Porsche, renowned for its groundbreaking automotive engineering, has recently unveiled patents hinting at a revolutionary engine cycle. Dubbed a “2 x 3-stroke” by Porsche, this innovative design is more accurately described as a 6 Stroke Engine Porsche configuration or a 4 + 2-stroke system. This article delves into the intricacies of this new engine technology, exploring its potential benefits, complexities, and what it could mean for the future of Porsche and engine design as a whole.

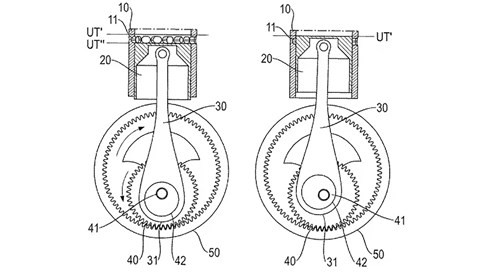

The conventional four-stroke engine cycle, the bedrock of modern combustion engines, operates through four distinct phases: intake, compression, combustion (expansion), and exhaust. Porsche’s novel approach introduces a significant deviation by incorporating a two-stroke event within this established cycle. This is achieved through an ingeniously complex crankshaft arrangement that allows for two different top and bottom dead center positions within the same cycle. Effectively, after the initial expansion phase, the engine engages in a second compression and expansion sequence – the core of the two-stroke addition. However, the system is even more sophisticated than a simple add-on.

Central to Porsche’s innovation is a ‘scavenging’ phase, strategically positioned between the first expansion and the second compression. This is where the unique crankshaft design truly comes into play. This mechanism enables the piston to descend to a ‘lower’ Bottom Dead Center (BDC) compared to the four-stroke segments of the cycle. This deeper descent uncovers a series of scavenge ports that were previously hidden.

Porsche 6 Stroke Engine Patent Diagram – Crankshaft and Piston Mechanism for Novel Combustion Cycle

Porsche 6 Stroke Engine Patent Diagram – Crankshaft and Piston Mechanism for Novel Combustion Cycle

The term ‘scavenging’ itself is borrowed from two-stroke engine terminology. Just before these ports are exposed, the exhaust valves open, releasing some of the combusted gases and reducing cylinder pressure. As the piston uncovers the scavenge ports, pressurized air is forced in, effectively pushing the remaining exhaust gases upwards and out through the exhaust – a process known as ‘uniflow scavenging’. Following this scavenging phase, both the exhaust valves and scavenge ports close, initiating the second compression stroke, culminating in ignition at Top Dead Center (TDC) for the second combustion event.

This secondary combustion is not necessarily aimed at boosting power output. A primary objective could be to significantly reduce emissions by re-burning gases that remain trapped within the cylinder after the initial combustion. Two-stroke engines are known for their compatibility with ‘homogeneous charge compression ignition’ (HCCI), a combustion mode recognized for its efficiency and cleaner operation, often occurring without a traditional spark or flame. While some exhaust gases are expelled during the first exhaust event, a substantial portion can be retained and re-combusted in the subsequent two-stroke phase. However, to maintain emissions control and prevent unburnt air from reaching the exhaust, which would compromise after-treatment systems, power output might be intentionally limited.

While conceptually sound, the 6 stroke engine Porsche design does introduce complexities. The intricate crankshaft, employing hypo-cycloidal gearing reminiscent of a Spirograph, presents a significant mechanical challenge. Piston-controlled ports, while effective, can raise concerns about piston ring wear, although solutions exist, as demonstrated by the reliability of large marine two-stroke engines utilizing uniflow scavenging. Managing oil consumption with piston-controlled ports also requires careful engineering. Furthermore, achieving effective scavenging necessitates boost pressure. The camshafts in this configuration would also need to operate at one-third engine speed, with exhaust valves opening twice per cycle.

One might question the rationale behind such complexity when a simpler uniflow-scavenged two-stroke engine could potentially achieve similar goals. The automotive industry harbors a strong bias against two-stroke engines, which might explain Porsche’s approach to innovate within the familiar framework of a four-stroke cycle while incorporating two-stroke elements. This 6 stroke engine porsche concept, while arguably more intricate, represents a fascinating exploration into novel combustion strategies, pushing the boundaries of engine technology in pursuit of enhanced efficiency and reduced emissions. Whether this patented technology will make its way into future Porsche models remains to be seen, but it undoubtedly showcases Porsche’s commitment to innovation and forward-thinking engineering in the realm of internal combustion engines.