Navigating the complexities of vehicle maintenance can often feel like deciphering a foreign language. Among the most common terms in modern automotive diagnostics are Codes For Obd2. If you’re managing a fleet or simply keen on understanding your vehicle better, grasping the basics of OBD2 codes is essential. These codes are essentially your car’s way of communicating potential issues, acting as an alert system for everything from minor glitches to significant malfunctions under the hood.

This comprehensive guide will demystify OBD2 codes, explaining what they are, how they function, and why understanding them is crucial for effective vehicle care and fleet management. We’ll explore the different types of OBD2 codes, how to read and interpret them, and strategies for both clearing and preventing these codes. Whether you’re a seasoned fleet manager or a vehicle owner eager to learn, this guide will equip you with the knowledge to confidently handle OBD2 diagnostics.

Understanding OBD2 Codes: The Language of Your Vehicle

On-Board Diagnostics II (OBD2) codes are standardized alphanumeric codes that your vehicle’s computer system uses to report detected problems. Think of them as digital messages from your car, alerting you to irregularities within its various systems.

Modern vehicles are equipped with a sophisticated network of sensors and modules that constantly monitor the engine, transmission, emissions systems, and other critical components. When these systems detect an issue that falls outside of normal operating parameters, the onboard computer generates a specific OBD2 code.

These diagnostic trouble codes (DTCs) are designed to pinpoint the source of the problem, ranging from minor sensor malfunctions to more serious mechanical failures. The illumination of the “Check Engine” light on your dashboard is often the first sign that an OBD2 code has been triggered, indicating that something within your vehicle’s engine or related systems isn’t functioning as expected.

To access these codes, you’ll need an OBD2 scanner or code reader. This device connects to your vehicle’s OBD2 port, typically located beneath the dashboard. Once connected, the scanner retrieves the stored trouble codes, providing a numerical representation of the detected issue. These car repair codes offer valuable insights, guiding you or your mechanic in diagnosing the exact nature of the problem and making informed decisions about vehicle maintenance and repair. Understanding OBD-II codes meaning is the first step towards proactive vehicle care.

Decoding the Types of OBD2 Codes

When the check engine light illuminates and an OBD2 code is triggered, identifying the type of code is the initial step in effective diagnosis. OBD2 codes are categorized into four primary types, each relating to a different area of your vehicle. Recognizing these categories helps to narrow down the potential problem and streamline the diagnostic process.

Powertrain Codes: Engine and Transmission Issues

Powertrain codes are perhaps the most frequently encountered type of OBD2 code. They are denoted by the letter “P” as the first character and signal problems within the powertrain system, which includes the engine, transmission, and related drivetrain components. These codes are critical as they often relate to issues that directly impact the vehicle’s performance and efficiency.

For example, the powertrain code P0300 indicates “Random/Multiple Cylinder Misfire Detected.” This code suggests that one or more cylinders in the engine are not firing correctly, which can lead to reduced engine power, poor fuel economy, and increased emissions. Another common powertrain code, P0171, signifies “System Too Lean (Bank 1),” pointing to an issue with the fuel-air mixture being too lean in one of the engine’s cylinder banks. Addressing powertrain codes promptly is crucial for maintaining vehicle performance and preventing more extensive engine damage.

Body Codes: Comfort and Convenience Systems

Body codes, identified by the letter “B,” relate to issues within the vehicle’s body systems. These systems encompass a wide range of features, including airbags, power windows, electronic mirrors, climate control, and lighting systems. While body codes may not always directly affect the vehicle’s drivability, they can impact safety, comfort, and convenience.

An example of a body code is B0010, which could indicate a problem with the passenger-side front airbag deployment loop. This code is a serious safety concern as it suggests the airbag system may not function correctly in a collision. Another example is B1342, which might point to an issue with the Electronic Climate Control (ECC) system, potentially affecting heating or air conditioning performance. Diagnosing and addressing body codes ensures that all vehicle safety and comfort features are functioning as intended.

Chassis Codes: Steering, Suspension, and Braking

Chassis codes, beginning with the letter “C,” indicate problems within the vehicle’s chassis systems. These systems are fundamental to the vehicle’s handling, ride quality, and safety, including components like the anti-lock braking system (ABS), traction control, electronic stability control, power steering, and suspension systems.

A common chassis code is C0051, which could signal a problem with the brake pressure sensor. A malfunctioning brake pressure sensor can affect the performance of the ABS and stability control systems, potentially compromising braking effectiveness and vehicle stability, especially in emergency situations. Another chassis code, C1201, could indicate an issue with the ABS control module. Prompt attention to chassis codes is vital for maintaining safe driving conditions.

Network Communication Codes: Electronic Communication Issues

Network communication codes, starting with the letter “U,” relate to problems within the vehicle’s communication network. Modern vehicles utilize complex communication networks to allow various electronic control units (ECUs) and modules to exchange data. These codes indicate disruptions in this communication, which can lead to a wide array of symptoms depending on the affected systems.

For instance, the network communication code U0101 signifies “Lost Communication With TCM (Transmission Control Module).” This code indicates that the engine control module (ECM) is unable to communicate with the transmission control module, potentially leading to transmission shifting problems, limp mode, or other drivability issues. Another example is U1000, which is a general communication bus fault and can indicate a widespread communication problem within the vehicle’s network. Diagnosing network communication codes often requires specialized tools and expertise to trace the communication fault and identify the root cause.

Understanding these four main categories of OBD2 codes – Powertrain, Body, Chassis, and Network Communication – is crucial for effectively interpreting engine codes and other diagnostic information. This knowledge empowers vehicle owners and fleet managers to approach diagnostics more strategically and efficiently.

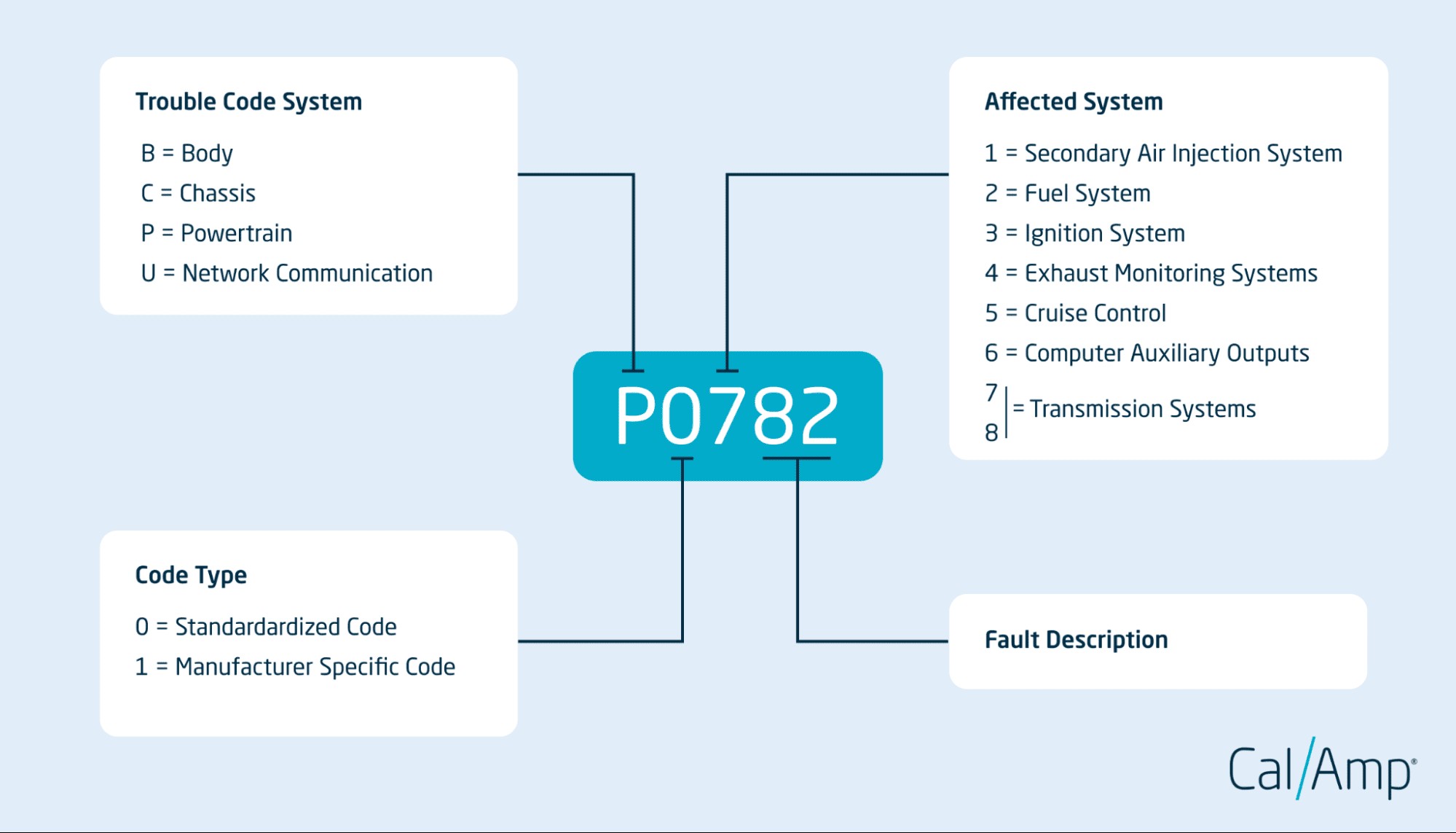

Reading OBD2 Codes: Deciphering the Diagnostic Message

OBD2 codes are structured in a five-character format, combining letters and numbers, each position holding specific meaning. Understanding this structure is key to interpreting the diagnostic message conveyed by the code.

What OBD2 codes mean

What OBD2 codes mean

Let’s break down each position to understand how to read OBD-II codes meaning:

-

First Character: Trouble Code System: This letter indicates the primary system affected.

- P: Powertrain (Engine, Transmission, Drivetrain)

- B: Body (Airbags, Climate Control, Comfort/Convenience Systems)

- C: Chassis (Brakes, Suspension, Steering)

- U: Network Communication (Communication Bus Issues)

-

Second Character: Code Type: This digit specifies whether the code is generic or manufacturer-specific.

- 0: Generic or Standardized Code (SAE standard, common to all manufacturers)

- 1: Manufacturer-Specific Code (Specific to a particular vehicle manufacturer)

-

Third Character: Affected System: This digit represents the specific subsystem affected. The categories generally are:

- 1: Fuel and Air Metering

- 2: Fuel and Air Metering (Injector Circuit Malfunction)

- 3: Ignition System or Misfire

- 4: Auxiliary Emission Controls

- 5: Vehicle Speed Controls and Idle Control System

- 6: Computer Output Circuit

- 7: Transmission

- 8: Transmission

-

Fourth and Fifth Characters: Specific Code: These two digits are sequential numbers that further pinpoint the specific fault within the identified system and subsystem. For example, in the code P0420, “420” specifies “Catalyst System Efficiency Below Threshold (Bank 1).”

By understanding this structure, you can begin to interpret diagnostic trouble codes more effectively. For instance, a code like “C0121” can be decoded as follows:

- C: Chassis system

- 0: Generic code

- 1: Fuel and Air Metering (While seemingly contradictory to “Chassis,” in this context, it relates to ABS system functionality which can involve fuel/air system interaction indirectly for engine control during braking)

- 21: Specific fault related to ABS Valve Relay Circuit Malfunction

While generic codes (indicated by ‘0’ in the second position) are standardized across all vehicles, manufacturer-specific codes (indicated by ‘1’) provide more detailed diagnostics unique to a particular make or model. When dealing with manufacturer-specific codes, consulting a vehicle-specific repair manual or database is often necessary for accurate interpretation. Utilizing an OBD-II code reader will display these codes, and understanding this structure allows for a more informed approach to vehicle diagnostics and repair.

Clearing OBD2 Codes: When and How

Clearing OBD2 codes is a function available on most OBD2 scanners. However, it’s crucial to understand when and why you should clear codes, and when it’s best left to a professional. While it might be tempting to clear a code and make the check engine light disappear, doing so without addressing the underlying issue is generally not advisable.

When Clearing Codes Might Be Appropriate

- After Repair: Once you have diagnosed the problem indicated by the OBD2 code and completed the necessary repairs, clearing the code is a standard step. This resets the system and turns off the check engine light. If the repair was successful, the code should not reappear.

- False Positives (Rare): In rare cases, a code might be triggered by a temporary sensor glitch or anomaly. If you suspect a false positive, you can clear the code and see if it returns. However, if the code reappears, it should be investigated as a genuine issue.

- Verification of Repair: After performing a repair, clearing the code and then performing a drive cycle can help verify if the repair was effective. If the code does not return after the drive cycle, it indicates the issue is likely resolved.

Methods for Clearing OBD2 Codes

-

Using an OBD2 Scanner: This is the most common and reliable method.

- Connect the OBD2 scanner to your vehicle’s OBD2 port.

- Turn the vehicle’s ignition to the “ON” position (engine off).

- Navigate the scanner’s menu to find the “Clear Codes” or “Erase Codes” function.

- Follow the scanner’s prompts to clear the codes.

- After clearing, start the engine and check if the check engine light remains off.

-

Drive Cycle: Some codes, particularly those related to emissions, might clear themselves after a series of successful drive cycles if the fault condition is no longer present. A drive cycle typically involves specific driving conditions (speed, duration, engine temperature) that allow the vehicle’s computer to re-evaluate the system. However, this method is not reliable for all codes and can take time.

-

Disconnecting the Battery (Caution Advised): Disconnecting the negative battery terminal for a period (typically 10-15 minutes) can reset the vehicle’s computer and clear stored OBD2 codes. However, this method should be used with caution as it can also reset other vehicle systems, such as radio presets, security systems, and require you to re-enter radio security codes in some vehicles. It is generally preferable to use an OBD2 scanner for code clearing.

When to Consult a Mechanic Instead of Clearing Codes

- Uncertainty about the Problem: If you are unsure about the cause of the OBD2 code or lack the expertise to diagnose and repair the issue, it’s best to consult a qualified mechanic.

- Recurring Codes: If you clear a code and it quickly reappears, it indicates a persistent problem that needs professional diagnosis and repair. Repeatedly clearing codes without addressing the root cause can mask underlying issues and potentially lead to more serious damage.

- Serious Symptoms: If the OBD2 code is accompanied by noticeable vehicle performance issues like rough running, stalling, unusual noises, or warning lights beyond the check engine light, seek professional help immediately.

Clearing car repair codes should be done responsibly and with an understanding of the potential implications. For fleet managers, it’s crucial to establish a protocol for OBD2 code handling that prioritizes proper diagnosis and repair over simply clearing codes to temporarily silence warnings.

Preventing OBD2 Codes: Proactive Vehicle Maintenance

Preventing OBD2 codes is far more efficient and cost-effective than dealing with repairs after codes appear. Proactive vehicle maintenance is key to minimizing the occurrence of OBD2 codes and ensuring the longevity and reliability of your vehicles, especially for fleet operations.

Regular Vehicle Maintenance: The Foundation of Prevention

Regular maintenance, adhering to the manufacturer’s recommended service schedule, is the most effective way to prevent OBD2 codes. This includes:

- Oil Changes: Regular oil changes with the correct type of oil are crucial for engine lubrication and preventing engine-related codes. Dirty or low oil can lead to various engine problems and trigger codes.

- Fluid Checks and Flushes: Regularly check and replenish fluids such as coolant, brake fluid, power steering fluid, and transmission fluid. Scheduled fluid flushes (e.g., coolant flush, transmission fluid change) at recommended intervals prevent fluid degradation and system malfunctions that can trigger OBD2 codes.

- Air Filter Replacement: A clean air filter ensures proper airflow to the engine. A clogged air filter can reduce engine performance and fuel efficiency and potentially trigger codes related to fuel trim or airflow.

- Spark Plug and Ignition System Maintenance: Regularly inspect and replace spark plugs and other ignition components (wires, coils) as needed. Worn spark plugs can cause misfires, a common cause of powertrain codes.

- Brake System Inspections: Regular brake inspections, including pads, rotors, and brake lines, ensure brake system integrity and prevent chassis codes related to ABS or brake performance.

- Tire Rotations and Inspections: Regular tire rotations promote even tire wear, and inspections can identify tire issues that might indirectly affect systems monitored by OBD2, such as ABS or stability control.

- Exhaust System Inspections: Periodically inspect the exhaust system for leaks or damage, which can lead to emissions-related codes.

By consistently performing these routine maintenance tasks, you address potential issues before they escalate and trigger OBD2 codes, reducing the likelihood of unexpected breakdowns and costly repairs.

Using Quality Fuel and Fluids: Protecting Vehicle Systems

The quality of fuel and fluids you use significantly impacts vehicle health and the likelihood of OBD2 codes.

- High-Quality Fuel: Use fuel from reputable sources and adhere to the manufacturer’s recommended octane rating. Low-quality fuel can lead to incomplete combustion, causing engine deposits, reduced fuel efficiency, and emissions problems, all of which can trigger OBD2 codes.

- Manufacturer-Recommended Fluids: Always use fluids (engine oil, transmission fluid, coolant, brake fluid, power steering fluid) that meet or exceed the vehicle manufacturer’s specifications. Using incorrect or low-quality fluids can compromise lubrication, cooling, and system performance, leading to premature wear and OBD2 codes.

- Regular Fluid Level Checks: Periodically check fluid levels and top them off as needed. Low fluid levels can lead to system overheating, pump failures, and other issues that trigger diagnostic codes.

Addressing Issues Promptly: Preventing Escalation

When you notice any unusual vehicle behavior – such as strange noises, leaks, changes in performance, or warning lights – address them promptly. Ignoring minor issues can allow them to worsen over time, eventually triggering OBD2 codes and potentially leading to more extensive and expensive repairs. Early intervention is always more cost-effective and helps prevent the escalation of problems.

For fleet managers, implementing a robust preventative maintenance program and emphasizing the use of quality consumables are essential strategies for minimizing OBD-II codes and maintaining fleet uptime and operational efficiency.

Managing OBD2 Codes for Your Fleet: Streamlining Diagnostics and Maintenance

For fleet managers, efficiently managing OBD2 codes across a fleet of vehicles is crucial for minimizing downtime, controlling maintenance costs, and ensuring operational continuity. Implementing standardized and streamlined processes for handling OBD2 codes is essential.

Centralized OBD2 Code Tracking and Management

Utilizing a centralized system for tracking and managing OBD2 codes across your fleet provides significant advantages. Modern fleet management software, often integrated with telematics systems, can automatically collect and centralize OBD2 code data from all connected vehicles.

- Real-Time Code Alerts: These systems provide real-time alerts when OBD2 codes are triggered in any vehicle within the fleet, enabling immediate awareness of potential issues.

- Centralized Dashboard: A centralized dashboard displays all active and historical OBD2 codes, allowing fleet managers to quickly identify trends, recurring issues, and prioritize maintenance tasks.

- Reporting and Analytics: Robust reporting features enable analysis of OBD2 code data to identify common problems across the fleet, track maintenance effectiveness, and optimize preventative maintenance schedules.

- Integration with Maintenance Scheduling: Centralized systems can integrate with maintenance scheduling tools, automatically triggering work orders or maintenance requests based on OBD2 code severity and vehicle priority.

Proactive Fleet Monitoring with Telematics

Telematics systems offer continuous monitoring of vehicle health, going beyond just OBD2 codes. They provide a wealth of real-time data, including:

- Vehicle Location and Usage: Track vehicle location, mileage, engine hours, and driving patterns, providing context for OBD2 code analysis and maintenance planning.

- Performance Metrics: Monitor engine parameters, fuel consumption, battery voltage, and other performance metrics that can indicate potential problems before OBD2 codes are even triggered.

- Predictive Maintenance Capabilities: Advanced telematics systems can analyze historical data and real-time metrics to predict potential component failures and schedule preventative maintenance proactively, further reducing the occurrence of OBD2 codes and unexpected breakdowns.

Prioritizing Repairs Based on Code Severity and Impact

Not all OBD2 codes are created equal. Implementing a system for prioritizing repairs based on code severity and potential impact on operations is crucial for efficient resource allocation.

- Severity Classification: Categorize OBD2 codes based on their severity – high (immediate attention needed), medium (address soon), and low (schedule for routine maintenance). High-severity codes might include those related to safety-critical systems (brakes, airbags) or major engine/transmission issues that could lead to vehicle breakdown.

- Impact Assessment: Consider the operational impact of each code. A code on a vehicle critical to daily operations might require higher priority than a code on a less frequently used vehicle.

- Workflow for Code Handling: Establish a clear workflow for handling OBD2 codes, including steps for code notification, diagnosis, repair authorization, scheduling, and verification.

By implementing these strategies, fleet managers can transform OBD2 codes from reactive problem indicators into proactive maintenance triggers, improving fleet reliability, reducing costs, and optimizing vehicle uptime.

In Summary: Leveraging OBD2 Codes for Vehicle Health

OBD2 codes are an invaluable diagnostic tool, providing insights into your vehicle’s health and alerting you to potential issues. Understanding codes for OBD2, their types, and how to interpret them is essential for both individual vehicle owners and fleet managers.

While an OBD-II code reader is helpful for retrieving codes, a comprehensive approach to OBD2 management, especially for fleets, involves proactive prevention, centralized tracking, and efficient repair prioritization. By embracing regular maintenance, utilizing quality consumables, and leveraging telematics systems for fleet monitoring, you can minimize the occurrence of OBD2 codes, ensure vehicle longevity, and optimize operational efficiency.

For fleet operations seeking advanced OBD2 code management and vehicle health monitoring, solutions like CalAmp iOn offer a comprehensive platform for real-time insights, centralized data, and proactive maintenance scheduling. Understanding and effectively utilizing OBD2 codes is a cornerstone of modern vehicle maintenance and fleet management, enabling informed decisions and proactive vehicle care.