The concept of MVP, or Minimum Viable Product, has become increasingly popular in product development across various industries. While often discussed in software and tech, the principles of MVP are highly relevant to the automotive world, especially when we consider the evolution of car models and makes. Let’s delve into how understanding MVP can revolutionize the way we think about car development, moving beyond just delivering a complete “car” at once.

A few years ago, a simple illustration captured the essence of iterative and incremental development, lean startup methodologies, and the MVP concept. This visual has since spread widely, resonating with many in the agile and lean communities.

Understanding the Minimum Viable Product concept through a car development metaphor.

While the metaphor uses car development, it’s crucial to remember it’s about product development in general. However, given our focus on “Car Model Vs Make,” we can certainly apply these principles directly to the automotive industry. This article will explore these ideas, emphasizing how an MVP approach can lead to better car models and ultimately, stronger car makes.

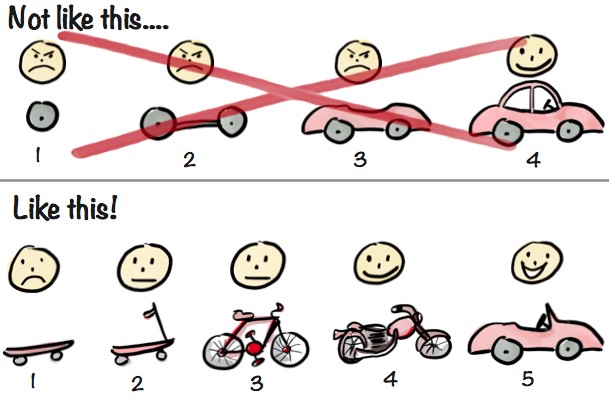

The Pitfalls of Traditional Car Development: “Not Like This”

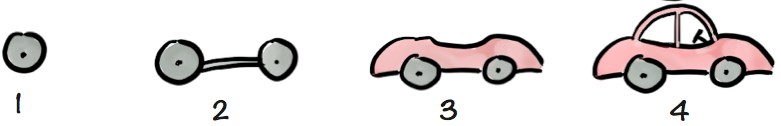

Traditional car development often resembles the top row of the illustration – a linear, sequential approach where each component is developed in isolation before final assembly. This “Big Bang” delivery method is fraught with risks.

The flawed approach to iterative development, delivering unusable car parts.

The flawed approach to iterative development, delivering unusable car parts.

Imagine a car manufacturer developing parts in isolation, delivering them incrementally to a customer who ordered a complete vehicle.

“Sir, iteration one – here’s a tire. What do you think?”

Delivering a tire as the first iteration in car development – an unusable piece.

The customer’s likely reaction? Confusion and frustration. “I ordered a car! What am I supposed to do with a single tire?”

As development continues, more parts arrive, each individually closer to completion, yet still failing to provide a usable product.

Further iterations of unusable car parts, still not a functional vehicle.

Further iterations of unusable car parts, still not a functional vehicle.

Finally, the complete car arrives. The customer might initially seem satisfied, having received what was “ordered.”

The “final product” delivered after a flawed iterative process.

However, in reality, this approach is highly problematic. Months or years have passed without real-world user feedback. The final car model might be based on outdated assumptions, missing crucial features, or simply not meeting the current market needs. The initial vision of the “car” might be completely misaligned with what customers truly desire. This “bastardized agile” approach, while seemingly iterative, lacks the crucial feedback loop that defines true agility and effective product development. It’s a path to potentially irrelevant car models and struggling car makes.

Embracing the MVP Approach: “Like This!”

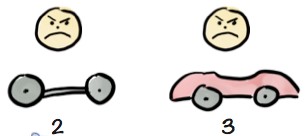

The second row of the illustration presents a fundamentally different, and far more effective, strategy for car model development – mirroring the true essence of MVP.

The MVP approach to product development, focusing on functional iterations.

The MVP approach to product development, focusing on functional iterations.

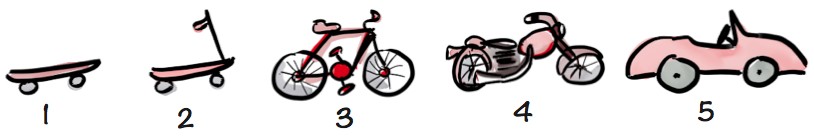

Instead of focusing on building a complete car from the outset, the MVP approach starts with understanding the core need: “I need to get from point A to point B efficiently.” A car is just one solution. The focus shifts to delivering the smallest possible increment that addresses this need and allows for immediate user feedback. This initial increment is the Earliest Testable Product (ETP), or what some might playfully call the “skateboard version” of the car.

The “skateboard” – the Earliest Testable Product, fulfilling the basic need for mobility.

The customer, initially expecting a car model, receives a skateboard. Disappointment is understandable, but the crucial point is not immediate customer satisfaction, but learning. The goal is to get the ETP into the hands of users – in this case, perhaps internal testers or early adopters – to gather invaluable feedback. The communication is key: “We are aiming for a car, but this skateboard is the first step. Use it, test it, and tell us what you think.”

This early feedback can be transformative. Imagine the customer using the skateboard and saying, “It’s okay, but I hate the color!” A seemingly minor detail, but incredibly valuable information learned early in the process, potentially saving significant resources by avoiding a costly mistake in the final car model design.

The core question becomes: “What is the quickest and cheapest way to start learning?” Could we deliver something even simpler than a skateboard initially? Perhaps a bus ticket?

A “bus ticket” – an even simpler ETP, testing the core need for transportation.

A “bus ticket” – an even simpler ETP, testing the core need for transportation.

While a bus ticket isn’t a car component, it tests the fundamental need – transportation. This extreme example highlights the principle of validating core assumptions early and iteratively. Lean Startup methodologies emphasize formulating hypotheses about user needs and systematically validating or invalidating them through these early product iterations.

Returning to the skateboard, feedback emerges: “It’s fun and faster in the office, but unstable and difficult to control.” The next iteration focuses on addressing this feedback.

The “scooter” – addressing stability issues from skateboard feedback.

The scooter emerges, offering improved stability. Users can now navigate more effectively and provide further feedback. Perhaps they now complain about distance limitations and lack of brakes. This leads to the next iteration – the bicycle.

The “bicycle” – expanding usability based on scooter feedback, introducing longer range and control.

The bicycle significantly expands usability. Users can now travel across campus, experiencing fresh air and maneuverability. Crucially, throughout this process, valuable insights are gained: customers appreciate open-air travel, the primary need is campus transportation, and perhaps car-sized vehicles are impractical on campus pathways.

The bicycle might even prove to be a superior solution to the originally envisioned car model for this specific context. The iterative process, guided by user feedback, can lead to unexpected and beneficial product pivots, saving time, resources, and ultimately delivering a more relevant product.

It’s important to acknowledge that upfront analysis is valuable. However, no amount of analysis can fully replace real-world user interaction. Prototype and release early to truly understand user needs and validate assumptions.

The journey continues. Perhaps users now require longer-distance travel. The next iteration introduces an engine, evolving the bicycle into a motorcycle.

The “motorcycle” – adding power and range based on bicycle usage feedback.

The motorcycle offers increased speed and range. Again, feedback guides development. Perhaps users now express a desire for weather protection and passenger capacity. This iterative evolution, driven by user feedback and focused on the core need, can eventually lead to the “car” initially envisioned, or something even better.

In this example, the final iteration becomes a convertible car. Why? Because through the iterative process, it was discovered that users valued open-air driving, a preference that might have been missed in a traditional, upfront-planning approach.

The “car” – the final product, evolved through iterative feedback, incorporating user preferences like a convertible top.

The customer is delighted – not just with a car, but with a car model that truly reflects their needs and preferences, discovered and refined through an iterative MVP approach. This process highlights how focusing on the underlying need and embracing early feedback can lead to superior car models and stronger, more customer-centric car makes.

Finding Your Automotive “Skateboard”

The critical takeaway is to identify your “skateboard” in the automotive context. For a new car model, the skateboard is the earliest testable product – a functional prototype, perhaps even a digital simulation or a basic mule vehicle, that allows for early user feedback.

For established car makes, the skateboard could be a new feature concept tested with a small user group, or a limited-release version of an existing model with a specific upgrade. The key is to move away from Big Bang releases and embrace iterative development.

In the automotive industry, where development cycles are traditionally long and complex, adopting an MVP approach can offer significant advantages:

- Reduced Risk: Early feedback minimizes the risk of developing car models that miss market needs.

- Faster Time to Market: Iterative development allows for quicker releases of functional versions, even if initially limited in features.

- Increased Customer Relevance: User feedback directly shapes the product, ensuring closer alignment with customer desires.

- Cost Efficiency: Early validation prevents wasted resources on features or designs that are not well-received.

Let’s consider some examples, reimagined through an automotive lens.

Automotive MVP Examples

While the original article provides examples like Spotify and Minecraft, let’s think about how MVP principles apply to the automotive industry.

Example 1: Early Car Infotainment Systems

[Spotify Example Image – Repurposed for Infotainment Concept]

Early car radio prototypes – the “skateboard” of in-car entertainment.

Early car radio prototypes – the “skateboard” of in-car entertainment.

Think back to the early days of car radios. Instead of immediately developing complex infotainment systems, early car manufacturers started with basic radios – their “skateboard.” These early systems focused on the core need: in-car audio entertainment. Feedback on these basic systems – sound quality, ease of use, reception – paved the way for more sophisticated car audio and eventually, integrated infotainment systems we see today. Imagine if car manufacturers had tried to launch today’s complex systems without this iterative evolution!

Example 2: Concept Cars as MVPs

[Minecraft Example Image – Repurposed for Concept Car]

Concept cars – testing radical designs and features with potential users.

Concept cars – testing radical designs and features with potential users.

Concept cars are essentially MVPs for radical design and technology innovations. They are often functional prototypes, showcasing new ideas to the public and gathering feedback at auto shows and through media reviews. This feedback helps car makes gauge public reaction to new styling, engine technologies, or interior features before committing to full-scale production. The Minecraft example, highlighting rapid iteration and user engagement, mirrors how concept cars allow for “early and often” feedback on automotive innovations.

Example 3: Limited Edition Models for Feature Testing

[Government Project Example Image – Repurposed for Limited Edition Car]

Limited edition car models – testing new features with a focused user group.

Limited edition car models – testing new features with a focused user group.

Car manufacturers often release limited edition models or trim levels to test new features in a real-world setting before wider rollout. This is analogous to the Swedish Police project example, where a system was rolled out to a limited region and user group first. A limited edition car with a novel technology, like advanced driver-assistance systems (ADAS) or a new type of interior material, acts as an MVP. Feedback from early adopters of these limited editions informs decisions about broader implementation in future car models and makes.

Example 4: Digital Car Customization Platforms

[Lego Example Image – Repurposed for Digital Car Customization]

Digital car configurators – early user testing of design preferences and feature combinations.

Digital car configurators – early user testing of design preferences and feature combinations.

Before physical prototypes, car manufacturers utilize digital car configurators on their websites. These platforms allow potential customers to “build” their ideal car model, experimenting with different trims, colors, and features. This digital MVP gathers valuable data on customer preferences, helping manufacturers understand popular feature combinations and design choices before committing to production. The Lego example, emphasizing early user testing, resonates with how these digital tools provide early feedback on car design and feature appeal.

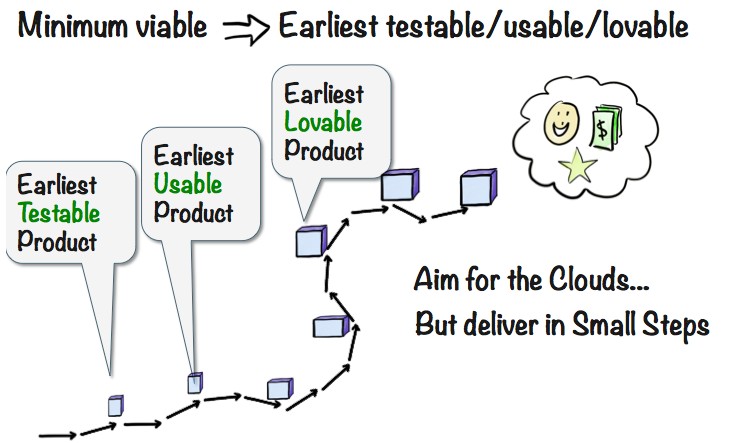

Beyond “MVP”: Earliest Testable, Usable, Lovable Car Models

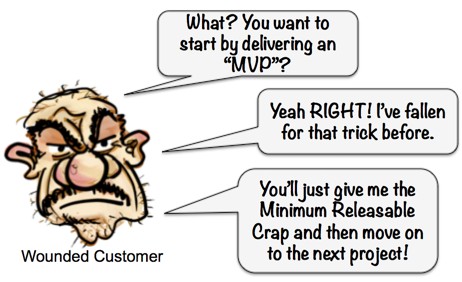

The term MVP, while useful, can be misinterpreted. In the automotive context, just as in software, it can be helpful to refine the terminology to be more explicit.

[MRC Image – Repurposed for “Minimum Releasable Car”]

The risk of MVP being perceived as “Minimum Releasable Car,” lacking essential features.

The risk of MVP being perceived as “Minimum Releasable Car,” lacking essential features.

The fear of “Minimum Releasable Crap” is real. Customers don’t want a minimal, barely functional car. Therefore, thinking in terms of Earliest Testable, Usable, and Lovable Products is more helpful.

Refining MVP into Earliest Testable, Usable, and Lovable Product stages.

Refining MVP into Earliest Testable, Usable, and Lovable Product stages.

- Earliest Testable Car (ETC): This could be a mule vehicle, a digital simulation, or even detailed design sketches. The goal is to test fundamental concepts and gather initial feedback – “Does this engine concept work? Is this design direction appealing?”

ETC Examples: Mule vehicle testing core mechanics; Digital simulation evaluating aerodynamics.

ETC Examples: Mule vehicle testing core mechanics; Digital simulation evaluating aerodynamics.

- Earliest Usable Car (EUC): This is a functional prototype, perhaps a limited production run for early adopters or fleet testing. It’s usable but not feature-complete. Feedback focuses on usability, performance in real-world conditions, and identifying critical improvements.

EUC Example: Limited production run for fleet testing, gathering real-world usage data.

- Earliest Lovable Car (ELC): This is the first truly marketable car model. It’s not perfect, but it offers a compelling value proposition, generating positive reviews and customer enthusiasm. It’s a car people want to buy and recommend. Development continues beyond this point, but the ELC marks the achievement of a viable and desirable product.

ELC Example: Launch of a new car model that generates excitement and positive reviews.

Key Takeaways for Automotive Innovation

In conclusion, applying MVP principles to car model and make development offers a powerful path to innovation and customer-centricity.

- Embrace Iteration, Ditch “Big Bang”: Avoid long, linear development cycles. Adopt iterative and incremental approaches.

- Find Your “Skateboard” (or ETC): Identify the earliest testable form of your car innovation. Start small and learn fast.

- Focus on Learning and Feedback: Prioritize user feedback at every stage. Let feedback guide development decisions.

- Refine Your Terminology: Consider “Earliest Testable/Usable/Lovable Car” to clarify the goals of each development stage.

Remember, the car metaphor is just that – a metaphor. However, the underlying principles of MVP are directly applicable to the automotive industry. By embracing iterative development and prioritizing user feedback, car makes can create more successful car models, stay ahead of the curve in a rapidly evolving market, and ultimately deliver vehicles that truly resonate with drivers.