The Clubman Automobile, a fascinating vehicle with roots in the Triumph Herald chassis, has recently sparked renewed interest thanks to resurfaced design drawings detailing its unique construction. Originally known as the Canstel, this car, produced in Sydney during the late 60s and early 70s, showcases significant chassis modifications aimed at enhancing performance and handling. Approximately 103 units were manufactured, making it a relatively rare and intriguing subject for classic car enthusiasts and those interested in automotive engineering.

The Canstel Clubman: A Blend of Triumph and Ford

The Canstel Clubman, as it was initially named, was conceived using the Triumph Herald as its base. However, it was far from a mere replica. To create a more robust and performance-oriented vehicle, extensive modifications were implemented, particularly to the chassis. While some models retained Triumph engines, the majority were equipped with Ford powerplants, reflecting a pragmatic approach to performance and parts availability. Interestingly, some Clubman automobiles also featured rotoflex rear suspension, a sophisticated system for the era, offering improved handling characteristics.

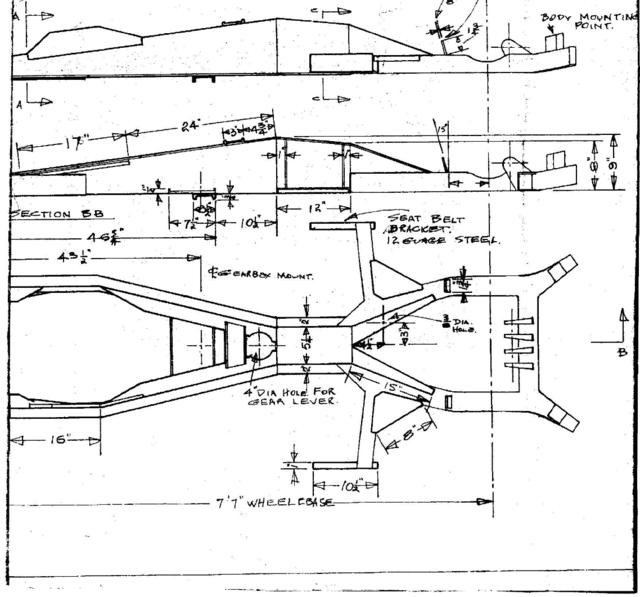

Drawing of Clubman chassis modifications highlighting stiffening elements

Drawing of Clubman chassis modifications highlighting stiffening elements

Key Chassis Reinforcements for Enhanced Rigidity

The newly rediscovered drawings reveal the intricate chassis modifications undertaken to stiffen the Clubman automobile. These modifications were crucial for improving the car’s structural integrity and handling dynamics. By reinforcing key areas of the Herald chassis, the Canstel engineers aimed to create a platform capable of withstanding higher performance demands and delivering a more responsive driving experience. These reinforcements likely involved welding additional metal sections and strategically altering the chassis structure to minimize flex and maximize rigidity.

Rotoflex Suspension and Rear Camber Adjustment

One particularly noteworthy feature discussed among enthusiasts is the use of rotoflex rear suspension in some Clubman models. This system, along with a clever bracket mounting for the lower rear wishbone inner pivot, allowed for fine-tuning of the rear camber. The use of an eccentric washer in this bracket is a testament to the engineering ingenuity of the time, providing a relatively simple yet effective method for adjusting rear camber – a technique still employed in modern production cars. This adjustability is crucial for optimizing handling and tire wear, particularly in performance-oriented vehicles like the Clubman automobile.

Detailed view of the bracket mounting and eccentric washer for rear camber adjustment in a Clubman automobile

Detailed view of the bracket mounting and eccentric washer for rear camber adjustment in a Clubman automobile

Echoes in Racing Heritage: GT6+ and Group 44

The discussion surrounding the Clubman automobile chassis modifications also brings to mind the Triumph GT6+, particularly the Group 44 racing variant. Enthusiasts have noted similarities in the rear suspension adjustments between the Clubman and the Group 44 GT6+. The Group 44 GT6+ featured similar camber adjustment mechanisms and even incorporated a special differential spring mount for left/right spring adjustment, aimed at facilitating corner weighting for racing. These parallels highlight a shared pursuit of handling precision and performance enhancement in both the Clubman road car and the GT6+ race car.

A Lasting Legacy of Automotive Ingenuity

The Clubman automobile, with its meticulously modified chassis and thoughtful engineering solutions, represents a significant chapter in automotive history. Its blend of Triumph and Ford components, coupled with innovative suspension and chassis design, showcases the ingenuity applied to create a unique and capable vehicle. For those passionate about classic cars and automotive engineering, the Clubman automobile and its chassis modifications offer a compelling case study in enhancing vehicle performance through clever design and adaptation.