Owning a 1996 Nissan 300ZX presents a unique set of circumstances for car enthusiasts, particularly when it comes to modifications and tuning, due to its OBD-II system. While OBD-II is now a standard and beneficial tool in modern vehicle diagnostics and tuning, the 1996 300ZX, or Z32, occupies an unusual position. This model year was the first to implement OBD-II in North America, coinciding with the final year of 300ZX production for the North American market. This timing has unfortunately positioned the 1996 300ZX as somewhat of an outlier compared to earlier Z32 models when considering performance enhancements.

One of the key differences lies in engine performance. The 1996 300ZX models experienced a reduction of 20 horsepower compared to previous years. This decrease is attributed to less aggressive camshaft profiles for both manual transmission (MT) and automatic transmission (AT) versions. To illustrate, 1990-1995 MT models boasted a 248-degree duration on both intake and exhaust camshafts, while AT models from the same period had 240-degree intake and 248-degree exhaust camshafts. In stark contrast, the 1996 models utilized a 232-degree intake and 240-degree exhaust setup. Furthermore, the 1996 models also feature reduced valve lift and lack Nissan’s Variable Cam Timing (VTC) system, further impacting overall power output across the RPM range.

Adding to the complexity, the 1996 300ZX is equipped with a specific OBD-II ECU that presents challenges for tuning and is more prone to triggering diagnostic trouble codes (DTCs) when non-emission-compliant modifications are installed. Some owners have explored retrofitting pre-1996 specifications, involving changes to wiring, ECU, and camshaft configurations. While this might be a viable route for some, it poses significant hurdles, especially in regions with stringent emissions regulations like California.

However, challenges are often met with ingenuity and determination. Enter Alex, a long-term customer with a 1996 300ZX Twin Turbo (TT) who was eager to enhance his car’s performance. Having been a customer for a decade, Alex gradually upgraded his Z over the years. Recently, he aimed for a more substantial power increase, opting for a series of performance modifications. These included 3″ 4-Bolt Downpipes designed for stock turbos, 3″ to 2.5″ Test Pipes, Ash 2.5″ Intercooler (I/C) Piping with Specialty Z Outlet Pipes and Massives, Selin Dual POP intake, Nismo 740cc Injectors, Z1 Throttle Bodies, a J-Spec front bumper, and cooling upgrades suitable for track use in autocross and road course events.

Freshly painted J-Spec bumper and Powertrix Carbon Fiber Ducts on a 1996 Nissan 300ZX.

Freshly painted J-Spec bumper and Powertrix Carbon Fiber Ducts on a 1996 Nissan 300ZX.

Ash intercooler piping and components installed on a 1996 Nissan 300ZX engine.

Ash intercooler piping and components installed on a 1996 Nissan 300ZX engine.

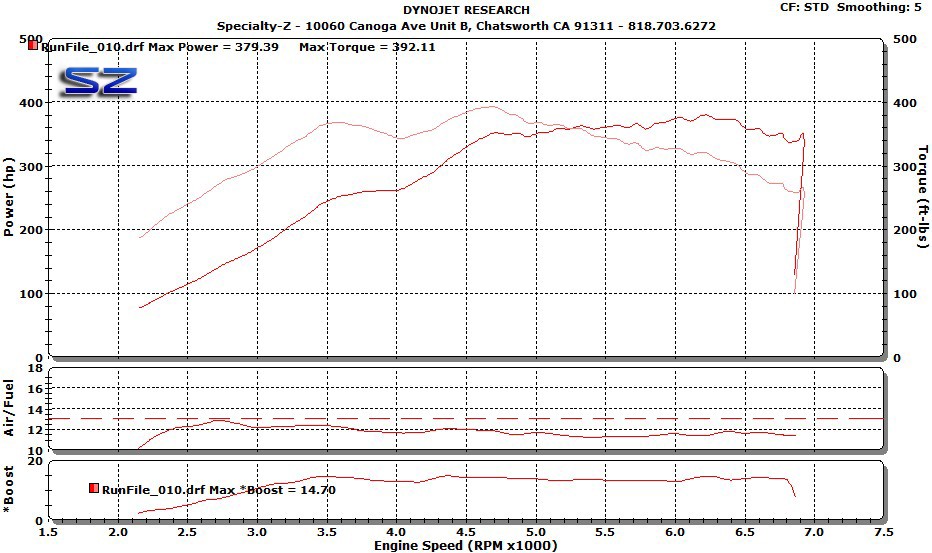

The dyno results obtained on 91 octane fuel highlighted the limitations imposed by the 1996 OBD-II system. Due to the ECU constraints, an Apexi Fuel Controller (AFC) was used for fuel tuning adjustments.

1996 Nissan 300ZX on a dynamometer during performance tuning.

1996 Nissan 300ZX on a dynamometer during performance tuning.

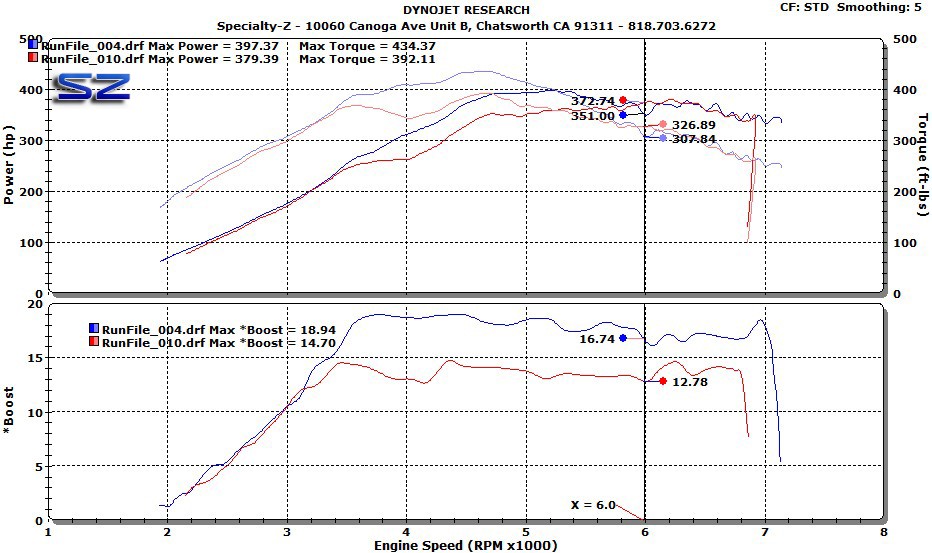

The subsequent dyno testing revealed the inherent restrictions of modifying a 1996 300ZX TT. Despite increasing boost levels and utilizing 100 octane fuel, significant power gains were not realized beyond a certain RPM range. The dyno graph comparison between 91 octane at 14.7 psi and 100 octane at nearly 19 psi illustrates this point. While initial gains were observed up to approximately 5800 RPM, the engine’s efficiency diminished beyond this point, failing to effectively utilize the increased boost. Pushing the engine further under these conditions would only induce unnecessary stress.

Dyno graph showing horsepower and torque comparison between 91 and 100 octane fuel for a modified 1996 Nissan 300ZX, highlighting OBD-II limitations.

Dyno graph showing horsepower and torque comparison between 91 and 100 octane fuel for a modified 1996 Nissan 300ZX, highlighting OBD-II limitations.

Remarkably, at 12 psi boost on 91 octane, the engine demonstrated greater efficiency, producing 20 more horsepower and torque compared to the 100 octane run at higher boost levels past 5800 RPM. This underscores the challenge in maximizing performance from a 1996 300zx Obd2 system with conventional tuning methods at higher RPMs. To effectively leverage higher octane fuel in the 1996 Z, it would necessitate limiting boost pressure beyond 5800 RPM to maintain engine efficiency.

Looking ahead, Alex’s 1996 300ZX project aims to address these limitations by incorporating pre-1996 camshafts and integrating Nissan’s VTC system. Intriguingly, this is planned to be achieved without ECU or wiring harness modifications, utilizing innovative solutions to maintain California emissions compliance, further demonstrating that even with the quirks of the 1996 300ZX OBD2 system, performance enhancements are still within reach.