Experiencing trouble with your 1996 Ford F150 5.8L and seeing OBD2 codes P0172 and P0174 pop up? You’re not alone. These codes, indicating a “System Too Rich (Bank 1)” (P0172) and “System Too Lean (Bank 2)” (P0174), can be frustrating, especially since they might not appear during normal driving but surface when towing or under heavy acceleration. Let’s dive into understanding these codes and how to diagnose the potential issues in your 1996 F150 5.8L engine.

Understanding OBD2 Codes P0172 and P0174 on a 1996 F150 5.8L

These diagnostic trouble codes (DTCs) signal that your engine’s computer, the Powertrain Control Module (PCM), is detecting an imbalance in the air-fuel mixture in your engine. Specifically:

- P0172 (System Too Rich, Bank 1): This means Bank 1 (the side of the engine containing cylinder #1) is receiving too much fuel compared to air.

- P0174 (System Too Lean, Bank 2): Conversely, Bank 2 is not getting enough fuel for the amount of air, resulting in a lean condition.

It might seem contradictory to have one bank running rich and the other lean simultaneously. However, this can point towards issues that affect each bank differently or a sensor that is providing skewed data leading to misinterpretations by the PCM.

Common Symptoms Accompanying P0172 and P0174

Beyond the check engine light and the stored codes, you might notice several performance issues with your 1996 F150 5.8L:

- Hard Starting: The engine might take longer to crank and start, especially when cold.

- Rough Idle: An uneven or shaky idle, sometimes described as “coughing” at low RPMs, particularly when the engine is warm.

- Hesitation or Stalling: The engine may hesitate upon acceleration or even stall, especially during initial warm-up.

- Lack of Power: Reduced engine power, especially noticeable when accelerating or under load (like pulling a trailer).

- Spark Knock/Detonation: A pinging or knocking sound from the engine, particularly under heavy load or wide-open throttle (WOT).

- Poor Fuel Economy: While not always immediately apparent, fuel consumption might increase.

Diagnosing the Root Cause of P0172 and P0174 in Your 1996 F150 5.8L

Troubleshooting these codes on your 1996 F150 5.8L requires a systematic approach. Here’s a breakdown of potential culprits and diagnostic steps, focusing on the Mass Air Flow (MAF) sensor as highlighted in a Ford Service Tip:

1. Mass Air Flow (MAF) Sensor Contamination

A contaminated MAF sensor is a prime suspect, especially given the Ford Technical Service Bulletin (TSB) that addresses this exact issue for vehicles of this era. The TSB (98-23-10) points out that MAF sensors can become contaminated by dirt, oil, silicon, and even spider webs.

How Contamination Affects Readings:

- Idle: A contaminated MAF can overestimate airflow at idle, causing the PCM to reduce fuel, potentially leading to lean long-term fuel trims.

- High Air Flow (WOT/Load): Under high airflow conditions, the same contamination can cause the MAF to underestimate airflow. This is critical because at WOT, the engine typically goes into open loop and relies on learned fuel trims. If the MAF is underreporting air, and the learned trims are lean (from idle), the engine can run dangerously lean under load, triggering P0174 and potentially P0172 if the overall system tries to compensate unevenly.

Diagnostic Steps for MAF Sensor:

- Visual Inspection: Carefully remove the MAF sensor and inspect the sensing wires for any visible contamination. Look for dirt, debris, or oil film.

- MAF Sensor Cleaning: Use a dedicated MAF sensor cleaner to gently clean the sensor wires. Do not use anything else, as other cleaners can damage the delicate sensor.

- Live Data Reading: Use an OBD2 scanner to read live data from the MAF sensor. Monitor:

- MAF readings at idle: Compare to expected values for your 5.8L engine (consult a repair manual or online resources for typical ranges).

- MAF readings at Wide Open Throttle (WOT): Observe if the MAF readings increase smoothly with RPM and throttle input.

- Barometric Pressure (BARO) Reading: The PCM infers BARO based on MAF readings. A consistently low BARO reading can indicate a contaminated MAF sensor is underestimating airflow and making the PCM think the vehicle is at a higher altitude. Compare the BARO reading to your local weather barometric pressure for verification.

2. Vacuum Leaks

Vacuum leaks can introduce unmetered air into the engine, leaning out the mixture, particularly affecting Bank 2 in some scenarios if the leak is more prominent on that side of the intake manifold.

Diagnostic Steps for Vacuum Leaks:

- Visual Inspection: Carefully inspect all vacuum hoses for cracks, looseness, or disconnections. Pay close attention to hoses around the intake manifold, throttle body, and vacuum-operated components.

- Spray Test: With the engine idling, carefully spray a small amount of carburetor cleaner or brake cleaner around vacuum hose connections and the intake manifold gasket areas. Listen for changes in engine RPM. An increase in RPM indicates a vacuum leak in that area as the engine is sucking in the spray. (Note: Be cautious when using flammable sprays around a hot engine).

3. Fuel Delivery Issues

Problems with fuel delivery can also cause lean conditions (P0174) and potentially indirectly contribute to rich conditions (P0172) if the system tries to compensate unevenly.

Potential Fuel Delivery Issues:

- Fuel Filter: A clogged fuel filter can restrict fuel flow. You mentioned replacing the fuel filter recently, but it’s worth considering if it could be prematurely clogged or if there’s another fuel restriction.

- Fuel Pump: A failing fuel pump may not deliver adequate fuel pressure, especially under higher demand conditions like towing or acceleration.

- Fuel Pressure Regulator: A faulty fuel pressure regulator could cause incorrect fuel pressure.

- Clogged or Faulty Fuel Injectors: While less likely to cause lean on one bank and rich on another simultaneously, injector issues are still possible.

Diagnostic Steps for Fuel Delivery:

- Fuel Pressure Test: Use a fuel pressure gauge to check the fuel pressure at the fuel rail. Compare the reading to the specification for your 1996 F150 5.8L.

- Injector Balance Test (Advanced): Involves checking the flow rate and spray pattern of each fuel injector, typically requiring specialized equipment or professional diagnosis.

4. Oxygen (O2) Sensors

While less directly implicated in causing both P0172 and P0174 simultaneously, faulty O2 sensors can provide incorrect feedback to the PCM, leading to incorrect fuel trim adjustments. However, with P0172 and P0174, it’s more likely the issue is upstream of the O2 sensors, affecting both banks differently or being misinterpreted.

Diagnostic Steps for O2 Sensors:

- Live Data Monitoring: Use an OBD2 scanner to monitor the O2 sensor readings (especially upstream sensors – Bank 1 Sensor 1 and Bank 2 Sensor 1). Look for erratic or sluggish readings.

- Sensor Testing (Advanced): Involves testing the sensor’s voltage output and response time, often requiring a multimeter and understanding of O2 sensor operation.

Conclusion: A Step-by-Step Approach to Resolving P0172 and P0174

For your 1996 F150 5.8L exhibiting P0172 and P0174, especially under load, starting with the MAF sensor is a logical first step based on the symptoms and the Ford TSB.

Recommended Troubleshooting Steps:

- Inspect and Clean the MAF Sensor: Visually inspect and clean the MAF sensor using MAF cleaner.

- Check for Vacuum Leaks: Perform a thorough visual inspection and spray test for vacuum leaks.

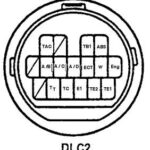

- Monitor Live Data: Use an OBD2 scanner to monitor MAF readings, BARO pressure, and fuel trims at idle and under load.

- Fuel Pressure Test: Check fuel pressure to rule out fuel delivery issues.

If these steps don’t resolve the issue, further investigation into fuel injectors, O2 sensors, and potentially more complex engine management system components might be necessary. While dealer diagnostic equipment can be helpful, a systematic approach and understanding of these common causes can often pinpoint the problem without needing specialized tools in many cases. Remember to always consult your vehicle’s repair manual for specific procedures and specifications.