Review supported PIDs via OBD2 lookup tool

Review supported PIDs via OBD2 lookup tool

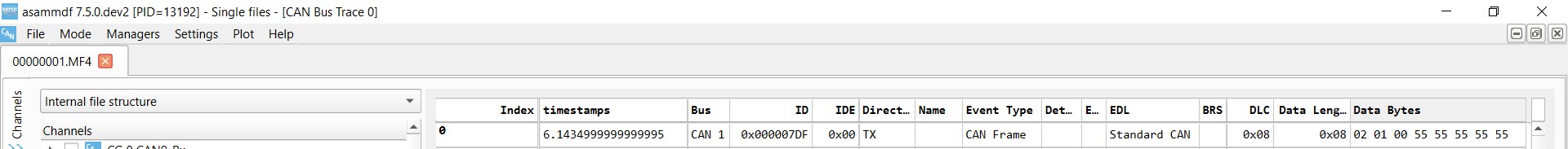

#1: Bit-rate, ID, and Supported PID Testing via the OBD2 Pinout

ISO 15765-4 outlines the process to determine the correct bit-rate and IDs for OBD2 communication with a vehicle. You can use the CANedge to perform these tests:

- Bit-rate Test: Send a CAN frame at 500K and check for successful transmission (if unsuccessful, try 250K).

- Subsequent Communication: Use the validated bit-rate for all further communication via the obd2 pinout.

- Supported PIDs Request: Send multiple ‘Supported PIDs’ requests and analyze the responses.

- ID Determination: Response IDs indicate 11-bit vs. 29-bit CAN ID usage.

- PID Support: Response data reveals which PIDs the vehicle supports.

Plug-and-play configurations are available to simplify these tests. Most post-2008 non-EV cars support 40-80 PIDs using a 500K bit-rate, 11-bit CAN IDs, and the OBD2/OBDonEDS protocol. As seen in the asammdf GUI screenshot, multiple ECUs may respond to a single OBD request when using the 0x7DF request ID. Using ‘Physical Addressing’ with IDs like 0x7E0 can reduce bus load by targeting specific ECUs.

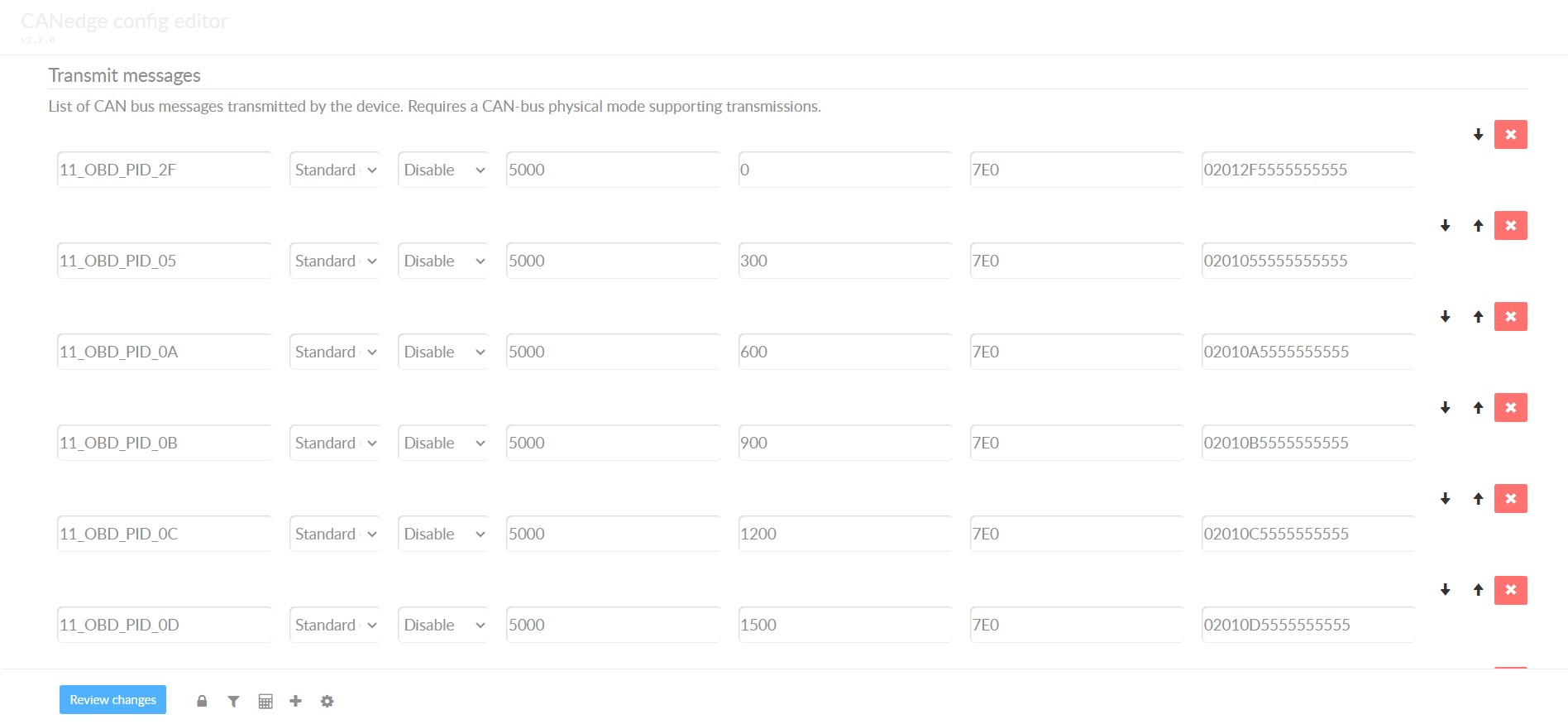

#2: Configuring OBD2 PID Requests for Efficient Pinout Data Logging

Once you’ve identified supported OBD2 PIDs, bit-rate, and CAN IDs for your vehicle, configure your data logger to request specific PIDs of interest. Consider these factors for optimal OBD2 data logging via the obd2 pinout:

- CAN IDs: Switch to ‘Physical Addressing’ request IDs (e.g., 0x7E0) to minimize multiple responses per request.

- Request Spacing: Introduce a 300-500 ms delay between OBD2 requests to avoid overwhelming ECUs.

- Battery Management: Implement triggers to stop transmissions when the vehicle is inactive, preventing battery drain.

- Data Filtering: Apply filters to record only OBD2 responses if OEM-specific CAN data is also present.

With these configurations, your data logger is ready to efficiently record raw OBD2 data through the obd2 pinout.

obd2-transmit-list-example-canedge

obd2-transmit-list-example-canedge

Example of a CANedge transmit list configuration for OBD2 PID requests, showing PID values and request parameters.

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

Screenshot of asammdf software displaying decoded and visualized OBD2 data, plotted from a CAN bus DBC file, showing interpretable vehicle parameters.

#3: DBC Decoding of Raw OBD2 Data from the Pinout

To analyze and visualize logged OBD2 data, you need to decode the raw data into physical values. Decoding information is found in ISO 15031-5/SAE J1979 and online resources like Wikipedia. For convenience, a free OBD2 DBC file is available, simplifying DBC decoding in CAN bus software tools.

Decoding OBD2 data is more complex than standard CAN signal decoding because different OBD2 PIDs can share the same CAN ID (e.g., 0x7E8). Therefore, signal identification requires considering the CAN ID, OBD2 mode, and OBD2 PID. This form of multiplexing, termed ‘extended multiplexing’, is handled in DBC files.

CANedge: Your OBD2 Data Logger for Pinout Data Acquisition

The CANedge facilitates easy recording of OBD2 data to SD cards (8-32 GB). Connect it to a vehicle’s obd2 pinout to start logging and use free software/APIs and our OBD2 DBC file for data decoding.

OBD2 logger intro CANedge

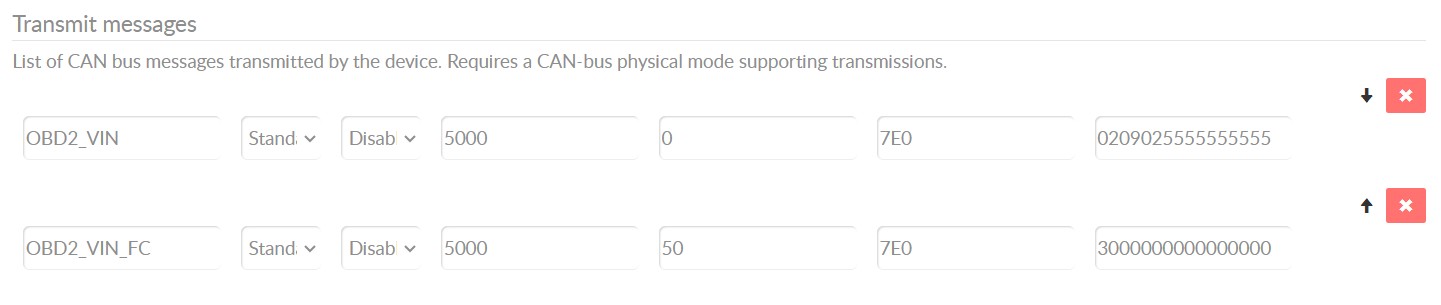

OBD2 Multi-Frame Examples: ISO-TP in Action via the Pinout

Most OBD2 communication is single-frame, but multi-frame communication via ISO-TP is necessary for larger data sets. Multi-frame OBD2 communication requires flow control frames. A static flow control frame can be transmitted approximately 50 ms after the initial request frame, as demonstrated in the CANedge configuration example. CAN software/API tools supporting ISO-TP, like CANedge MF4 decoders, are needed for processing multi-frame OBD2 responses.

OBD2-multi-frame-request-message-vehicle-identification-number

OBD2-multi-frame-request-message-vehicle-identification-number

Example of an OBD2 multi-frame request message for Vehicle Identification Number (VIN), showing the structure of a multi-frame request.

Example 1: OBD2 Vehicle Identification Number (VIN) Retrieval via the Pinout

Retrieving the VIN is crucial for telematics and diagnostics. Using OBD2, you can request the VIN (mode 0x09, PID 0x02) via the obd2 pinout:

VIN Vehicle Identification Number OBD2 Example multi-frame

VIN Vehicle Identification Number OBD2 Example multi-frame

The tool sends a Single Frame request. The vehicle responds with a First Frame indicating the total data length, mode, PID, and Number Of Data Items (NODI). Subsequent bytes contain the VIN, which can be converted from HEX to ASCII.

Example 2: OBD2 Multi-PID Request (6x) – Advanced Pinout Data Acquisition

OBD2 allows requesting up to 6 Mode 0x01 PIDs in a single request frame. The ECU responds with data for supported PIDs, potentially across multiple frames. While efficient, this method complicates data decoding and is not generally recommended for practical data logging due to DBC file limitations.

Requesting multiple PIDs in one request

Requesting multiple PIDs in one request

Decoding multi-PID responses with generic OBD2 DBC files is challenging. Extended multiplexing and payload position variations make DBC-based decoding difficult to generalize across vehicles. While custom scripts and recording request messages can help, this approach is complex for large-scale applications.

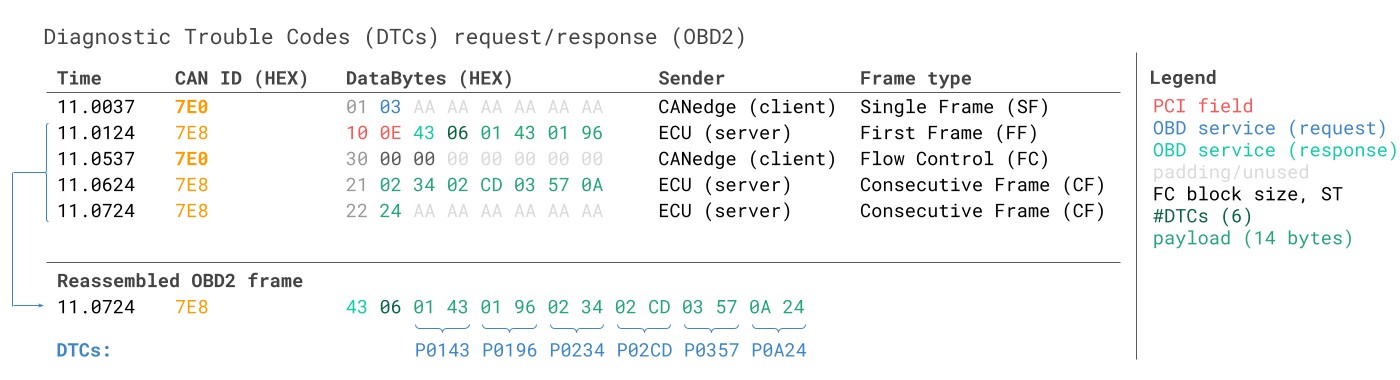

Example 3: OBD2 Diagnostic Trouble Codes (DTCs) – Pinout Access to Fault Codes

OBD2 mode 0x03 (‘Show stored Diagnostic Trouble Codes’) is used to retrieve emissions-related DTCs. The request doesn’t include a PID. The ECU responds with the number of stored DTCs and the DTC codes themselves (2 bytes per DTC). Multi-frame responses are necessary when more than 2 DTCs are stored.

DTCs are 2-byte values, categorized and coded as per ISO 15031-5/ISO 15031-6. Decoded DTC values can be looked up using OBD2 DTC lookup tools like repairpal.com.

Diagram explaining the structure and decoding of OBD2 Diagnostic Trouble Codes (DTCs), showing the breakdown of the 2-byte DTC value.

OBD2 Diagnostic Trouble Codes DTC CAN Bus Request Response Example

OBD2 Diagnostic Trouble Codes DTC CAN Bus Request Response Example

OBD2 Data Logging Use Cases: Leveraging the OBD2 Pinout

OBD2 data, accessed via the obd2 pinout, has numerous applications in cars and light trucks:

Icon representing OBD2 data logging in a car, symbolizing the use of OBD2 for vehicle data acquisition.

Logging data from cars:

OBD2 data can be used for fuel efficiency analysis, driving behavior improvement, prototype testing, and insurance telematics.

obd2 logger

Icon for real-time OBD2 streaming diagnostics, illustrating the use of OBD2 for live vehicle data monitoring.

Real-time car diagnostics:

OBD2 interfaces enable real-time streaming of human-readable data for diagnosing vehicle issues.

obd2 streaming

Icon depicting OBD2 data logging for predictive maintenance, showing data being transmitted to the cloud for analysis.

Predictive maintenance:

Cloud-connected IoT OBD2 loggers can monitor vehicle health for predictive maintenance and breakdown prevention.

predictive maintenance

Icon representing a black box CAN logger, symbolizing the use of OBD2 data for vehicle event recording and analysis.

Vehicle blackbox logger:

OBD2 loggers can serve as vehicle ‘black boxes’ for incident analysis, insurance claims, and diagnostics.

can bus blackbox

Do you have an OBD2 data logging use case? Reach out for free sparring!

Contact us

For more intros, see our guides section – or download the ‘Ultimate Guide’ PDF.

Need to log/stream OBD2 data?

Get your OBD2 data logger today!

Buy now Contact us

Recommended for you

OBD2 DATA LOGGER: EASILY LOG & CONVERT OBD2 DATA

CANedge2 – Dual CAN Bus Telematics Dongle CANEDGE2 – PRO CAN IoT LOGGER

CANedge2 – Dual CAN Bus Telematics Dongle CANEDGE2 – PRO CAN IoT LOGGER

[