As a car owner or fleet manager, understanding your vehicle’s health is paramount. Modern vehicles are equipped with sophisticated onboard computer systems that monitor a multitude of functions. When something goes wrong, these systems generate Diagnostic Trouble Codes (DTCs) to alert you to potential issues. Specifically, DTC codes OBD2 are standardized codes used across a vast majority of vehicles, providing a crucial first step in diagnosing automotive problems.

This article will delve into the world of DTC codes OBD2, explaining what they are, how to interpret them, and why understanding them is essential for vehicle maintenance and repair. Whether you’re a seasoned mechanic or a car owner trying to decipher that pesky check engine light, this guide will equip you with the knowledge to navigate DTC codes OBD2 effectively.

Understanding DTC Codes and OBD-II Systems

Diagnostic Trouble Codes (DTCs) are essentially error messages generated by your vehicle’s On-Board Diagnostics system. The OBD system monitors various components and systems within your car, from the engine and transmission to emissions control and braking systems. When the OBD system detects a problem outside of normal operating parameters, it generates a DTC and often illuminates the check engine light (also known as the malfunction indicator lamp or MIL) on your dashboard.

OBD-II is the second generation of on-board diagnostics and has been mandatory for all cars and light trucks sold in the United States since 1996. This standardization means that regardless of the make or model of your vehicle (post-1996), the basic diagnostic codes and the way you access them are generally the same. For heavier vehicles, especially in commercial fleets, the J1939 standard is often used in conjunction with or instead of OBD-II, but OBD-II remains the dominant system for light and medium-duty vehicles.

To access DTC codes OBD2, you’ll typically use an OBD-II scanner. This handheld device plugs into a standardized diagnostic port, usually located under the dashboard on the driver’s side. Once connected, the scanner can read the stored DTCs and provide valuable information about the nature of the problem.

OBD2 Scanner Port Location

OBD2 Scanner Port Location

Decoding OBD-II DTCs: A Character-by-Character Guide

DTC codes OBD2 are not random strings of characters. They follow a structured five-character format, where each position provides specific information about the fault. Understanding this structure is key to interpreting the codes and pinpointing the potential issue.

Let’s break down each character of a typical OBD-II DTC:

First Character: The System Designation

The first character of a DTC code OBD2 is always a letter, indicating the primary system affected:

- P (Powertrain): This is the most common category and signifies issues related to the engine, transmission, fuel system, and associated components.

- C (Chassis): “C” codes refer to problems with chassis systems like the brakes, steering, suspension, and anti-lock braking system (ABS).

- B (Body): “B” codes indicate issues within the vehicle’s body systems, including power windows, airbags, central locking, and comfort/convenience features located in the passenger compartment.

- U (Network/Communication): “U” codes point to communication problems within the vehicle’s computer network. These can be complex issues involving the various electronic control units (ECUs) and their communication buses.

Second Character: Code Type

The second character of a DTC code OBD2 is a number that defines the code’s standardization:

- 0 (Generic/SAE): A “0” indicates a generic OBD-II code, standardized by the Society of Automotive Engineers (SAE). These codes are common across all OBD-II compliant vehicles, regardless of manufacturer.

- 1 (Manufacturer-Specific/Enhanced): A “1” signifies a manufacturer-specific or enhanced code. These codes are defined by the vehicle manufacturer and are specific to their makes and models. If you encounter a code starting with “1,” consulting the vehicle’s service manual or a dealership-specific diagnostic tool may be necessary for accurate interpretation.

Third Character: Subsystem Designation

The third character of a DTC code OBD2 (when the second character is “0”, indicating a generic code) further categorizes the problem within the designated system. This character is a number from 0 to 7:

- 0: Emission Management System

- 1: Fuel and Air Metering

- 2: Fuel and Air Metering – Injector Circuit

- 3: Ignition System or Misfire

- 4: Auxiliary Emission Controls

- 5: Vehicle Speed Controls & Idle Control System

- 6: Computer Output Circuit

- 7 & 8: Transmission (for Powertrain “P” codes)

Fourth and Fifth Characters: Specific Fault Index

The fourth and fifth characters of a DTC code OBD2 are numeric digits (00-99) that provide the most specific information about the fault. This “Specific Fault Index” pinpoints the exact component or circuit malfunctioning within the subsystem identified by the preceding characters. For example, within the “Fuel and Air Metering” subsystem (third character ‘1’), code P0101 might indicate a Mass Air Flow (MAF) sensor performance issue, while P0171 might indicate a lean fuel mixture condition.

Example: Decoding P0420

Let’s revisit the example DTC code P0420 and apply our understanding:

- P: Powertrain (problem in the engine or related systems)

- 0: Generic OBD-II code (standardized for all vehicles)

- 4: Auxiliary Emission Controls (problem in the emission control system)

- 20: Specific Fault Index (catalyst system efficiency below threshold)

Therefore, P0420 indicates a problem with the catalytic converter’s efficiency – a common issue that needs attention to ensure emissions compliance and optimal vehicle performance.

OBD2 Scanner Port Location

OBD2 Scanner Port Location

J1939 DTCs for Heavy-Duty Vehicles

While DTC codes OBD2 are prevalent in light and medium-duty vehicles, heavy-duty vehicles, such as semi-trucks, buses, and construction equipment, often utilize the J1939 standard for diagnostics. J1939 codes are structured differently but serve the same purpose: to identify and report vehicle malfunctions.

A J1939 DTC typically consists of four key fields:

- Suspect Parameter Number (SPN): This is a numerical code assigned by SAE to a specific component or subsystem. The SPN essentially identifies what is malfunctioning (e.g., a specific sensor, valve, or module).

- Failure Mode Identifier (FMI): The FMI is a code indicating how the component is failing. Examples include “no signal,” “signal out of range,” “short circuit to ground,” or “data erratic.”

- Occurrence Counter (OC): This field tracks how many times the fault has occurred. An increasing OC can indicate an intermittent problem becoming more frequent.

- Conversion Method (CM): Primarily for older systems, CM specifies data handling within the DTC message.

Interpreting J1939 codes usually requires specialized diagnostic tools and access to J1939 documentation. However, understanding the basic fields helps in grasping the nature of the reported fault.

Clearing DTC Codes: Proceed with Caution

Once you’ve diagnosed and addressed the issue indicated by a DTC code OBD2, you may want to clear the code and turn off the check engine light. Most OBD-II scanners have a “clear codes” function. However, it’s crucial to understand when and how to clear DTCs responsibly.

When to Clear DTC Codes:

- After Confirmed Repair: Only clear DTC codes after you have properly diagnosed and repaired the underlying problem. Clearing codes without fixing the issue will only temporarily turn off the check engine light, and the code will likely reappear.

- For Diagnostic Purposes: In some diagnostic scenarios, clearing a code and then re-testing can help determine if a problem is still present or if it was a one-time occurrence.

When NOT to Clear DTC Codes:

- Before Diagnosis: Do not clear DTC codes before properly diagnosing the problem. Erasing the codes removes valuable information that can guide the diagnostic process.

- As a Substitute for Repair: Clearing codes is not a fix. Ignoring the underlying issue can lead to further damage, safety risks, and more costly repairs down the line.

- Permanent DTCs: Some issues trigger “permanent DTCs” that cannot be cleared with a scanner or by disconnecting the battery. These codes will only clear themselves after the vehicle’s system confirms the problem is resolved through multiple drive cycles.

Using a Code Reader to Clear Codes:

- Connect your OBD-II scanner to the diagnostic port.

- Turn the ignition to the “ON” position (engine off).

- Navigate to the “Read Codes” or “Scan” function to view the stored DTCs.

- Once you’ve noted the codes and addressed the problem, navigate to the “Clear Codes” or “Erase Codes” function on your scanner.

- Confirm the clearing process as prompted by your scanner.

- Start the engine and check if the check engine light remains off.

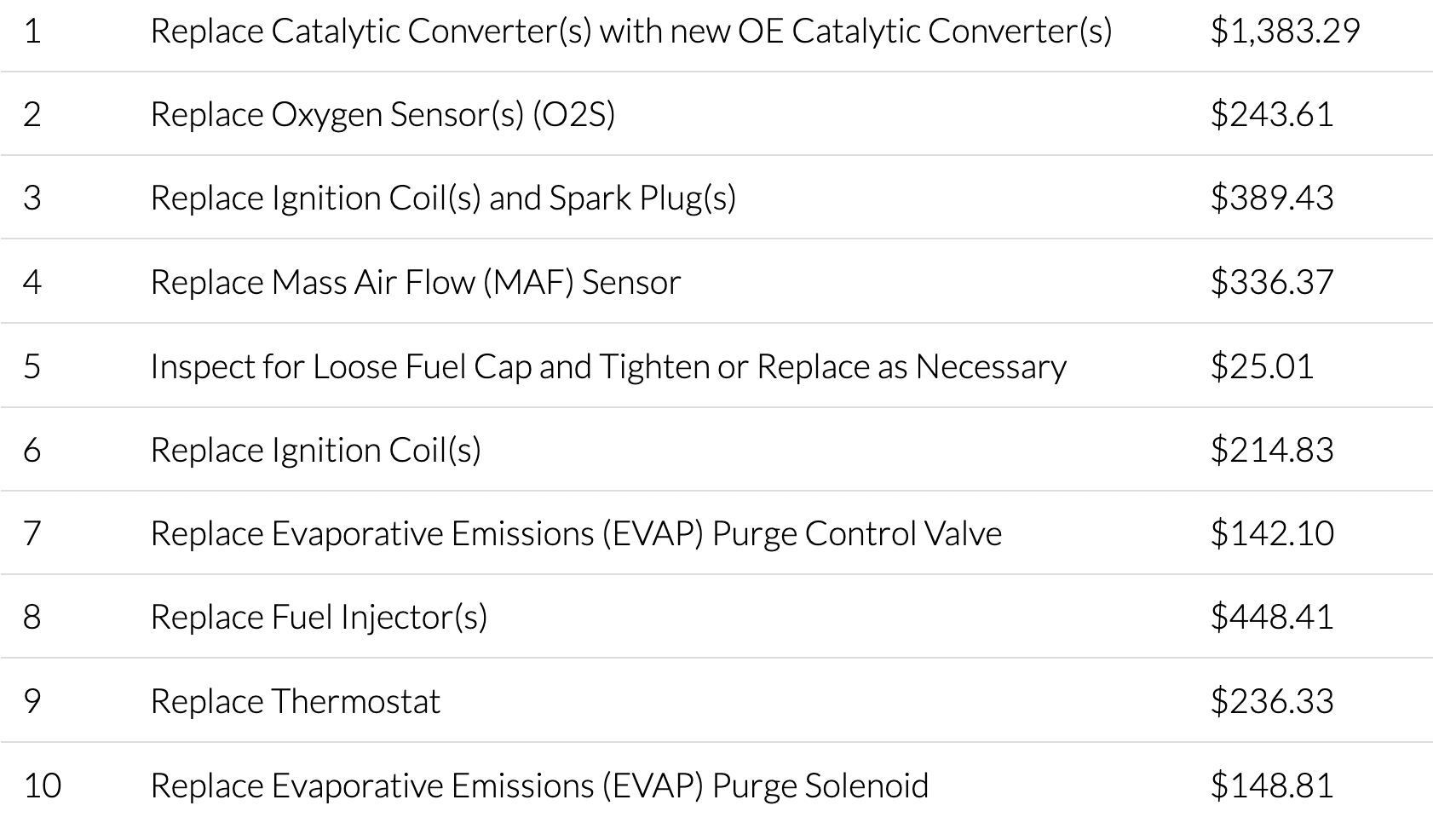

Common Check Engine Repairs

Common Check Engine Repairs

Managing DTC Codes for Fleets with Telematics

For fleet managers overseeing multiple vehicles, manually scanning for DTC codes OBD2 on each vehicle can be time-consuming and inefficient. Telematics systems offer a powerful solution for remote DTC monitoring and fleet maintenance management.

Telematics devices, when integrated with vehicles, can:

- Real-time DTC Alerts: Instantly notify fleet managers when a vehicle generates a DTC. These alerts include the specific code and often a description, allowing for immediate assessment of the issue.

- Remote Diagnostics: In some advanced systems, telematics can provide more detailed diagnostic data beyond just the DTC, potentially including freeze frame data and sensor readings.

- Automated Maintenance Scheduling: By tracking mileage, engine hours, and DTC occurrences, telematics systems can automate preventative maintenance schedules, helping to address potential issues before they escalate into major problems.

- DTC Reporting and Trend Analysis: Telematics platforms can generate reports on DTC trends across the fleet. This data can identify common issues, potential component failures, and areas for improved maintenance practices.

By leveraging telematics for DTC codes OBD2 management, fleet operators can proactively address vehicle issues, minimize downtime, improve vehicle reliability, and ultimately reduce maintenance costs.

Telematics for Fleet Management

Telematics for Fleet Management

Telematics for Insurance Cost Control

Telematics for Insurance Cost Control

Conclusion: Empowering Vehicle Diagnostics with DTC Codes OBD2

Understanding DTC codes OBD2 is a valuable skill for anyone involved with vehicle maintenance, from individual car owners to large fleet operators. These standardized codes provide a crucial starting point for diagnosing automotive problems, enabling timely repairs and preventing more significant issues.

By learning to interpret DTC codes OBD2, you can communicate more effectively with mechanics, make informed decisions about vehicle repairs, and leverage the power of on-board diagnostics to keep your vehicles running smoothly and efficiently. For fleet management, telematics systems take DTC monitoring to the next level, providing remote access, automated alerts, and data-driven insights to optimize fleet maintenance and minimize downtime. Embracing the knowledge of DTC codes OBD2 empowers you to take a proactive approach to vehicle health and maintenance.