As a car owner or automotive technician, understanding your vehicle’s health is crucial. Modern vehicles are equipped with sophisticated On-Board Diagnostic (OBD2) systems that monitor various parameters and can detect malfunctions. When an issue arises, the system generates Diagnostic Trouble Codes (DTCs), often referred to as Obd2 Dtcs. These codes are your car’s way of communicating problems, and deciphering them is the first step towards effective vehicle repair and maintenance.

This guide provides a comprehensive overview of OBD2 DTCs, explaining what they are, how to interpret them, and their significance in automotive diagnostics. We will delve into the structure of DTCs, common categories, and how to use this information to diagnose and resolve vehicle issues effectively.

Understanding OBD2 and Diagnostic Trouble Codes (DTCs)

OBD2, or On-Board Diagnostics II, is a standardized system implemented in vehicles to monitor engine and emission control systems. It’s designed to detect malfunctions and alert the driver through the check engine light or malfunction indicator lamp (MIL) on the dashboard. When the OBD2 system detects a problem outside of normal operating parameters, it stores a corresponding DTC.

These OBD2 DTCs are essentially codes that pinpoint the area of the detected problem. They are not specific fixes, but rather starting points for diagnosis. Think of them as symptom indicators rather than definitive diagnoses. A mechanic uses an OBD2 scanner to retrieve these codes from the vehicle’s computer system, helping them understand what part of the vehicle is experiencing issues.

Does Your Car Use OBD2 and Generate OBD2 DTCs?

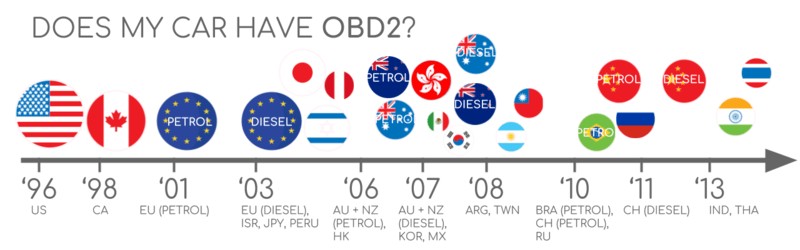

The likelihood is high that your car is OBD2 compliant and capable of generating OBD2 DTCs. OBD2 became mandatory in the United States for all cars and light trucks in 1996. The European Union followed suit, requiring OBD2 for gasoline cars in 2001 and diesel cars in 2003 (EOBD). By 2008, CAN bus became the mandated communication protocol for OBD2 in US vehicles.

Compliance timeline for OBD2 in vehicles across regions

Compliance timeline for OBD2 in vehicles across regions

While almost all modern non-electric cars support OBD2, older vehicles with a 16-pin OBD2 connector might not fully comply with the OBD2 standard. Compliance is largely determined by the vehicle’s manufacturing date and the market where it was initially sold.

The History and Evolution of OBD2 DTC Standards

The origin of OBD2 and consequently OBD2 DTCs can be traced back to California. The California Air Resources Board (CARB) mandated OBD in all new cars starting from 1991 for emission control. This was a crucial step towards standardized vehicle diagnostics.

The Society of Automotive Engineers (SAE) played a significant role in formalizing the standard, leading to standardized DTCs and the OBD connector across different car manufacturers through SAE J1962. This standardization made it easier for mechanics and technicians to diagnose vehicles regardless of the brand.

The rollout of OBD2 was a phased process:

- 1996: OBD2 mandated in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline vehicles.

- 2003: Extended to diesel vehicles in the EU (EOBD).

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US vehicles mandated to use ISO 15765-4 (CAN) as the OBD2 communication foundation.

- 2010: OBD2 became mandatory for heavy-duty vehicles in the US.

This history highlights the increasing importance of standardized diagnostics and OBD2 DTCs in vehicle maintenance and environmental regulation.

The Future of OBD and DTCs: OBD3 and Beyond

While OBD2 remains the current standard, the automotive industry is evolving. Interestingly, electric vehicles (EVs) are not obligated to support OBD2 in its traditional form for emissions control, as their emission profiles are fundamentally different from internal combustion engine vehicles. Most modern EVs do not support standard OBD2 requests, opting instead for OEM-specific UDS communication protocols. This presents challenges for generic diagnostic tools but opens avenues for specialized EV diagnostic approaches.

Emerging standards like WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) are being developed to enhance OBD communication, utilizing the UDS protocol for more streamlined and data-rich diagnostics. These advancements aim to address the limitations of current OBD2 implementations in terms of data richness and communication protocols.

The concept of OBD3 envisions integrating telematics into all vehicles, potentially enabling remote diagnostics and emissions monitoring. This could involve using a radio transponder to transmit vehicle identification numbers (VIN) and DTCs wirelessly to central servers for automated checks. While this offers convenience and efficiency, it also raises concerns about data privacy and surveillance.

OBD2 Standards and Protocols: Setting the Stage for DTC Communication

OBD2 operates as a higher-layer protocol, functioning like a language for vehicle diagnostics. It often uses CAN (Controller Area Network) bus as its communication method, similar to how a phone uses a network for communication. This is analogous to other CAN-based higher-layer protocols such as J1939, CANopen, and NMEA 2000.

The OBD2 standards encompass specifications for the OBD2 connector, lower-layer communication protocols, OBD2 Parameter IDs (PIDs), and the structure for transmitting OBD2 DTCs. These standards are defined by both SAE and ISO, reflecting standards originating in the US (SAE) and Europe (ISO). Many of these standards are technically equivalent, such as SAE J1979 and ISO 15031-5 for diagnostic services, and SAE J1962 and ISO 15031-3 for the OBD connector.

The OBD2 Connector: Accessing DTCs and Vehicle Data

The 16-pin OBD2 connector, standardized under SAE J1962 / ISO 15031-3, provides a standardized physical interface to access vehicle data, including OBD2 DTCs.

Key features of the OBD2 connector include:

- Location near the steering wheel, though sometimes hidden.

- Pin 16 providing battery power, even when the ignition is off.

- Pinout configuration dependent on the communication protocol used.

- Common use of CAN bus as the lower-layer protocol, utilizing pins 6 (CAN-H) and 14 (CAN-L).

OBD2 Connector Types: Type A vs. Type B

Two main types of OBD2 connectors exist: Type A and Type B. Type A is commonly found in cars and light vehicles, while Type B is prevalent in medium and heavy-duty vehicles.

While both types share similar pinouts for data communication, they differ primarily in power supply output (12V for Type A, 24V for Type B) and often baud rates (500K for cars, 250K or 500K for heavy-duty vehicles). Type B connectors feature an interrupted groove, allowing Type B adapter cables to be compatible with both Type A and Type B sockets, but Type A adapters are not compatible with Type B sockets.

OBD2 Communication over CAN Bus and DTC Transmission

Since 2008, CAN bus has become the mandatory lower-layer protocol for OBD2 in US vehicles, as specified by ISO 15765-4 (Diagnostics over CAN or DoCAN). ISO 15765-4 standardizes the CAN interface for diagnostic equipment, focusing on the physical, data link, and network layers.

Key specifications of OBD2 over CAN bus include:

- CAN bus bit rates of 250K or 500K.

- Support for both 11-bit and 29-bit CAN identifiers.

- Specific CAN IDs designated for OBD requests and responses, including DTC requests.

- Diagnostic CAN frame data length limited to 8 bytes.

- Maximum OBD2 adapter cable length of 5 meters.

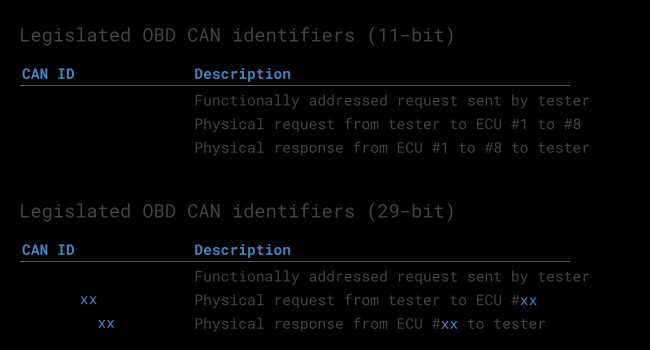

OBD2 CAN Identifiers and DTC Requests

OBD2 communication, including DTC requests and responses, is based on a request-response message exchange. In most cars, 11-bit CAN IDs are used for OBD2 communication. The ‘Functional Addressing’ ID 0x7DF is commonly used to query all OBD2-compatible ECUs for data, including DTCs. ‘Physical Addressing’ using CAN IDs 0x7E0-0x7E7 allows requests to specific ECUs, though this is less common for general DTC requests.

ECUs typically respond with 11-bit IDs in the range 0x7E8-0x7EF, with 0x7E8 (Engine Control Module – ECM) and 0x7E9 (Transmission Control Module – TCM) being frequent response IDs. Some vehicles, particularly vans and heavy-duty vehicles, may utilize 29-bit CAN identifiers for OBD2 communication. In these cases, the ‘Functional Addressing’ CAN ID is 0x18DB33F1, with responses in the range 0x18DAF100 to 0x18DAF1FF (e.g., 0x18DAF110, 0x18DAF11E).

Table summarizing OBD2 OBD CAN bus Identifiers like 7DF, 7E8, and 7E0

Table summarizing OBD2 OBD CAN bus Identifiers like 7DF, 7E8, and 7E0

OBD2 vs. OEM-Specific CAN Protocols and DTCs

It’s important to understand that OBD2 is an additional diagnostic protocol running alongside the OEM-specific CAN protocols that control the vehicle’s core functions. OEMs implement proprietary CAN protocols for their ECUs to operate, and these protocols are vehicle brand, model, and year-specific. OBD2 is designed as a standardized interface for accessing emissions-related diagnostic information, including OBD2 DTCs, by external tools.

When you connect a CAN bus data logger or OBD2 scanner to your vehicle’s OBD2 port, you might also observe OEM-specific CAN data being broadcast, but this data is typically encrypted or requires proprietary knowledge to interpret. In many newer vehicles, a gateway module restricts access to OEM-specific CAN data through the OBD2 port, allowing only standardized OBD2 communication, including access to OBD2 DTCs.

Decoding OBD2 DTCs: Message Structure and Interpretation

OBD2 DTCs are transmitted within OBD2 messages, which are structured according to SAE J1979 and ISO 15031-5 standards. A simplified OBD2 message includes an identifier, data length (PCI field), and data payload. The data payload typically contains the Mode, Parameter ID (PID), and data bytes.

Example: Requesting and Receiving OBD2 DTCs

To retrieve OBD2 DTCs, a diagnostic tool sends a request message to the vehicle. For example, to request ‘Show stored Diagnostic Trouble Codes’ (Mode 0x03), the tool sends a request with CAN ID 0x7DF and two payload bytes: Mode 0x03 and typically a PID of 0x00 (as no specific PID is needed for this mode).

The vehicle responds with a message, often via CAN ID 0x7E8, containing the number of DTCs stored and the DTCs themselves, each DTC typically encoded in two bytes. The structure and interpretation of these DTC bytes are crucial for understanding the nature of the detected faults.

Understanding OBD2 Service Modes and DTCs

OBD2 defines 10 diagnostic services or modes, each identified by a mode number (e.g., 0x01, 0x03, 0x09). Mode 0x03, specifically, is used to “Show stored Diagnostic Trouble Codes.” Other modes are used for retrieving real-time data (Mode 0x01), clearing DTCs (Mode 0x04), and accessing freeze frame data (Mode 0x02), among others.

Vehicles are not required to support all OBD2 modes, and manufacturers may implement additional OEM-specific modes beyond the 10 standardized ones. In OBD2 messages, the mode is indicated in the second byte of the data payload. In a request, the mode is included directly (e.g., 0x03), while in the response, 0x40 is added to the mode value (e.g., resulting in 0x43 for a response to mode 0x03).

Decoding OBD2 Diagnostic Trouble Codes (DTCs) Structure

OBD2 DTCs are typically two-byte codes. According to ISO 15031-5 and ISO 15031-6, the first byte and the first two bits of the second byte define the DTC category, while the remaining bits form a 4-digit hexadecimal code that specifies the fault.

The first character of a DTC is a letter indicating the system:

- P – Powertrain (engine, transmission)

- C – Chassis (braking, suspension)

- B – Body (interior, airbags)

- U – Network/User Communication

The second character is a digit indicating whether the code is generic (standardized across manufacturers) or manufacturer-specific:

- 0 – Generic OBD2 DTC

- 1 – Manufacturer-specific DTC

The third character is a digit indicating the subsystem:

- 0 – Fuel and Air Metering and Auxiliary Emission Controls

- 1 – Fuel and Air Metering

- 2 – Fuel and Air Metering – Injector Circuit

- 3 – Ignition System or Misfire

- 4 – Auxiliary Emission Controls

- 5 – Vehicle Speed Controls and Idle Control System

- 6 – Computer Output Circuit

- 7 – Transmission

The last two characters are hexadecimal digits (0-9, A-F) that specify the specific fault within the subsystem.

Example: Decoding a DTC – P0301

Let’s take the DTC P0301 as an example:

- P – Powertrain (related to engine or transmission)

- 0 – Generic OBD2 DTC (standard code)

- 3 – Ignition System or Misfire subsystem

- 01 – Specific fault: Cylinder 1 Misfire Detected

Therefore, P0301 indicates a generic powertrain-related fault specifically identifying a misfire in cylinder 1.

Practical Steps for Retrieving and Interpreting OBD2 DTCs

-

Connect an OBD2 Scanner: Plug an OBD2 scanner into your vehicle’s OBD2 port. These scanners range from basic handheld devices to advanced professional tools.

-

Turn Ignition ON: Turn your vehicle’s ignition to the ‘ON’ position but do not start the engine (unless your scanner instructs otherwise).

-

Read DTCs: Navigate the scanner’s menu to the ‘Read Codes’ or ‘Diagnostic Codes’ option. The scanner will communicate with the vehicle’s computer and display any stored DTCs.

-

Record DTCs: Note down all the DTCs displayed. It’s helpful to record them exactly as shown, as the specific code is crucial for accurate diagnosis.

-

Interpret DTCs: Use a DTC lookup resource (online databases, scanner built-in tools, repair manuals) to understand the meaning of each DTC. Resources like repairpal.com can be very helpful.

-

Further Diagnosis: OBD2 DTCs provide a starting point. Further diagnostic steps are necessary to pinpoint the root cause of the problem. This might involve visual inspections, component testing, and consulting repair manuals.

-

Clear DTCs (After Repair): Once the issue is resolved, you can use the OBD2 scanner to clear the DTCs. However, ensure the problem is actually fixed; otherwise, the DTCs will likely reappear.

OBD2 Data Logging for DTC Analysis and Vehicle Monitoring

OBD2 data logging can be valuable for in-depth analysis of vehicle behavior, including the conditions under which DTCs are triggered. Tools like the CANedge CAN bus data logger can be configured to record OBD2 data, including DTC-related messages.

By logging OBD2 data, you can:

- Capture DTCs in real-time: Record DTCs as they occur during vehicle operation.

- Analyze Pre-DTC Conditions: Examine sensor data and vehicle parameters leading up to a DTC being set.

- Track Intermittent Faults: Identify patterns and conditions associated with intermittent issues that trigger DTCs sporadically.

- Validate Repairs: After repairs, log data to confirm the issue is resolved and DTCs do not reappear under similar conditions.

Use Cases for OBD2 DTC Data and Vehicle Diagnostics

OBD2 DTC data is essential in various automotive applications:

Car Diagnostics and Repair

OBD2 DTCs are fundamental for diagnosing vehicle problems in repair shops and by DIY mechanics. They guide troubleshooting and help identify faulty components or systems.

Real-time Vehicle Health Monitoring

Streaming OBD2 data, including DTC status, allows for real-time monitoring of vehicle health. This is used in fleet management, telematics, and advanced driver-assistance systems (ADAS).

Predictive Maintenance

Analyzing historical OBD2 DTC data and related parameters can help predict potential component failures, enabling proactive maintenance and reducing downtime.

Vehicle Black Box and Data Logging for Insurance/Warranty

OBD2 loggers can serve as ‘black boxes’ in vehicles, recording DTCs and other data for accident reconstruction, warranty validation, and insurance claims.

Understanding OBD2 DTCs is a vital skill for anyone involved with vehicle maintenance, diagnostics, or automotive data analysis. By learning to retrieve, interpret, and utilize DTC information, you can effectively diagnose vehicle issues, improve repair efficiency, and gain deeper insights into vehicle health and performance.

Looking to log or stream OBD2 data, including DTCs?

Explore OBD2 data logging solutions today!

Explore OBD2 Loggers Contact Us for Solutions

Further Reading

OBD2 DATA LOGGER: EASILY LOG & CONVERT OBD2 DATA

Link to CANEDGE2 product page CANEDGE2 – PRO CAN IoT LOGGER

Link to CANEDGE2 product page CANEDGE2 – PRO CAN IoT LOGGER

[