On-Board Diagnostics (OBD2) systems are integral to modern vehicles, providing a standardized way to access vehicle data for diagnostics and monitoring. At the heart of OBD2 are Parameter IDs, or PIDs. Understanding Obd2 Pids is crucial for anyone involved in vehicle repair, diagnostics, automotive engineering, or even for car enthusiasts wanting to understand their vehicle better.

This guide provides an in-depth overview of OBD2 PIDs, explaining what they are, how they work, and how to use them effectively for vehicle diagnostics. We’ll delve into the structure of OBD2 requests and responses, explore practical examples, and provide a comprehensive OBD2 PID table for quick reference.

Decoding OBD2: Parameter IDs Explained

OBD2 PIDs are codes used to request data from a vehicle’s Engine Control Unit (ECU) and other control modules. Think of them as specific addresses that allow you to ask your car for particular pieces of information, such as engine temperature, vehicle speed, or oxygen sensor readings. These PIDs are standardized by SAE J1979, ensuring a consistent diagnostic approach across different vehicle makes and models.

Using an OBD2 scan tool, interface, or data logger, you can send requests to your vehicle using these PIDs. The vehicle then responds with the requested data, allowing you to monitor vehicle performance, diagnose issues, and gain valuable insights into your car’s operation.

How OBD2 PID Requests and Responses Work

Communication with a vehicle’s OBD2 system happens via the Controller Area Network (CAN) bus. To retrieve data using an OBD2 PID, a specific CAN frame needs to be sent as a request. Let’s break down the process with an example, requesting OBD2 PID ‘0D’ (Vehicle Speed).

OBD2 Request Frame Example (PID 0D – Vehicle Speed):

CAN ID: 7DF

Data Payload: 02 01 0D AA AA AA AA AA- CAN ID (7DF): This is the functional address for OBD2 requests.

- Data Payload:

- 02: Number of bytes following.

- 01: Service $01 – “Show Current Data” (specifies the type of request).

- 0D: The OBD2 PID we are requesting (Vehicle Speed).

- AA AA AA AA AA: Padding bytes (often used but not always necessary).

Upon receiving this request, if the vehicle supports PID 0D, it will send an OBD2 response frame back on the CAN bus.

OBD2 Response Frame Example (PID 0D – Vehicle Speed):

CAN ID: 7E8

Data Payload: 03 41 0D XX AA AA AA AA- CAN ID (7E8): This is the functional address for OBD2 responses (typically 7E8 or higher, depending on the request ID).

- Data Payload:

- 03: Number of bytes following.

- 41: Response code indicating successful PID request (01 + 40 = 41).

- 0D: The PID being responded to (echoes back the requested PID).

- XX: The data bytes containing the vehicle speed in hexadecimal format.

- AA AA AA AA: Padding bytes.

In this example, ‘XX’ represents the hexadecimal value of the vehicle speed. To convert this hexadecimal value into a physical value (like km/h), you need to understand the PID’s scaling, offset, and unit, which are detailed in OBD2 PID documentation and tables like the one provided below.

Alt text: OBD2 PID table overview diagram illustrating Parameter IDs for On-Board Diagnostics, showcasing data parameters for vehicle communication and diagnostics.

Decoding OBD2 PID Data to Physical Values

OBD2 PIDs often return raw data that needs to be converted into meaningful physical values. This conversion typically involves a formula using scale and offset factors. Let’s revisit the example of PID 0C (Engine Speed).

Suppose the OBD2 response data payload for PID 0C is:

04 41 0C 0A 0C AA AA AAHere, 0A 0C (hexadecimal) are the data bytes for Engine Speed.

-

Convert Hexadecimal to Decimal: Convert the hexadecimal value

0A0Cto decimal:

0A0C (hex) = 2572 (decimal) -

Apply Scale and Offset: According to the OBD2 PID table, PID 0C (Engine Speed) has:

- Scale: 0.25

- Offset: 0

Using the formula:

Physical Value = Offset + (Scale * Raw Decimal Value)Engine Speed = 0 + (0.25 * 2572) = 643 RPM

Therefore, the engine speed is 643 revolutions per minute. This process is similar for many OBD2 PIDs that represent sensor readings or calculated values. Understanding these scaling and offset factors is essential for accurately interpreting OBD2 data.

Comprehensive OBD2 PID Table (Service 01)

The following table provides a detailed overview of common OBD2 PIDs for Service 01 (Show Current Data). Service 01 is the most frequently used service for real-time data acquisition in OBD2 diagnostics and data logging.

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

| :——– | :—— | :————————————— | :——– | :——— | :——– | :—– | :——- | :—– |

| 0 | 00 | PIDs supported [01 – 20] | 31 | 32 | 1 | 0 | Encoded | |

| 1 | 01 | Monitor status since DTCs cleared | 31 | 32 | 1 | 0 | Encoded | |

| 2 | 02 | Freeze DTC | 31 | 16 | 1 | 0 | Encoded | |

| 3 | 03 | Fuel system status | 31 | 16 | 1 | 0 | Encoded | |

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 6 | 06 | Short term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 7 | 07 | Long term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 8 | 08 | Short term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 9 | 09 | Long term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 10 | 0A | Fuel pressure (gauge pressure) | 31 | 8 | 3 | 0 | 0 | 765 | kPa |

| 11 | 0B | Intake manifold absolute pressure | 31 | 8 | 1 | 0 | 0 | 255 | kPa |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

| 14 | 0E | Timing advance | 31 | 8 | 0.5 | -64 | -64 | 64 | deg |

| 15 | 0F | Intake air temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 16 | 10 | Mass air flow sensor air flow rate | 31 | 16 | 0.01 | 0 | 0 | 655 | grams/sec |

| 17 | 11 | Throttle position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 18 | 12 | Commanded secondary air status | 31 | 8 | 1 | 0 | Encoded | |

| 19 | 13 | Oxygen sensors present (2 banks) | | | | | | |

| 20 | 14 | Oxygen sensor 1 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| | | Oxygen sensor 1 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 21 | 15 | Oxygen sensor 2 (voltage) | 31 | 8 | 0.005 | 0 | 0 | 1 | volts |

| | | Oxygen sensor 2 (short term fuel trim) | 39 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| … | … | … | … | … | … | … | … | … |

| 124 | 7C | Diesel particulate filter – temperature | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| … | … | … | … | … | … | … | … | … |

| 166 | A6 | Odometer | 31 | 32 | 0.1 | 0 | 0 | 429496730 | km |

| … | … | … | … | … | … | … | … | … |

| 192 | C0 | PIDs supported [C1 – E0] | 31 | 32 | 1 | 0 | Encoded | |

Note: This table is an excerpt. Refer to the full OBD2 PID documentation for a complete list.

This table provides crucial information for each PID, including:

- PID (Decimal/Hexadecimal): The Parameter ID in both decimal and hexadecimal formats.

- Name: A description of the parameter.

- Bit Start & Bit Length: Defines where the data for this PID starts and how many bits it occupies within the response frame.

- Scale & Offset: Factors used to convert the raw data to physical values.

- Min/Max: The valid range of values for the parameter.

- Unit: The unit of measurement for the physical value.

Understanding these parameters allows you to programmatically decode OBD2 data using tools and software.

Programmatic OBD2 PID Formats: DBC and CSV

For advanced users and developers, OBD2 PIDs are often utilized in programmatic environments. Two common formats for representing OBD2 PID information for software are DBC and CSV.

-

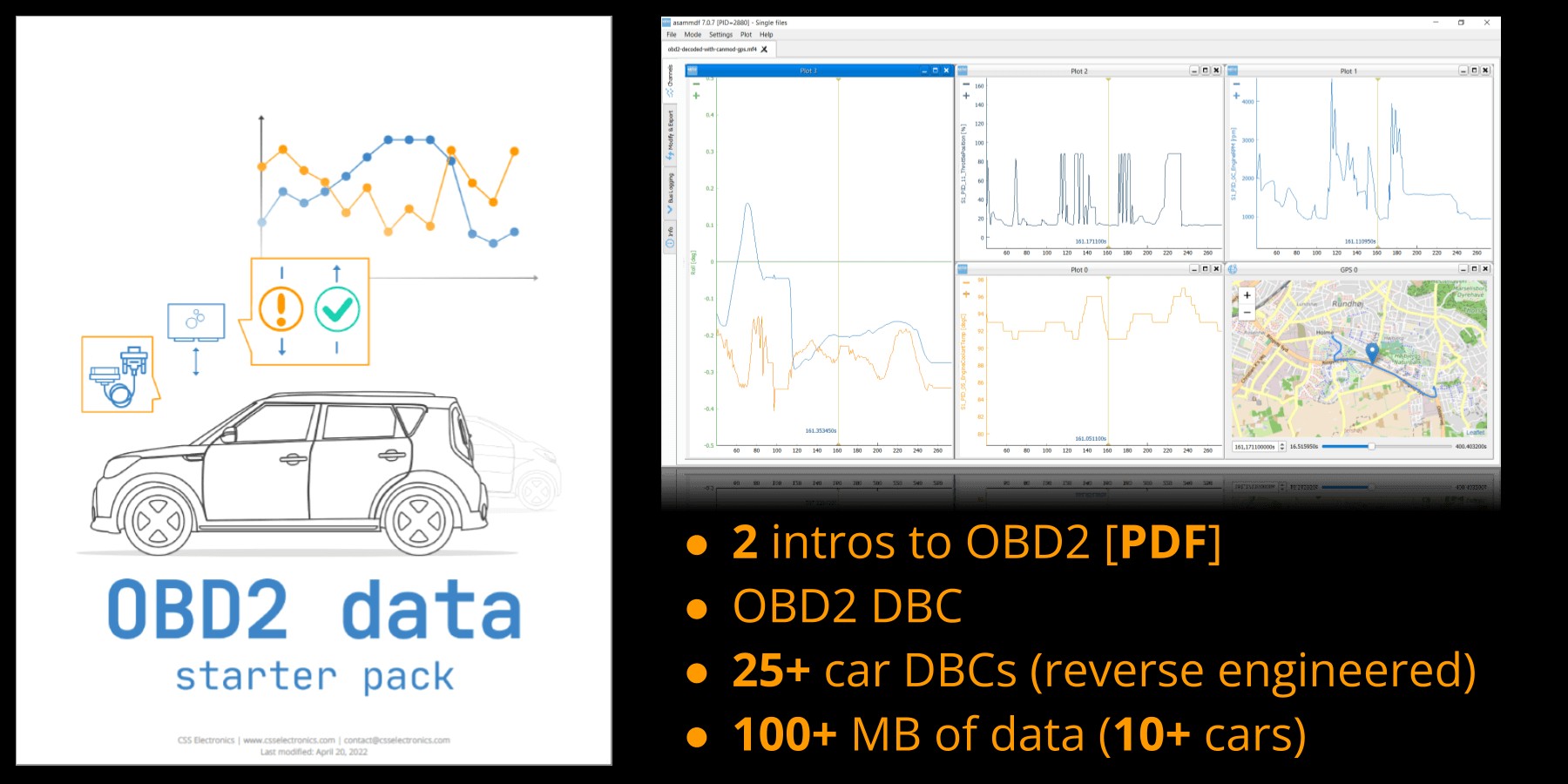

DBC (CAN Database) Files: DBC files are primarily used in CAN bus analysis and simulation tools. An OBD2 DBC file contains a structured description of OBD2 PIDs, CAN IDs, data types, scaling, and offsets. This allows software tools to automatically decode raw CAN data containing OBD2 responses into human-readable signals. DBC files are invaluable when working with OBD2 data loggers, interfaces, and analysis software.

DBC

-

CSV (Comma Separated Values) Files: CSV files offer a simpler, text-based format to store OBD2 PID information. An OBD2 CSV file typically includes columns for PID, name, scale, offset, units, and other relevant parameters. CSV files are easily parsed by scripting languages like Python or used in spreadsheet software. They are useful for developing custom OBD2 decoding scripts or for data analysis tasks.

These programmatic formats streamline the process of working with OBD2 data, especially when dealing with large datasets from data loggers or when integrating OBD2 data into custom applications. You can even find sample OBD2 data in formats like MF4, which can be analyzed using tools like asammdf GUI.

J1939 data pack

J1939 data pack

Practical Applications of OBD2 PIDs

OBD2 PIDs are not just theoretical concepts; they have numerous practical applications across various fields:

- Vehicle Diagnostics and Repair: Mechanics and technicians use OBD2 scan tools to read Diagnostic Trouble Codes (DTCs) and monitor live data via PIDs to diagnose vehicle issues accurately. Understanding PIDs allows for deeper diagnostics beyond basic error codes.

- Performance Monitoring and Tuning: Car enthusiasts and performance tuners utilize OBD2 PIDs to monitor engine performance parameters in real-time. This data helps in optimizing engine tuning, tracking performance improvements, and identifying potential issues early on.

- Fleet Management and Telematics: OBD2 data, accessed through PIDs, is crucial for fleet management systems. Telematics devices use OBD2 to gather data like vehicle speed, engine load, fuel consumption, and more, enabling efficient fleet tracking, driver behavior monitoring, and predictive maintenance.

- Automotive Research and Development: Engineers and researchers in the automotive industry rely on OBD2 PIDs for data acquisition during vehicle testing and development. This data is used to analyze vehicle performance, validate new technologies, and improve vehicle designs.

- DIY Car Enthusiasts and Hobbyists: For individuals passionate about cars, OBD2 PIDs offer a window into their vehicle’s inner workings. With affordable OBD2 interfaces and software, hobbyists can monitor their car’s health, track fuel efficiency, and even create custom dashboards for vehicle data visualization.

software tools

Conclusion: Mastering OBD2 PIDs for Vehicle Understanding

OBD2 PIDs are the key to unlocking a wealth of information from your vehicle’s diagnostic system. Whether you are a professional mechanic, an automotive engineer, or a car enthusiast, understanding OBD2 PIDs empowers you to diagnose issues, monitor performance, and gain deeper insights into vehicle operation.

By understanding how OBD2 requests and responses are structured, how to decode PID data, and utilizing resources like OBD2 PID tables and programmatic formats, you can effectively leverage OBD2 PIDs for a wide range of applications. Explore the provided resources, experiment with OBD2 tools, and start harnessing the power of OBD2 PIDs to better understand your vehicle today.

For those interested in further exploration, consider downloading our OBD2 data pack for hands-on experience with real OBD2 data and DBC files. And if you have specific OBD2 data logging needs or questions, don’t hesitate to contact us for expert support.