For enthusiasts of the Nissan 300ZX, the 1996 model year presents a unique set of challenges and considerations, primarily due to its adoption of OBD-II. While OBD-II is now a standard and beneficial system in modern vehicles, offering enhanced diagnostic and tuning capabilities, its implementation in the final year of the Z32 in North America created a distinct scenario. The 1996 300ZX, while sharing the iconic Z lineage, became somewhat of an outlier compared to its predecessors when it came to performance modifications and tuning.

The 1996 300ZX experienced a performance reduction compared to earlier models, with approximately 20 less horsepower due to less aggressive camshaft profiles for both manual and automatic transmissions. To illustrate, pre-1996 models (1990-1995) featured intake and exhaust cam durations of 248 degrees for manual transmissions, and 240 intake/248 exhaust for automatics. In contrast, the 1996 model utilized milder 232 intake and 240 exhaust cams, alongside reduced valve lift. Furthermore, the absence of Nissan’s Variable Cam Timing (VTC) system in the ’96 models further contributed to a decrease in overall engine performance across the RPM range. Compounding these mechanical differences, the 1996 300ZX came equipped with a unique OBD-II ECU system. This ECU is known to be more challenging to tune and is prone to triggering diagnostic trouble codes (DTCs) when non-emission-compliant modifications are introduced.

Faced with these obstacles, some 1996 300ZX owners have explored the route of retrofitting pre-1996 components, such as wiring harnesses, ECUs, and camshaft setups. While this approach can potentially mitigate some of the OBD-II related limitations and performance restrictions, it presents complexities, particularly in regions with stringent emissions regulations like California.

However, enthusiasts are finding ways to work within the OBD-II framework and unlock performance from their 1996 Z32s. Consider the case of Alex, a long-term customer with a ’96 300ZX Twin Turbo (TT). Driven by the desire for increased performance, Alex embarked on a series of modifications while navigating the constraints of his OBD-II system.

Freshly painted J-Spec bumper with Powertrix Carbon Fiber Ducts installed on a Nissan 300ZX Z32.

Freshly painted J-Spec bumper with Powertrix Carbon Fiber Ducts installed on a Nissan 300ZX Z32.

Alex’s modification journey included notable upgrades such as 3″ 4-Bolt Downpipes designed for stock turbos, 3″ to 2.5″ Test Pipes, Ash 2.5″ Intercooler Piping with Specialty Z Outlet Pipes and Massive Intercoolers, a Selin Dual POP intake, Nismo 740cc injectors, Z1 Throttle Bodies, a J-Spec bumper, and cooling enhancements for track use.

Ash intercooler piping and components installed on a 1996 Nissan 300ZX Z32 engine bay.

Ash intercooler piping and components installed on a 1996 Nissan 300ZX Z32 engine bay.

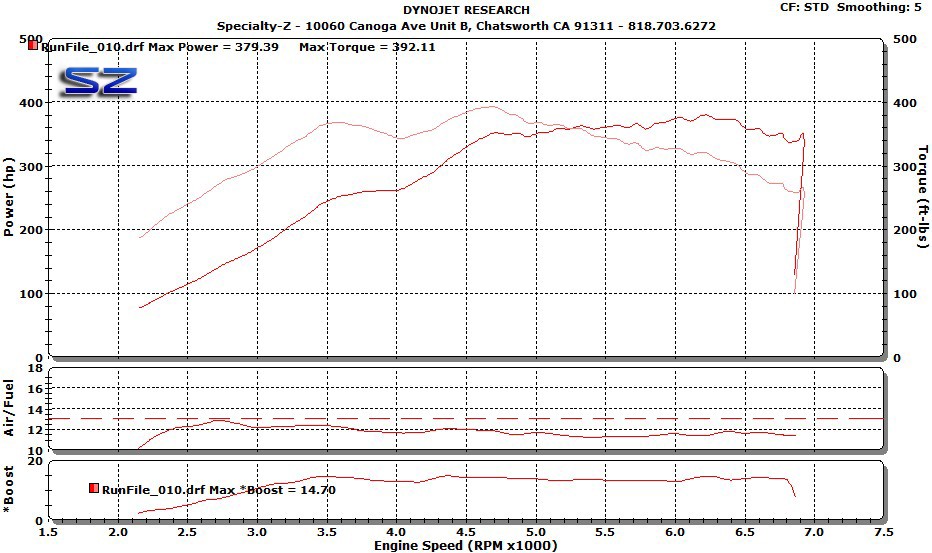

Dyno testing was conducted using 91 octane fuel to assess the results of these modifications on Alex’s 1996 300ZX. Due to the OBD-II limitations and tuning complexities of the ’96 ECU, an AFC (Air Fuel Controller) was utilized for fuel tuning adjustments.

Dyno graph showing horsepower and torque curves for a modified 1996 Nissan 300ZX Z32.

Dyno graph showing horsepower and torque curves for a modified 1996 Nissan 300ZX Z32.

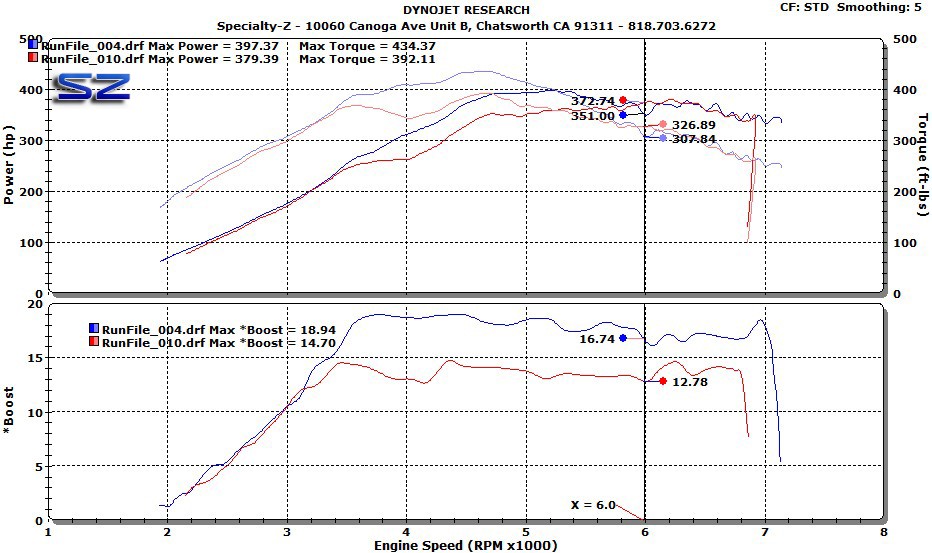

The dyno results highlighted the inherent challenges in extracting significant performance gains from a 1996 300ZX simply by increasing boost and octane. A comparison was made between a 91 octane tune at 14.7 psi of boost and a 100 octane tune at nearly 19 psi. While initial gains were observed up to approximately 5800 RPM, beyond this point, the engine’s efficiency in utilizing the increased boost diminished considerably. Pushing the engine to higher boost levels in this range was deemed to primarily induce stress without a proportional power increase.

Dyno graph comparing 91 octane and 100 octane fuel performance in a modified 1996 Nissan 300ZX Z32, highlighting boost and horsepower differences.

Dyno graph comparing 91 octane and 100 octane fuel performance in a modified 1996 Nissan 300ZX Z32, highlighting boost and horsepower differences.

Interestingly, the dyno testing revealed that at lower boost levels (around 12 psi), the engine demonstrated greater efficiency, producing 20 more horsepower and torque compared to the higher boost, 100 octane configuration. This observation underscores the limitations imposed by the 1996 OBD-II system and ECU in effectively managing and capitalizing on increased boost and higher octane fuel, particularly at higher RPMs. To optimize performance with 100 octane fuel in a ’96 Z32, it would be necessary to limit boost levels beyond 5800 RPM to maintain engine efficiency and avoid undue stress.

Looking ahead, further enhancements for this 1996 300ZX are planned, including the installation of pre-1996 camshafts and the integration of Nissan’s VTC system. Intriguingly, these upgrades are being explored with the aim of retaining the stock OBD-II ECU and wiring harness, potentially through the use of aftermarket modifications designed to work with the existing system and maintain California legal compliance. This approach signals an innovative direction for 300zx Obd2 Conversion and modification, focusing on maximizing performance within the constraints of the factory OBD-II system rather than circumventing it entirely.