The 2003 Mercedes Sl500 is renowned for its sporty performance and luxurious features, and a key component contributing to its unique driving experience is the Active Body Control (ABC) suspension system. This sophisticated hydraulic system offers superior handling and ride comfort. However, like any complex automotive technology, the ABC suspension can encounter issues over time. In this article, we delve into a recent case at Pawlik Automotive in Vancouver, where a 2003 Mercedes SL500 presented with a frustrating suspension problem: it kept dropping, particularly in the front. Let’s explore the diagnostic journey and the solution to restore this SL500’s smooth ride and level stance.

Understanding the Mercedes-Benz ABC Suspension System

Unlike traditional spring and shock absorber setups or even air suspension, the ABC system in the 2003 Mercedes SL500 is a fully active hydraulic system. Bernie Pawlik from Pawlik Automotive, an expert in Mercedes-Benz vehicles, explains, “It’s a pretty awesome system. The car always sits level. You can raise it a little bit if you need extra ground clearance.” The magic of ABC lies in its ability to virtually eliminate body roll during cornering and prevent nose-dive under braking, providing a remarkably smooth and controlled driving experience. This is achieved through a high-pressure hydraulic pump, intricate metal lines, valve blocks at each wheel, hydraulic struts, accumulators, and a network of sensors. It’s a far cry from “a couple shocks in each corner,” as Bernie aptly puts it, highlighting the system’s complexity.

The Case of the Dropping SL500: Initial Symptoms

The owner of this 2003 Mercedes SL500 brought the vehicle to Pawlik Automotive with concerns about the suspension. The primary symptom was that the car would noticeably drop, especially in the front, often overnight. As Bernie describes, “sometimes overnight the customer would leave it and he’d find the vehicle especially on the front, the car would be down.” This not only affected the car’s appearance but also raised concerns about potential damage, as the fenders could rest on the tires if the wheels weren’t perfectly straight when parked – a crucial tip mentioned even in the owner’s manual for ABC-equipped Mercedes.

The initial visual inspection confirmed the issue. When functioning correctly, the 2003 Mercedes SL500 sits level, with a balanced gap between the top of the tires and the wheel wells.

2003 Mercedes Benz SL500 showcasing level ABC suspension

2003 Mercedes Benz SL500 showcasing level ABC suspension

A 2003 Mercedes Benz SL500 with properly functioning ABC suspension, showing even ride height and wheel well gap.

However, in this case, one side of the front end would sag significantly, creating an uneven stance. This pointed towards a leak or pressure loss within the ABC system.

Round One: Strut and Accumulator Replacement

Interestingly, this wasn’t the first time Pawlik Automotive had addressed suspension issues on this particular SL500. As a new client, the owner had initially brought the car in for various maintenance items, and suspension concerns were already on the radar. The first round of diagnostics revealed a leaking right front strut. Replacing this strut was the initial step in addressing the suspension drop.

Following the strut replacement, Bernie personally tested the vehicle and noticed another issue. “If you go over like some speed bumps pretty hard, there’s a red warning light that would come on, you could feel the car kind of knocking and bumping.” This symptom, combined with a low system pressure code, despite a functioning hydraulic pump, led to the diagnosis of faulty accumulators.

Accumulators are vital components in the ABC system. They act as pressure reservoirs, using diaphragms to store and quickly release hydraulic pressure, allowing for near-instantaneous suspension adjustments. Replacing the accumulators seemed to resolve the immediate pressure issues and warning lights. After overnight testing, the car appeared to hold its ride height, and the vehicle was returned to the customer.

The Persistent Problem: Valve Block Suspect

Unfortunately, the relief was short-lived. After a day or two, the SL500 was back with the same dropping issue, particularly at the left front corner, accompanied by a red warning light. This indicated that while the strut and accumulators were addressed, the root cause of the overnight pressure loss remained. Rediagnosis pointed towards the suspension valve blocks as the next likely culprit.

Bernie explains the function of these valve blocks: “These are very large solenoids… They’re valves that you know, they have seats and they hold pressure. There’s a lot of pressure in the system, so they have to hold that pressure. So if there’s a slightest bit of leakage, the car will start to drop.” Given the age of the 2003 Mercedes SL500, nearly two decades, component wear and tear, especially in a high-pressure hydraulic system, becomes a significant factor.

Valve Block Replacement: The Solution

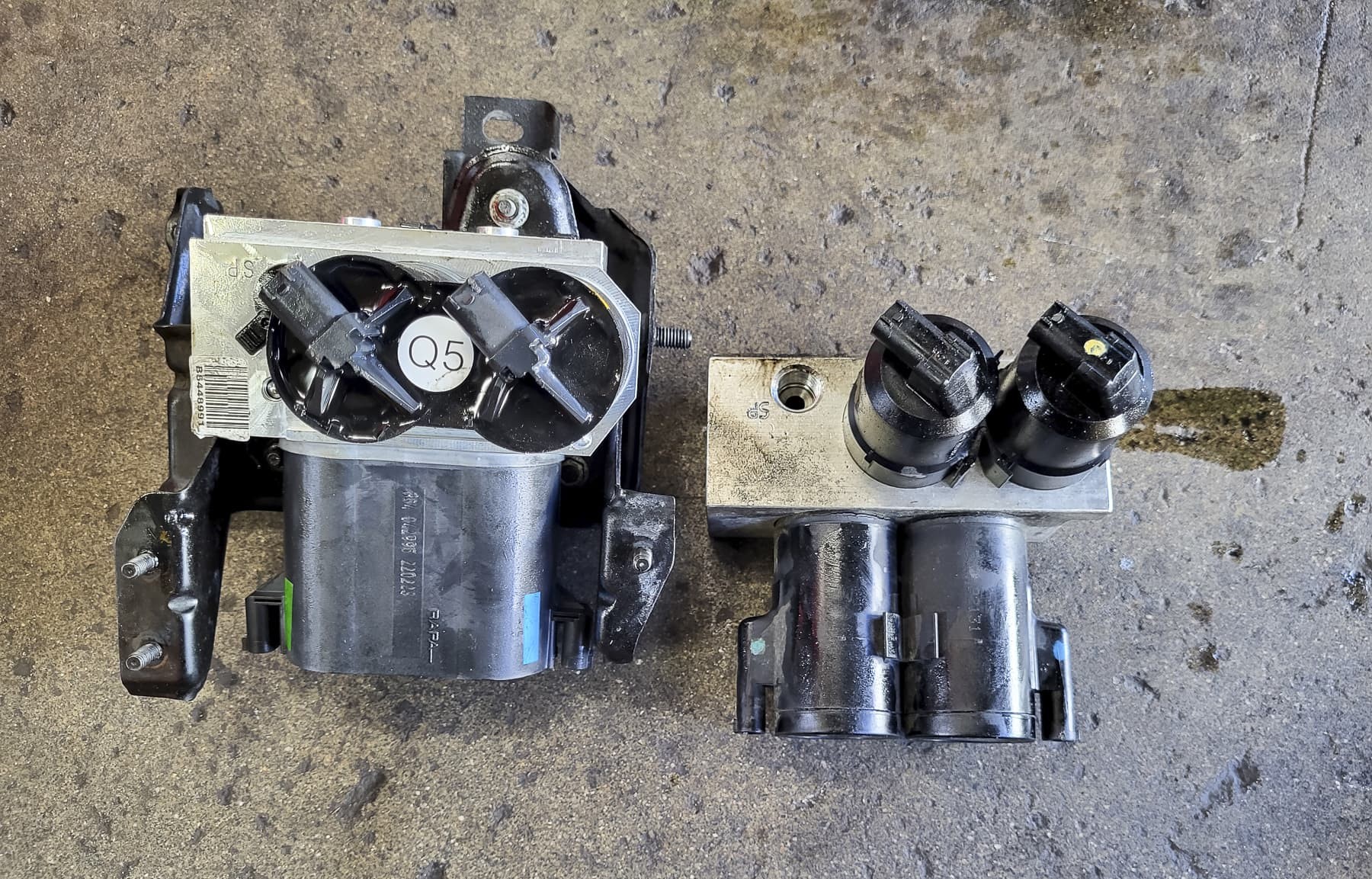

The decision was made to replace the front valve block. These units are responsible for controlling hydraulic fluid flow to each strut, managing pressure and ride height at each corner of the vehicle. Upon removal and comparison with the new replacement unit, a subtle but potentially significant difference was observed.

Old and new ABC valve blocks for a 2003 Mercedes Benz SL500

Old and new ABC valve blocks for a 2003 Mercedes Benz SL500

Comparison of an old and new ABC valve block for a 2003 Mercedes Benz SL500, highlighting potentially larger solenoids in the new unit.

“You notice the solenoids look much larger on the new units,” Bernie points out, comparing the old and new valve blocks side-by-side. This suggests a possible design improvement by Mercedes-Benz to enhance reliability, although valve blocks are not typically frequent failure items due to electrical issues. The larger solenoids may indicate improved sealing or durability against hydraulic pressure over time.

Close-up of solenoid differences in old and new ABC valve blocks

Close-up of solenoid differences in old and new ABC valve blocks

Detailed view showing the solenoid size difference between the original and replacement ABC valve blocks for a 2003 Mercedes SL500.

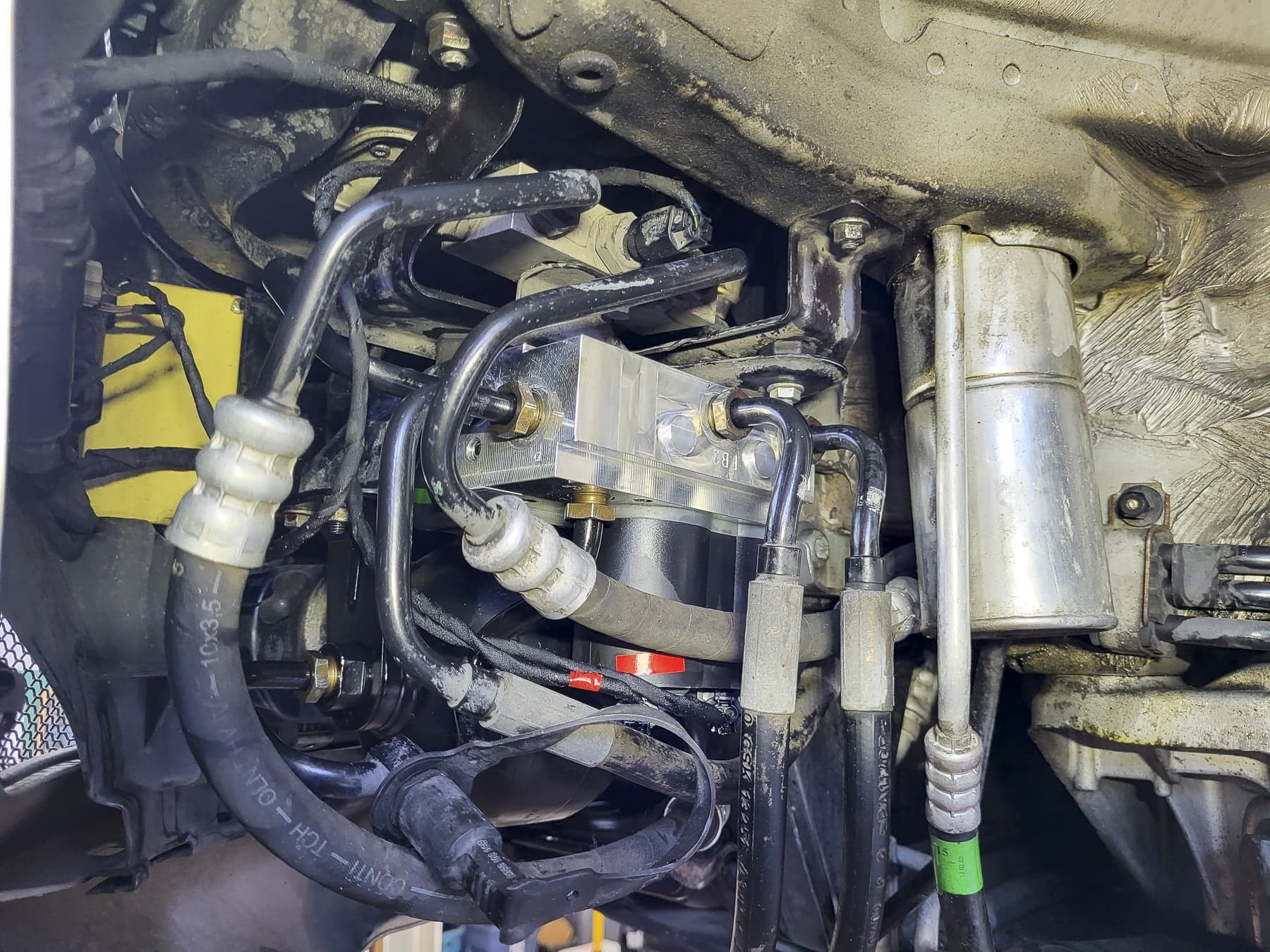

The valve block is located in a somewhat exposed position, behind the front wheel well liner.

2003 Mercedes Benz SL500 showcasing level ABC suspension

2003 Mercedes Benz SL500 showcasing level ABC suspension

The front ABC valve block positioned within the wheel well of a 2003 Mercedes Benz SL500, illustrating its integration with hydraulic lines and electrical connections.

Replacing the front valve block rectified the issue of the 2003 Mercedes SL500 suspension dropping overnight. With the new valve block properly sealing the hydraulic circuits, the system maintained pressure, and the car held its correct ride height.

Maintaining Your ABC Suspension: Fluid Flushes

The ABC system, while impressive, requires maintenance to ensure longevity and prevent costly repairs. Bernie recommends regular fluid flushes as a preventative measure. “You can flush the fluid on ’em and that is a good maintenance service to do every once in a while. And I’d say, you know, once in a while, meaning, every five years type of thing is probably a good amount of time.”

The hydraulic fluid in the ABC system can degrade and become contaminated over time. Flushing the system removes old, dirty fluid and replaces it with fresh, clean fluid. This helps to keep the internal components, including the valve blocks, functioning smoothly and sealing effectively. While not inexpensive due to the specialized fluid and labor involved, regular fluid flushes can be a worthwhile investment compared to major component replacements down the line.

Looking Ahead: Rear Valve Block Considerations

With the front valve block successfully replaced, the 2003 Mercedes SL500’s immediate suspension issue was resolved. However, Bernie anticipates that the rear valve block may also require replacement in the future. “I think probably the rear will be the next thing that needs to be replaced.” Given the age and mileage of the vehicle, and the fact that the front valve block failed, it’s a reasonable expectation that the rear unit, experiencing similar wear and tear, could also develop leaks or malfunctions.

Conclusion

Diagnosing suspension issues in Mercedes-Benz vehicles equipped with ABC can be complex, requiring a systematic approach and expert knowledge. In the case of this 2003 Mercedes SL500, the journey involved addressing multiple components, from struts and accumulators to finally pinpointing the valve block as the source of the persistent suspension drop. This case highlights the importance of thorough diagnostics and the potential for age-related wear in complex hydraulic systems. Regular maintenance, such as ABC fluid flushes, can play a crucial role in prolonging the life and ensuring the optimal performance of these sophisticated suspension systems, keeping your Mercedes-Benz riding smoothly for years to come.

If you are experiencing issues with your Mercedes-Benz ABC suspension or any other automotive concerns in the Vancouver area, the experts at Pawlik Automotive are available to assist. You can book an appointment online at pawlikautomotive.com or call them at (604) 327-7112.