Modern vehicles are sophisticated machines, packed with sensors and control units far beyond what cars of the 1990s possessed. This complexity means that a wealth of potential issues can be identified simply by interpreting error codes. This is where On-Board Diagnostics (OBD2) scanners become invaluable tools for car owners and enthusiasts alike.

Learning how to use an OBD2 scanner can save you considerable time and money by empowering you to understand your car’s health. Here’s a comprehensive guide on everything a driver needs to know about using these devices effectively.

Get report

Understanding the Function of an OBD2 Scanner

An OBD2 scanner is a diagnostic tool that connects to a specialized port within your car to gather data from its various control units. This data includes crucial fault codes as well as real-time information, known as live data, encompassing readings for pressure, temperature, and speed, among other parameters.

Mechanic using an OBD2 scanner to perform computer diagnostics on a car.

Mechanic using an OBD2 scanner to perform computer diagnostics on a car.

Source: Flickr / shixart1985

The information collected by an OBD2 scanner originates from numerous sensors distributed throughout the vehicle. Fault codes typically arise when a sensor reading falls outside of the acceptable range or when a sensor ceases to respond altogether.

More advanced OBD2 diagnostic tools offer enhanced capabilities, including performing service functions and even coding. Coding becomes necessary when replacing specific components in modern vehicles, ensuring the new part integrates seamlessly with the car’s electronic systems.

The implementation of on-board diagnostics became mandatory for all cars manufactured from 1996 in the United States and from 2004 in Europe, making OBD2 scanners universally applicable to modern vehicles.

Exploring the Types of OBD2 Scanners Available

The market presents a wide array of OBD2 scanners, catering to different needs and budgets.

For users seeking a basic and economical option, Bluetooth OBD2 code readers are an excellent starting point. These compact devices pair with your smartphone, often costing very little, and provide the ability to read fault codes and access basic live data. This makes them a convenient and accessible choice for the average driver for quick diagnostics.

For individuals who are more inclined towards DIY car repairs, investing in a more feature-rich OBD2 scanner is advisable. These scanners, typically priced starting around $100 and increasing with added functionalities, not only read fault codes and live data but also offer capabilities such as resetting service reminders and activating service functions necessary for tasks like replacing brake pads.

Professional mechanics, however, often require tools that go beyond the capabilities of standard OBD2 scanners. While ordinary scanners are helpful, professional-grade OBD2 diagnostic tools offer extensive coding and programming possibilities, essential for tackling a wide spectrum of automotive issues, from routine oil changes to complex engine replacements.

With the appropriate professional tools, a skilled automotive technician can fine-tune virtually every customizable setting within a modern car’s electronic systems. However, these advanced tools come with a significant price tag, often costing thousands of dollars, and are generally too intricate for casual users.

Step-by-Step Guide: How to Read OBD2 Fault Codes

Reading fault codes is the foundational step in OBD2 diagnostics. Mastering this process is essential for anyone wanting to utilize an OBD2 scanner effectively. While the specific controls may vary across different models of diagnostic tools, the fundamental procedure remains consistent.

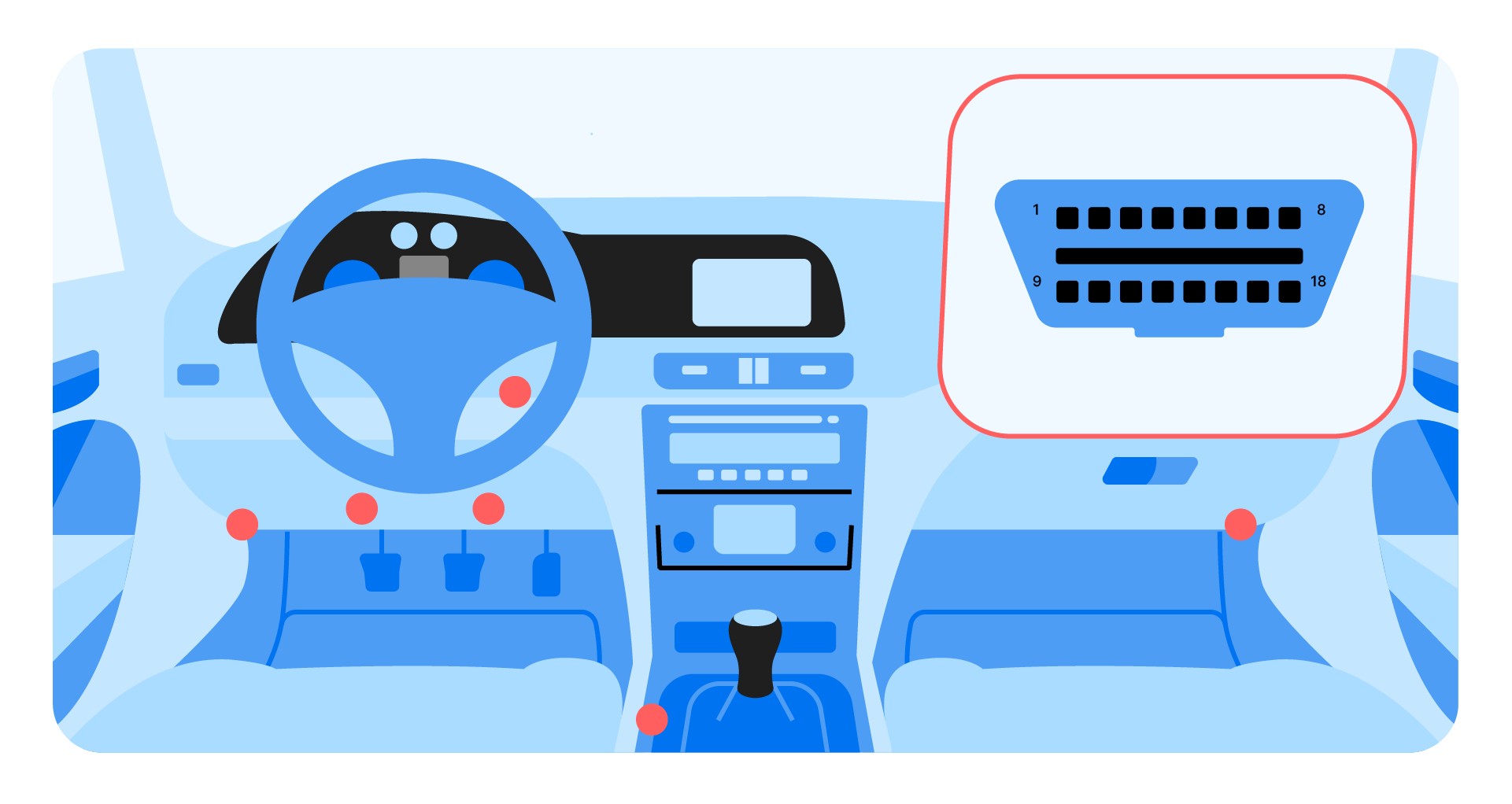

1. Locate the OBD2 Port

Every modern car is equipped with an OBD2 port. This port is typically located beneath the steering wheel or within the center console area. Often, the OBD2 port is concealed by a small plastic cover. Identify and access this port to proceed with connecting your scanner.

Location of the OBD2 port in a car, typically under the steering wheel.

Location of the OBD2 port in a car, typically under the steering wheel.

Source: carVertical

Many contemporary OBD2 scanners and code readers utilize Bluetooth technology for wireless connectivity. If you are using a Bluetooth scanner, ensure it is properly paired with your device at this stage.

2. Turn On the Ignition

Computer diagnostics via an OBD2 scanner necessitate that the car’s ignition is turned on. Before initiating a scan, turn the ignition to the ‘on’ position. To minimize electrical load during the diagnostic process, it’s recommended to turn off unnecessary electrical consumers such as headlights, the radio, and air conditioning.

While most vehicles allow fault code scanning with the engine running, fault codes are stored in the car’s computer memory and will persist until manually cleared. Starting the engine may be more relevant when you intend to observe live data readings.

3. Select Your Vehicle

Once your OBD2 scanner is connected and the ignition is on, the next step is to input your vehicle’s specific details, including make, model, and year. This information is crucial for the diagnostic tool to accurately recognize the car’s control units and correctly interpret the data.

Many modern diagnostic tools are equipped with an automatic vehicle identification system that can automatically detect the car’s VIN (Vehicle Identification Number) and configure the necessary settings. If automatic VIN detection is unsuccessful, you typically have the option to manually enter the VIN.

4. Initiate the Scan for Fault Codes

Navigate to the fault code reading option on your OBD2 scanner. Most scanners provide options to select specific control units to scan or to perform a comprehensive scan of all available control units. For a general diagnostic overview, a full system scan is often the most thorough approach.

If you encounter difficulty in locating these options within your scanner’s interface, consult the integrated help section or the user manual that came with your device for detailed instructions.

The duration of a full system scan can vary depending on the car’s model and the number of control units, typically ranging from a few seconds to several minutes.

5. Interpret the Revealed Fault Codes

The fault codes displayed after a scan are the key indicators of issues that may be triggering warning lights on your dashboard. Some fault codes are quite explicit and straightforward, such as “00287 – ABS Wheel Speed Sensor; Rear Right.” This code clearly suggests a problem with the rear right ABS wheel speed sensor, likely requiring replacement.

However, it’s important to understand that the underlying causes of fault codes can often be more complex than they initially appear. For instance, a code like “P0171 – System Too Lean (Bank 1)” indicates that the engine’s air-fuel mixture is too lean. This condition could stem from a variety of issues, including a clogged fuel filter, a failing fuel pump, vacuum leaks, malfunctions in various sensors, and other potential problems.

Pro Tip: Leveraging Live Data for Deeper Diagnostics

Beyond fault codes, the ability to access and interpret live data significantly enhances your diagnostic capabilities. Most OBD2 scanners provide a live data section, allowing you to monitor real-time parameters from the car’s sensors. How can this be beneficial?

Consider a scenario where your car is experiencing a noticeable reduction in power, and the only fault code present is a generic notification indicating that the vehicle is in limp mode (reduced power mode). In such cases, live data can be invaluable. You can use your OBD2 scanner to monitor parameters such as fuel pressure, boost pressure (for turbocharged engines), intake airflow, and intake manifold pressure to see if these readings are within normal operating ranges. Deviations from expected values can provide crucial clues to the root cause of the performance issue.

Close-up of an OBD2 scanner displaying live data readings during car diagnostics.

Close-up of an OBD2 scanner displaying live data readings during car diagnostics.

Source: Flickr / comedy_nose

While OBD2 scanners offer powerful diagnostic features, interpreting fault codes and effectively utilizing live data can sometimes require a deeper understanding of automotive systems. Don’t hesitate to seek assistance from online resources or automotive professionals if you find yourself needing help to decipher the information provided by your scanner and pinpoint the source of a problem.

OBD2 Scanners: An Indispensable Tool for Used Car Buyers

The used car market can present potential pitfalls for buyers. Dishonest sellers may attempt to conceal vehicles with hidden issues, ranging from problematic histories to electrical faults or even legal encumbrances.

While obtaining a vehicle history report is a crucial step in assessing a used car, a thorough pre-purchase inspection is essential to mitigate the risk of unexpected and costly repairs.

Before finalizing the purchase of a used vehicle, it is always recommended to obtain a history report and, importantly, to check for fault codes using an OBD2 scanner. If you are not yet equipped with an OBD2 scanner or are unsure about how to use one effectively, it is prudent to have the car professionally inspected by a qualified mechanic before making a purchase decision.

Check Your VIN

Avoid potential costly problems by checking a vehicle’s history. Get a report instantly!

What to Do After Reading Fault Codes: Clearing and Resolution

Scanning for fault codes is a diagnostic step, and fault codes themselves often do not directly pinpoint the exact component needing replacement. Even when a diagnostic scan indicates a potential issue with, for example, a mass airflow sensor, experienced automotive technicians typically perform further testing using tools like multimeters. This is done to confirm that the sensor is indeed faulty and to rule out other potential causes, such as wiring problems, loose connections, or corrosion, which can sometimes trigger similar fault codes. Replacing parts based solely on fault codes without thorough verification can lead to misdiagnosis and unnecessary expenses.

Once the underlying problem has been identified and rectified, it’s necessary to re-scan for fault codes to ensure that the issue has been resolved. If the fault code no longer appears after the repair, it is a strong indication that the problem has been successfully addressed, and the vehicle is ready to be driven.

Frequently Asked Questions

Evaldas Zabitis, expert automotive content creator at cardiagnosticnearme.com.

Evaldas Zabitis, expert automotive content creator at cardiagnosticnearme.com.

Article by

Evaldas Zabitis

Evaldas has a long-standing passion for cars and extensive experience in the automotive field. He is dedicated to making complex automotive topics accessible to a wider audience.