Modern vehicles are technological marvels, boasting significantly more control units than cars from the 1990s. This advancement means that diagnosing car problems has become more accessible than ever, often starting with simply reading error codes. This is where OBD2 scanners become indispensable tools for car owners.

Learning how to use an OBD2 scanner can save you considerable time and money on car repairs. This guide provides you with everything a typical driver needs to understand about these devices and how to effectively use them.

Understanding the Function of an OBD2 Scanner

An OBD2 scanner is a diagnostic device that connects to a specific port in your car to gather data from its control units. This data includes crucial fault codes and real-time information such as pressure, temperature, and speed readings.

An OBD2 scanner being used for car diagnostics

An OBD2 scanner being used for car diagnostics

This wealth of information originates from various sensors throughout your vehicle. Typically, fault codes are triggered when a sensor reading falls outside of the acceptable range or when a sensor stops responding altogether.

More sophisticated diagnostic scanners offer advanced capabilities, including performing service functions and even coding. Coding is particularly essential when replacing certain components in contemporary vehicles, ensuring the new parts communicate correctly with the car’s computer system.

On-board diagnostics (OBD2) systems have been a standard feature in all cars manufactured since 1996 in the United States and since 2004 in Europe, making OBD2 scanners universally applicable to modern vehicles.

Exploring Different Types of OBD2 Scanners

The market offers a wide array of OBD2 scanners to suit various needs and budgets.

Bluetooth OBD2 Code Readers: These are the most basic and affordable type. They pair with your smartphone via Bluetooth and are incredibly user-friendly. Typically costing just a small amount, these readers can access fault codes and basic live data, making them a practical choice for everyday drivers seeking to understand the cause of a check engine light.

Dedicated OBD2 Scanners: For those who prefer a more hands-on approach to car maintenance and DIY repairs, dedicated OBD2 scanners offer enhanced functionality. These devices can reset service lights, activate service functions necessary for tasks like brake pad replacement, and provide access to a broader range of live data. Ranging from around $100 upwards, these scanners offer a balance of capability and affordability for car enthusiasts and DIYers.

Professional OBD2 Diagnostic Tools: Automotive professionals require tools that can handle any diagnostic scenario, from routine maintenance to complex engine repairs. Professional-grade OBD2 diagnostic tools go far beyond simply reading fault codes and live data. They offer extensive coding and programming capabilities, allowing for deep-level system adjustments and component programming. While these tools can cost thousands of dollars and require specialized knowledge, they are essential for professional automotive electricians and mechanics.

Step-by-Step Guide: How to Read OBD2 Fault Codes

Reading fault codes is the foundational skill in OBD2 diagnostics. If you intend to use an OBD2 scanner, understanding this process is crucial. While the controls may differ slightly between scanner models, the fundamental procedure remains consistent.

Step 1: Establish a Connection

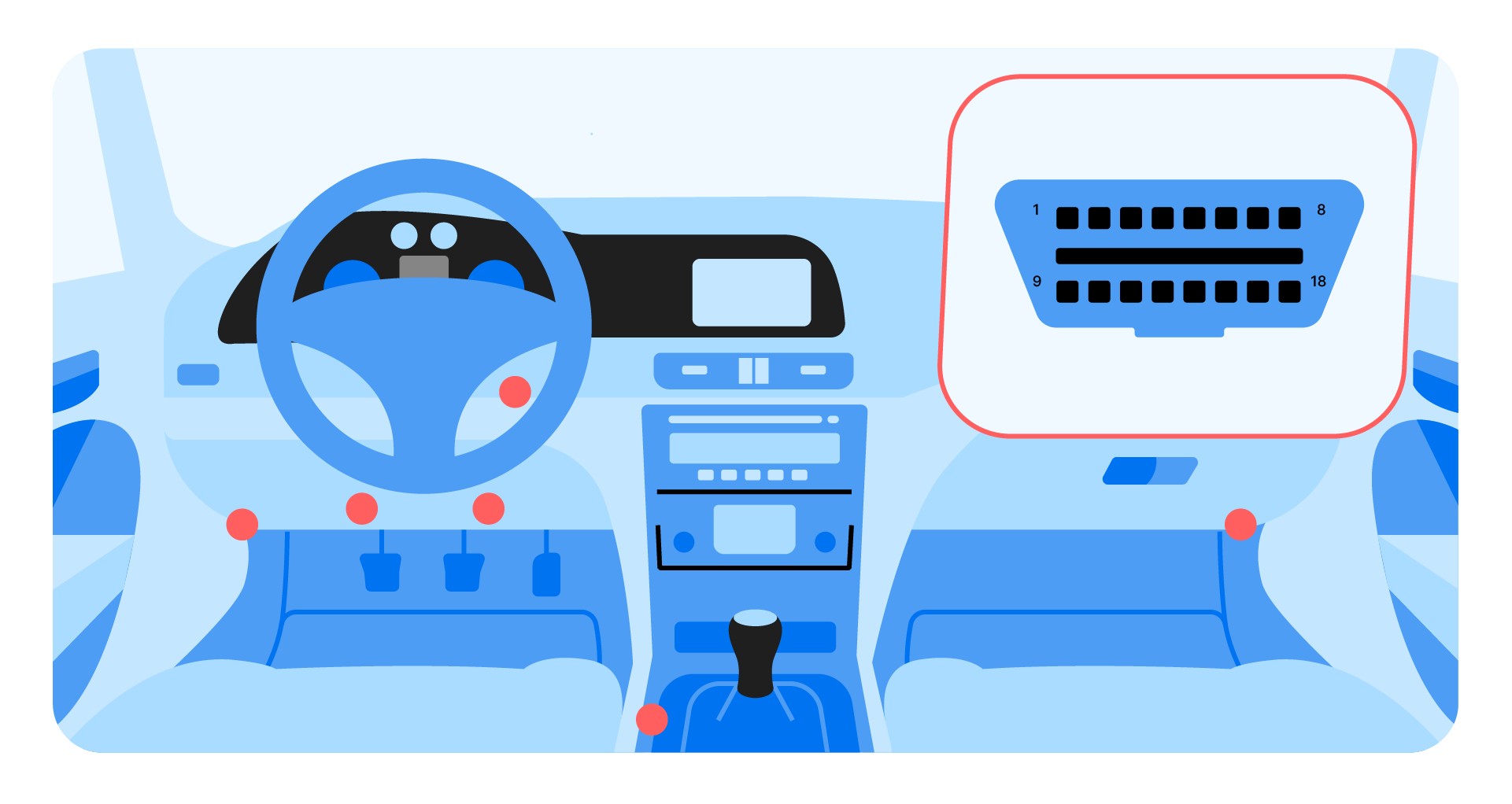

Every modern car is equipped with an OBD2 port. This port is usually located beneath the steering wheel or within the center console area. It may be concealed by a small plastic cover. Locate the port and securely plug in your OBD2 scanner.

Location of a car's OBD2 scanner port under the steering wheel

Location of a car's OBD2 scanner port under the steering wheel

Many contemporary scanners use Bluetooth for wireless connectivity. If you are using a Bluetooth scanner, ensure it is properly paired with your device.

Step 2: Turn on the Ignition

Computer diagnostics require the car’s ignition to be turned on. Before proceeding with the scan, turn the ignition to the “ON” position. To minimize electrical load, switch off unnecessary accessories like headlights, radio, and air conditioning.

While most vehicles allow fault code scanning with the engine running, fault codes are stored in the vehicle’s computer memory and will persist until manually cleared. Starting the engine can be beneficial when analyzing live data, as it provides a broader range of sensor readings.

Step 3: Vehicle Identification

Once the OBD2 scanner is connected and the ignition is on, you will need to identify your vehicle to the scanner. This typically involves selecting the car’s make, model, and year. This information is essential for the scanner to accurately recognize the vehicle’s control units and interpret the data correctly.

Many advanced diagnostic tools feature an automatic VIN recognition system. This system automatically detects the vehicle identification number (VIN) and configures the necessary settings. You also usually have the option to manually enter the VIN if the automatic recognition fails.

Step 4: Initiate Fault Code Scan

Navigate the scanner’s menu to find and select the fault code reading or scanning option. Most scanners offer choices to scan specific control units or perform a comprehensive scan of all available units.

If you are unsure how to locate these options, consult the scanner’s built-in help section or user manual for guidance.

The duration of a full system scan varies depending on the car model and the number of control units, typically ranging from a few seconds to several minutes.

Step 5: Interpret Fault Codes

The fault codes displayed after the scan are the key indicators of potential issues, often triggering warning lights on your dashboard. Some fault codes are straightforward, such as “C0031 – Front Left Wheel Speed Sensor Circuit”. This code directly suggests a problem with the front left wheel speed sensor.

However, fault codes can sometimes point to more complex underlying issues. For instance, a code like “P0300 – Random/Multiple Cylinder Misfire Detected” indicates engine misfires, but the root cause could be anything from spark plug issues to fuel delivery problems or vacuum leaks.

Utilizing Live Data for Enhanced Diagnostics

Beyond fault codes, the ability to read live data significantly enhances diagnostic capabilities. Most control units provide a live data section, allowing you to monitor real-time sensor readings. How is this beneficial?

Imagine a scenario where your car is experiencing reduced power, and the only fault code is related to limp mode activation. By examining live data, you can assess critical parameters like fuel pressure, boost pressure (if applicable), intake airflow, and intake manifold pressure to identify any anomalies.

An OBD2 scanner displaying live data readings

An OBD2 scanner displaying live data readings

While OBD2 scanners offer powerful diagnostic features, interpreting fault codes and pinpointing the exact cause of a problem can sometimes require further expertise and troubleshooting.

OBD2 Scanners: A Vital Tool for Used Car Inspections

The used car market can present challenges for buyers. Unscrupulous sellers may attempt to sell vehicles with hidden issues, ranging from mechanical faults to electrical problems or even legal encumbrances.

While vehicle history reports provide valuable background information, a thorough pre-purchase inspection is crucial to avoid unexpected repair costs.

Before buying a used car, always obtain a vehicle history report and use an OBD2 scanner to check for fault codes. If you are unfamiliar with using a scanner or interpreting the results, it is advisable to take the car to a professional mechanic for a comprehensive inspection.

Verify Your VIN for Vehicle History

Protect yourself from potential problems by checking a vehicle’s history. Get an instant report to uncover crucial information.

Clearing Fault Codes: When and How

Scanning for fault codes is a diagnostic step, and fault codes themselves do not always directly reveal the source of a problem. Even if a scan indicates a faulty mass airflow sensor, experienced technicians often use a multimeter to test the sensor and confirm the diagnosis before replacing parts. Fault codes can sometimes be triggered by issues like damaged wiring, loose connections, or corrosion, rather than a faulty sensor itself.

After addressing the identified issue, it’s essential to re-scan for fault codes. If the code no longer appears, the problem is likely resolved. Most OBD2 scanners offer a function to clear fault codes from the vehicle’s computer memory. However, it’s crucial to only clear codes after the underlying issue has been properly diagnosed and repaired. Clearing codes without fixing the problem will only temporarily remove the warning light, and the issue will likely reappear.

Frequently Asked Questions

This section could be expanded with common questions about OBD2 scanners and their usage to further enhance the article’s helpfulness and SEO value, but as per instructions I will leave it as is.

Evaldas Zabitis, Automotive Content Creator

Evaldas Zabitis, Automotive Content Creator

Article by

Evaldas Zabitis

Evaldas has been writing about cars since middle school, fueled by a lifelong passion for automobiles. His hands-on experience began right after acquiring his driver’s license, investing his savings in older cars to learn through repairing, driving, and selling them. Evaldas maintains a keen interest in automotive technological advancements and actively participates in discussions within the automotive community.