For automotive enthusiasts, the quest for power is often limitless. The coveted 1000 horsepower mark is a dream for many, a reality for a select few, and an astounding achievement for a street-legal Nissan 350Z. While the realm of “pure drag” cars frequently boasts such figures, maintaining street driveability at this level of performance is a rare feat. Chris Shively, a dedicated second-generation car aficionado, embarked on a mission to build a Z33 350Z that would not only shatter performance barriers but also captivate show car and car audio enthusiasts alike. His project was a testament to meticulous planning and execution, proving that a Nissan 350z Horsepower figure in the four-digit range is not just a fantasy.

Rear quarter view of a widebody Nissan 350Z in dark grey, showcasing its aftermarket wheels and aggressive stance.

Chris’s journey with his 350Z, purchased in 2003, was always geared towards achieving that monumental 1,000 horsepower target. Recognizing the VQ35 engine platform was still in its early development stages, he wisely chose to observe the aftermarket’s progress, waiting for proven technologies to emerge before investing heavily. Interestingly, unlike many performance builders who prioritize engine modifications first, Chris took a different approach, starting with the car’s aesthetics. This unconventional strategy likely saved him considerable expense in the long run.

Subtle Exterior Transformation

Close-up of a silver iForged wheel with NITTO INVO tire fitted to the widebody Nissan 350Z, highlighting the aftermarket brake caliper.

Aiming for understated yet impactful enhancements to the 350Z’s factory lines, a WALD aero kit was selected to give Chris’s Z a distinctive edge. Demonstrating his hands-on nature, Chris collaborated with a local body shop to skillfully cut and weld the fenders, significantly widening the Z33’s stance. The result was a bespoke wide-body conversion that appeared seamlessly integrated, as if straight from the factory. To complement the widened fenders, the 350Z was fitted with aggressive 19×11-inch iForged wheels at the front and even wider 20×13-inch wheels at the rear. These were wrapped in NITTO INVO tires (285/30R19 front, 345/25R20 rear), providing an immense contact patch for optimal grip. Ensuring formidable stopping power, massive StopTech calipers, featuring six pistons up front and four at the rear, along with larger diameter two-piece rotors, were installed to bring this high-performance machine to a halt effectively.

Custom car audio system installed in the trunk of the Nissan 350Z, featuring multiple amplifiers and subwoofers.

While the engine performance upgrades were strategically delayed, Chris turned his attention to enhancing the interior experience. A competition-grade Swiss Audio sound system was meticulously installed in the cargo area, incorporating five powerful amplifiers and three subwoofers. Within the cabin, four midrange drivers and a pair of tweeters were integrated to reproduce the mid and high frequencies, creating a rich and immersive audio environment. This impressive 4,000-watt system is controlled by a Kenwood GPS/multimedia head unit, seamlessly blending entertainment with technology.

Nissan 350z Fuel Cap Modification

Nissan 350z Fuel Cap Modification

Relocated fuel filler cap behind the license plate on the modified Nissan 350Z.

PowerLab Front Mount Intercooler on 350z

PowerLab Front Mount Intercooler on 350z

PowerLab front mount intercooler visible through the front bumper of the Nissan 350Z, essential for cooling the intake charge in a high horsepower turbocharged application.

(L) The fuel filler has been cleverly relocated behind the license plate for a cleaner aesthetic. (R) The front bumper now houses a PowerLab FMIC with a Garrett core, crucial for managing intake temperatures.

The Pursuit of Horsepower: Engine Overhaul

Once the aftermarket industry had successfully addressed the VQ35’s inherent limitations and developed reliable solutions for achieving 1,000+ wheel horsepower, Chris began the search for a reputable shop to bring his vision to life. Lightspeed Performance, a local engine builder, was initially entrusted with the VQ35 engine build. The cylinder heads underwent porting work and were then upgraded with Ferrea +1mm valves, valve springs, and titanium retainers. TOMEI POWERED 264-degree camshafts were chosen to optimize valve timing events for high-performance operation. The engine short block was then sent to AEBS to be fitted with their newly engineered big displacement kit. AEBS re-sleeved the block, performed boring and honing of the cylinders, and installed 100mm 8.5:1 compression pistons. These large bore pistons were paired with an AEBS 90mm stroker crankshaft and connected using AEBS forged connecting rods, creating a robust foundation for extreme power.

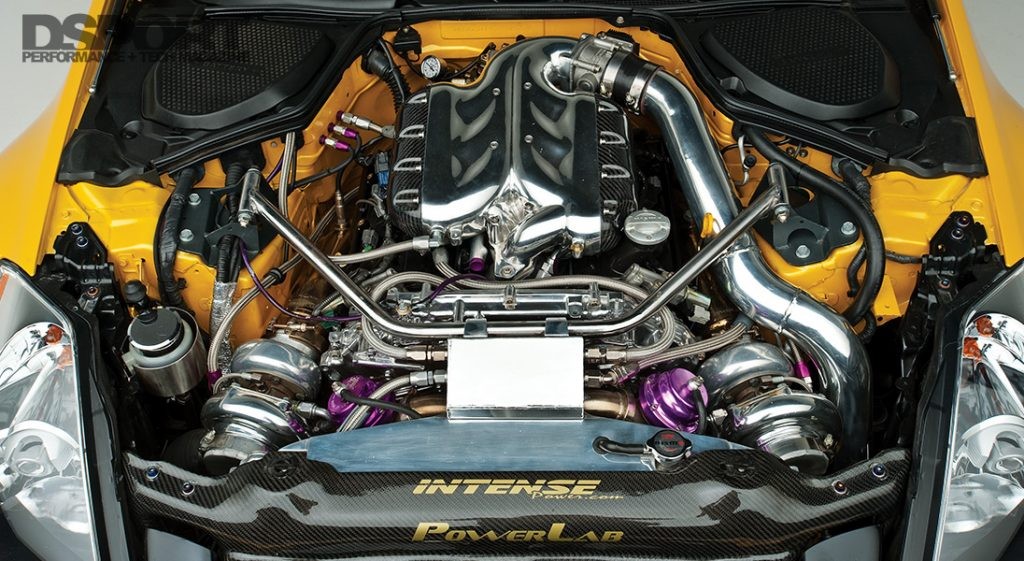

Detailed engine bay shot of the twin-turbocharged, high-horsepower Nissan 350Z, showcasing the clean and functional layout.

Twin Turbocharging and Customization

Close-up of a Garrett GT37R turbocharger, part of the twin-turbo setup on the Nissan 350Z, emphasizing the performance hardware.

Unexpectedly, Lightspeed Performance closed down shortly after completing the engine block assembly, requiring Chris to find a new tuner to finalize the project. Intense Power (IP) in Gilbert, Arizona, was selected to take over and complete the build. IP had already conceived a twin top-mount turbocharger system, but Chris had specific requirements: the air conditioning and power steering systems had to be retained for street usability. Addressing these constraints, IP first relocated the accessories, designing a custom bracket to reposition the A/C compressor. To eliminate the power steering pump, they ingeniously adapted an electronic steering system from a Toyota MR2. With ample space now available in the engine bay, PowerLab (PL) fabricated custom stainless-steel exhaust manifolds. These manifolds were designed to position the Garrett GT37R turbochargers behind each headlight, allowing the compressors to draw cool air from inlets strategically placed behind ducts in the front bumper, optimizing intake air temperatures and 350z horsepower potential.

Fueling the Powerhouse

To satisfy the fuel demands of the enlarged VQ engine at such high horsepower levels, substantial fuel system upgrades were implemented. A dual Walbro 255-lph in-tank fuel pump system was installed to draw VP Racing C16 race fuel from the tank and deliver it to a set of high-flow PowerLab fuel rails. These billet aluminum fuel rails feature increased capacity to ensure that the RC Engineering 1,600 cc/min fuel injectors receive a consistent and ample fuel supply, particularly under high duty cycles. To maintain balanced fuel distribution across all injectors and prevent fuel starvation, a fuel return system was incorporated, regulated by a Mallory adjustable fuel pressure regulator to ensure optimal fuel pressure within the rails.

Another view of the Nissan 350Z engine bay, highlighting the fuel system components and overall engine management setup.

Optimizing Airflow and Engine Strength

The factory intake plenum on the VQ35DE engine presents a design challenge, as its configuration results in less plenum volume for the first two cylinders compared to the remaining four. To rectify this and ensure equal air charge distribution to all cylinders, a Cosworth aluminum intake plenum was installed. The Cosworth intake features a dual-plenum design that effectively delivers airflow evenly to each cylinder, while integrated velocity stacks enhance airflow velocity towards each intake port. Cosworth claims that this design improves both midrange torque and top-end power, crucial for maximizing 350z horsepower.

Recognizing the limitations of the stock engine components under extreme boost conditions, Chris opted for a comprehensive engine strengthening strategy. While factory engines are engineered with a safety margin, this margin diminishes rapidly with forced induction. The stock VQ35DE in the 2003 Nissan 350Z produces around 287 flywheel horsepower, translating to approximately 244 wheel horsepower. It’s generally accepted that the factory engine can reliably handle up to around 400 wheel horsepower before durability becomes a concern. The factory connecting rods and pistons are known to be the weak points at higher power levels.

To achieve his ambitious horsepower goals reliably, simply upgrading pistons and rods wasn’t sufficient. Increasing engine displacement through a larger bore and stroke was deemed essential to improve engine response with the large frame turbochargers. An AEBS large bore stroker kit, complete with 100mm pistons and a 90mm stroke crankshaft, increased the engine displacement to 4,241cc, a significant 21 percent increase over the factory 3.5L displacement. AEBS ductile-iron sleeves were used to reinforce the engine block to accommodate the 100mm pistons and enhance the block’s overall strength to contain the extreme cylinder pressures generated at 1000+ 350z horsepower levels.

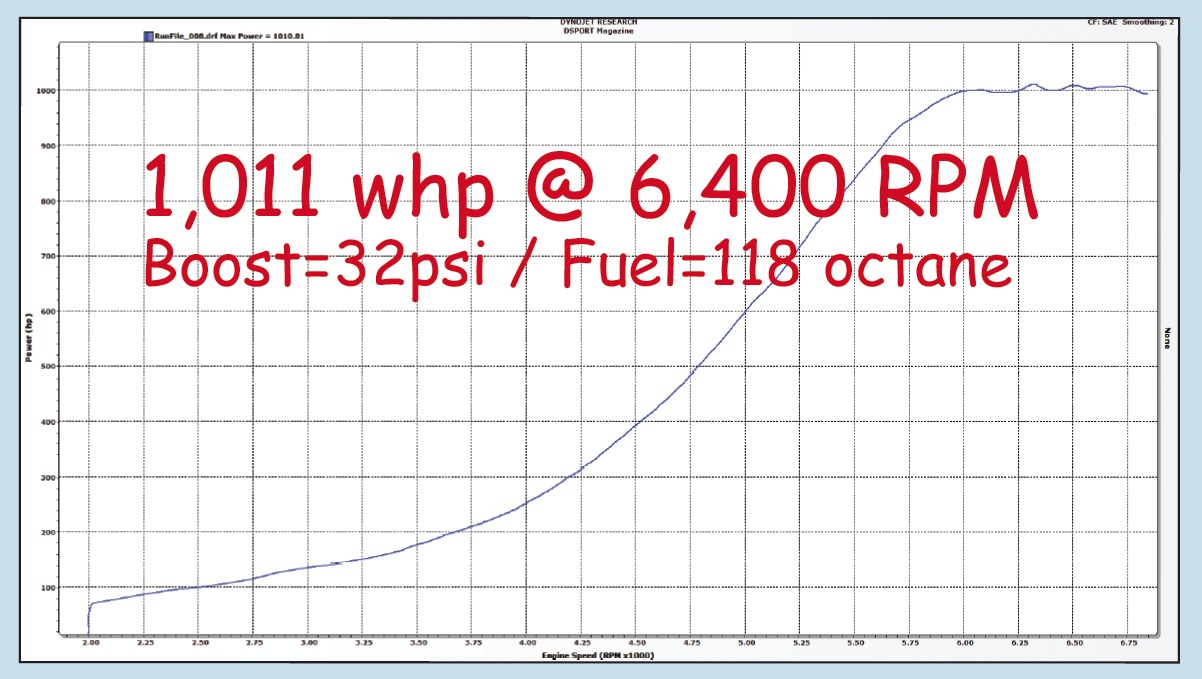

Dyno graph showing the horsepower and torque curves of the modified Nissan 350Z, peaking at over 1000 wheel horsepower.

Engine Management and Tuning for 1000+ WHP

To effectively manage and control an engine producing four-digit horsepower figures, significant upgrades to engine management and fuel delivery systems are indispensable. Twin fuel pumps supply a bank of six RC Engineering 1,600 cc/min fuel injectors with high-octane VP Racing C16 race fuel. A ProEFI Pro48 engine management system (EMS) was selected to precisely control boost pressure, fuel delivery, and ignition timing. Tuned by Jason Siebels on a Dynojet 248 Dynamometer, the modified 350Z successfully achieved its target, delivering an astounding 1,011 horsepower and 876 lb-ft of torque to the wheels at 32 psi of boost pressure. Compared to the stock 244 wheel horsepower of a factory VQ35, this twin-turbo 4.2-liter VQ engine produces over four times the original power output, showcasing the incredible potential for 350z horsepower enhancement.

Side profile shot of the Nissan 350Z, highlighting its widebody modifications and overall aggressive stance.

Mission Accomplished: A 1000 Horsepower Street Weapon

While the extensive build process spanned six years and involved a substantial investment of $150,000, Chris’s satisfaction is palpable. The Z now perfectly embodies his initial vision, excelling in every aspect. He reflects, “A significant amount of time, money, and effort were invested with the aim of creating the cleanest and most technically advanced 350Z possible. From the custom metal wide body to the meticulously built stroker engine and bespoke turbo system, every detail of this car’s design was carefully considered.” He further emphasizes, “What truly distinguishes this machine is the dedicated team of individuals who poured their expertise and passion into bringing it all together.” Just before this feature went to press, Kazuhiko “Smoky” Nagata of TOP SECRET Japan, a legendary figure in automotive tuning, encountered this 350Z at the Anime Matsuri 2010 show in Houston. Smoky, renowned for his discerning taste and engineering expertise, gave this 350Z his unequivocal approval, declaring it the best-engineered car at the show – a validation that resonated deeply with Chris and the team.

Full 350Z Photo Gallery and Spec Sheet on Page 2 >>

Pages: 1 2