For vehicle owners and fleet managers alike, understanding the health of your vehicles is paramount. Staying ahead of potential engine problems and other malfunctions is not only crucial for driver safety but also for preventing costly repairs down the line. This is where Obd2 Dtc Codes come into play – a standardized system of codes used by your vehicle’s onboard computer to signal potential issues.

But what exactly are these codes, and how do you decipher them? More importantly, how can you leverage this information to maintain your vehicle or even manage an entire fleet efficiently?

In this guide, we will delve deep into the world of OBD2 DTC codes. We’ll explain what they are, how to interpret them, and how understanding these codes can empower you to take proactive steps in vehicle maintenance and repair. Whether you’re a car enthusiast, a fleet manager, or simply a vehicle owner wanting to understand your car better, this comprehensive guide will equip you with the knowledge you need to navigate the complexities of OBD2 diagnostic trouble codes.

What are OBD2 DTC Codes?

DTC stands for Diagnostic Trouble Codes. These codes are standardized alphanumeric identifiers generated by a vehicle’s On-Board Diagnostics (OBD) system. The system itself, and specifically the OBD-II standard we’re focusing on here, was developed to monitor various systems within your vehicle and alert you to potential malfunctions. The Society of Automotive Engineers (SAE) established these standards to ensure consistency across vehicle manufacturers. Each character in a 5-digit OBD2 DTC code is designed to pinpoint a specific area or type of problem within the vehicle.

The OBD-II standard is the most prevalent and relevant for most drivers. Here’s what you need to know:

- OBD-II Standard: This is the standard mandated for all light-duty vehicles (weighing between 6,000 to 10,000 lbs) and medium-duty vehicles (10,001 to 26,000 lbs) sold in the United States after January 1, 1996. So, if you own a car, SUV, or light truck manufactured after 1996 in the US, it’s almost certainly OBD-II compliant.

While OBD-II is the standard for lighter vehicles, it’s worth noting there’s another standard for heavier vehicles:

- J1939 Standard: This standard is used for heavy-duty vehicles (26,001 to over 33,000 lbs), such as large trucks, buses, and heavy equipment. While we are focusing on OBD2 DTC codes, understanding that J1939 exists for heavy-duty applications provides a broader context.

It’s also important to be aware that manufacturers can have their own, manufacturer-specific DTC codes in addition to the standard OBD2 codes. If you encounter a code that seems unusual or isn’t readily explained by generic OBD2 resources, consulting your vehicle’s user manual or a manufacturer-specific repair guide is advisable.

The most common way you’ll encounter an OBD2 DTC code is when your vehicle’s check engine light (also known as the malfunction indicator light or MIL) illuminates on the dashboard. When this light comes on, it signals that the OBD-II system has detected an issue and stored a corresponding DTC code. To access this code, a technician typically uses a handheld OBD2 scanner. This scanner plugs into the vehicle’s diagnostic port, usually located under the dashboard on the driver’s side, beneath the steering wheel. Once connected, the scanner reads and displays the stored DTC code, providing a starting point for diagnosing the problem.

P04020 DTC code

P04020 DTC code

Using an OBD2 scanner directly requires physical access to the vehicle. However, for fleet management and even personal vehicle monitoring, advancements in technology offer remote solutions. Modern telematics systems can connect to a vehicle’s OBD-II system and transmit DTC codes and other vehicle data wirelessly. This allows fleet managers to receive real-time alerts whenever a vehicle in their fleet generates a DTC code, enabling proactive maintenance and issue resolution.

Decoding OBD2 DTC Codes: A Step-by-Step Guide

When an OBD2 DTC code appears, understanding its structure is key to deciphering the problem. Each OBD2 DTC code is composed of five characters, and each character provides vital information. Let’s break down the anatomy of an OBD2 DTC code:

First Character: The Letter – System Identification

The very first character of an OBD2 DTC code is always a letter, and this letter immediately tells you which major vehicle system is affected. There are four primary categories:

-

P Codes (Powertrain): “P” codes are the most common, indicating an issue within the powertrain system. This broad category includes the engine, transmission, fuel system, ignition system, emission control system, and drivetrain components. Powertrain issues are often directly related to engine performance and efficiency.

-

C Codes (Chassis): “C” codes signal problems with the chassis systems. The chassis encompasses mechanical systems outside of the main body and powertrain. This includes steering, suspension, anti-lock braking system (ABS), and traction control. Chassis codes often relate to vehicle handling, stability, and braking performance.

-

B Codes (Body): “B” codes point to issues within the vehicle’s body systems. These systems are generally located within the passenger compartment and include components like power windows, power seats, air conditioning, airbags, and central locking. Body codes can relate to comfort, convenience, and safety features within the vehicle’s cabin.

-

U Codes (Network/Communication): “U” codes are related to communication and network issues within the vehicle’s onboard computer systems. Modern vehicles have complex networks connecting various electronic control units (ECUs). “U” codes can indicate problems with communication between these modules, or with the OBD system itself. These are often more complex electrical or software-related issues.

Second Character: The Digit – Code Type

The second character in an OBD2 DTC code is a numeric digit, and it specifies the code type, differentiating between standardized and manufacturer-specific codes:

-

0 (Generic/Standardized): A “0” in the second position indicates a generic OBD2 code, also known as a SAE international code. Generic codes are standardized across all vehicle makes and models that comply with the OBD-II standard. This means a P0 code from a Ford will generally have the same meaning as a P0 code from a Toyota, making diagnosis more universal.

-

1 (Manufacturer-Specific/Enhanced): A “1” in the second position signifies a manufacturer-specific or enhanced code. These codes are defined by the vehicle manufacturer and are not part of the generic OBD-II standard. They often relate to more specific or advanced systems within a particular make or model. If you encounter a code with “1” as the second character, consulting a repair manual specific to your vehicle’s make and model is highly recommended.

Third Character: The Digit – Subsystem Identification

If the second character is “0” (indicating a generic code), the third character, which is also a digit, further refines the problem area by specifying the subsystem within the broader system identified by the first character. Here’s a breakdown of the subsystems represented by the third digit:

-

0: Fuel and Air Metering & Auxiliary Emission Controls: Codes starting with “P00xx” often relate to issues with the mass airflow sensor (MAF), oxygen sensors, fuel trim, and other components involved in regulating the fuel-air mixture and managing emissions.

-

1: Fuel and Air Metering (Injection System): Codes starting with “P01xx” are more specifically focused on the fuel injection system itself, including fuel injectors, fuel pressure regulators, and related sensors.

-

2: Fuel and Air Metering (Injection System): Codes starting with “P02xx” also relate to the fuel and air metering and injection system, often indicating issues in different areas of the system compared to “P01xx” codes, or potentially more severe problems.

-

3: Ignition Systems or Misfires: Codes starting with “P03xx” are centered around ignition system malfunctions, most commonly misfires. These codes can pinpoint issues with spark plugs, ignition coils, distributor (in older vehicles), and crankshaft/camshaft position sensors.

-

4: Auxiliary Emission Controls: Codes starting with “P04xx” relate to auxiliary emission control devices beyond the primary catalytic converter, such as evaporative emission control systems (EVAP), secondary air injection systems, and exhaust gas recirculation (EGR) systems.

-

5: Vehicle Speed Control, Idle Control Systems, & Auxiliary Inputs: Codes starting with “P05xx” cover a range of systems including vehicle speed sensors, idle air control valves, cruise control, and other auxiliary inputs to the engine control unit (ECU).

-

6: Computer Output Circuit: Codes starting with “P06xx” typically indicate problems within the ECU itself or its output circuits. These can be more complex electrical or internal ECU failures.

-

7 & 8: Transmission: Codes starting with “P07xx” and “P08xx” are dedicated to transmission-related issues when the powertrain code “P” is used. These can range from transmission fluid temperature sensors to shift solenoid malfunctions and more serious internal transmission problems.

Fourth and Fifth Characters: The Digits – Specific Fault Index

The final two characters of an OBD2 DTC code are digits ranging from 00 to 99. These two digits, known as the Specific Fault Index, provide the most granular level of detail, identifying the precise malfunction within the subsystem indicated by the preceding characters. For example, within the “P04xx” category (Auxiliary Emission Controls), a “P0420” specifically points to a problem with the catalytic converter efficiency, as we’ll see in the example below.

OBD2 DTC Code Example: P0420 – Catalytic Converter Efficiency Below Threshold

Let’s put all this together and break down a common OBD2 DTC code: P0420.

P04020 DTC code

P04020 DTC code

- P: Indicates a Powertrain issue, meaning the problem is related to the engine, transmission, or emissions system.

- 0: Signifies a generic OBD2 code, applicable to all OBD-II compliant vehicles.

- 4: Points to the Auxiliary Emission Controls subsystem as the area of concern.

- 20: The Specific Fault Index “20” pinpoints the exact issue: Catalytic Converter System Efficiency Below Threshold (Bank 1).

Therefore, a P0420 code clearly indicates that the vehicle’s catalytic converter (specifically Bank 1, if applicable to the engine configuration) is not operating at the expected efficiency level. This could be due to a failing catalytic converter, but also potentially related to issues with oxygen sensors, exhaust leaks, or engine performance problems that are impacting the catalytic converter’s function. It’s definitely a code that requires attention and further diagnosis to determine the root cause and necessary repair.

Beyond OBD2: Understanding J1939 DTC Codes for Heavy-Duty Vehicles

While OBD2 DTC codes are the standard for most cars and light/medium-duty trucks, it’s important to briefly touch upon J1939 DTC codes if you are involved with heavy-duty vehicles. SAE J1939 is the industry-standard communication protocol for diagnostics and control data in heavy-duty vehicles, including large trucks, buses, construction equipment, and agricultural machinery.

J1939 codes have a different structure than OBD2 codes, consisting of four key fields that provide diagnostic information:

-

Suspect Parameter Number (SPN): The SPN is a numeric code assigned by the SAE to identify a specific component or electrical subsystem that has a fault. It’s the core identifier of what is malfunctioning. SPNs help technicians quickly locate the general area of the problem.

-

Failure Mode Identifier (FMI): The FMI is a code that specifies the type of fault detected for the SPN. FMIs describe the nature of the error, such as “data erratic, intermittent, or incorrect,” “sensor circuit shorted to ground,” “mechanical system not responding or out of adjustment,” etc. The FMI provides crucial context to the SPN.

-

Occurrence Counter (OC): The OC is a counter that tracks how many times a particular fault (SPN and FMI combination) has occurred. It increments each time the same error is detected. This can help in diagnosing intermittent problems and understanding the frequency of an issue.

-

SPN Conversion Method (CM): The CM field defines the byte alignment within the DTC message and specifies how the SPN and FMI should be interpreted, especially in older J1939 implementations. It’s less critical for day-to-day diagnostics but is relevant for understanding the technical protocol.

Traditionally, accessing J1939 DTC codes often involved using specialized J1939 data loggers directly connected to the vehicle. However, just like with OBD2, modern telematics solutions for heavy-duty fleets can interface with the J1939 network, enabling remote access to DTCs and other critical vehicle data. This allows fleet managers to monitor the health of their heavy-duty vehicles in real-time, receive alerts for engine faults, and proactively schedule maintenance, minimizing downtime and repair costs.

Clearing OBD2 DTC Codes: When and How to Do It

Seeing the check engine light illuminate can be concerning, and naturally, you might wonder about clearing the DTC code after addressing the underlying issue. Here’s what you need to know about clearing OBD2 DTC codes:

Using an OBD2 Code Reader to Clear Codes

For vehicles manufactured after 1996 in the US, you can use an OBD2 scanner not only to read DTC codes but also often to clear them. Here’s the process:

-

Diagnose and Repair: Crucially, you should only attempt to clear a DTC code after you have diagnosed and repaired the underlying problem that triggered the code in the first place. Clearing the code without fixing the issue is like turning off a fire alarm without putting out the fire – the problem will likely return, and potentially worsen.

-

Connect the Scanner: Plug your OBD2 scanner into the vehicle’s diagnostic port (usually under the steering wheel).

-

Turn Ignition ON, Engine OFF: Turn the ignition key to the “ON” position, so the vehicle’s electrical systems are active, but do not start the engine.

-

Read Codes (Optional but Recommended): Even if you’ve already read the code, it’s good practice to read the codes again with the scanner to confirm the code is still present before attempting to clear it.

-

Clear Codes: Navigate to the “Clear Codes,” “Erase Codes,” or similar function on your OBD2 scanner and follow the prompts. The scanner will send a command to the vehicle’s computer to clear the stored DTC code and turn off the check engine light.

-

Verify Clearance: After clearing, turn the ignition off and then back on. The check engine light should be off. You can also re-scan for codes to confirm that the DTC has been cleared.

Important Considerations When Clearing Codes:

-

Temporary Fix Only if Underlying Issue Persists: Clearing a code does not fix the underlying problem. If the issue is not properly repaired, the check engine light and the DTC code will almost certainly return, sometimes very quickly.

-

Drive Cycles and Readiness Monitors: After clearing codes, the vehicle’s OBD-II system needs to run a series of self-tests called “drive cycles” to ensure that the repaired system is functioning correctly. These drive cycles test various systems and set “readiness monitors” to indicate whether the systems have passed their tests. It may take several drive cycles for all readiness monitors to be set to “ready.” This is particularly important for emissions testing, as many jurisdictions require readiness monitors to be set before a vehicle can pass.

-

Potential Loss of Data: Clearing DTC codes may also clear other temporary data stored in the vehicle’s computer, such as fuel trim data or learned settings. In most cases, this is not a major concern, but it’s something to be aware of.

When to Seek Professional Repairs Instead of Clearing Codes

While clearing codes yourself after a confirmed repair can be acceptable for minor issues, there are definitely situations where professional diagnosis and repair are essential:

-

Flashing Check Engine Light: A flashing check engine light typically indicates a more serious and potentially urgent problem, such as an engine misfire that could damage the catalytic converter. In these cases, it’s best to pull over safely as soon as possible and have the vehicle towed to a qualified mechanic. Do not attempt to clear the code and continue driving with a flashing check engine light.

-

Persistent Codes: If a DTC code returns immediately or very soon after you clear it, even after attempting a repair, this indicates that the underlying problem is still present or that your repair was not effective. Professional diagnosis is needed to pinpoint the root cause.

-

Codes You Don’t Understand: If you are unsure about the meaning of a DTC code, or if it relates to a complex system you are not comfortable working on, it’s always best to consult a qualified mechanic. Guessing at repairs based on a DTC code can lead to further problems and unnecessary expenses.

-

Permanent DTCs: Some vehicle issues may trigger “permanent DTCs.” Unlike regular DTCs, permanent DTCs cannot be cleared with a standard OBD2 scanner or by disconnecting the battery. They are designed to remain until the vehicle’s onboard system confirms that the underlying issue has been resolved through drive cycles. Permanent DTCs are primarily relevant to emissions-related faults. They will clear automatically once the system passes its self-tests after a proper repair.

Common Check Engine Light Repairs

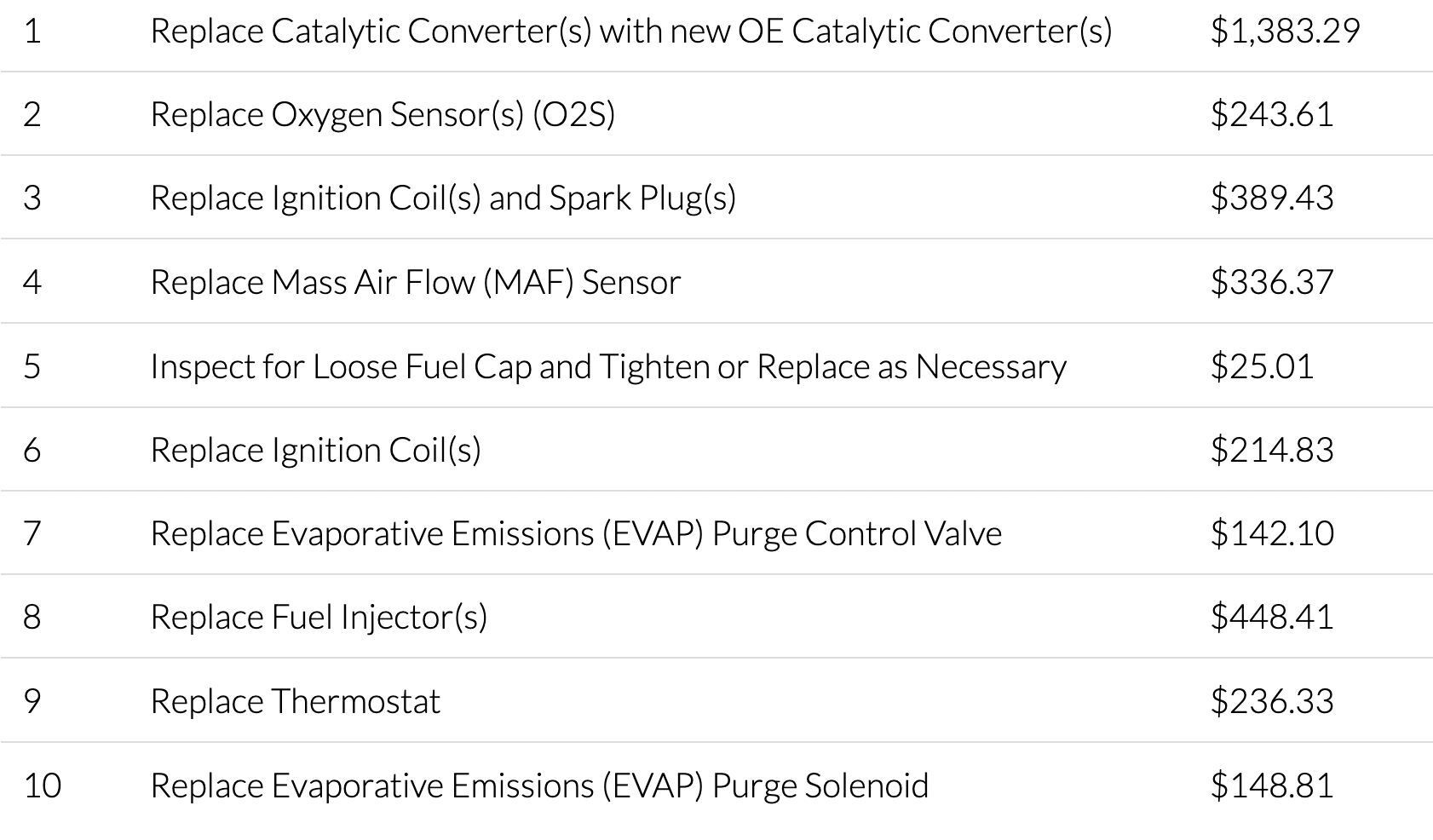

CarMD has compiled data on the most common check engine light repairs in the US, providing insights into typical issues and their estimated costs:

Most common check engine vehicle repairs in the US

Most common check engine vehicle repairs in the US

This data highlights that issues like catalytic converter replacement, oxygen sensor replacement, and ignition coil/spark plug replacement are frequently encountered check engine light repairs. Understanding these common issues can help you anticipate potential problems and budget for maintenance.

Managing OBD2 DTC Codes for Fleets with Telematics Systems

For fleet managers overseeing multiple vehicles, efficiently monitoring and managing OBD2 DTC codes is critical for maintaining operational efficiency, minimizing downtime, and controlling maintenance costs. Traditional handheld scanners are impractical for fleet-wide monitoring. This is where fleet telematics systems provide a powerful solution.

Telematics systems offer a range of benefits for managing OBD2 DTC codes in a fleet environment:

Real-Time DTC Alerts and Notifications

A key advantage of telematics is the ability to receive real-time alerts whenever a vehicle in your fleet generates an OBD2 DTC code. These alerts are typically transmitted wirelessly to a fleet management dashboard or mobile app, providing immediate notification of potential issues. The alerts usually include the specific DTC code and a description of the fault.

This real-time notification allows fleet managers to:

- Respond Proactively: Instead of waiting for scheduled maintenance or driver reports, managers are immediately aware of problems.

- Assess Severity Quickly: The DTC code and description provide initial information to assess the seriousness of the issue. Is it a minor sensor fault or a potentially engine-damaging problem?

- Direct Drivers Efficiently: Based on the DTC and vehicle location data from the telematics system, managers can direct drivers to the nearest service station or advise them on appropriate actions. They can also coordinate vehicle swaps if needed to keep operations running smoothly.

Automated Fleet Maintenance Scheduling and Reminders

Telematics systems can also streamline fleet maintenance by automating scheduling and reminders based on vehicle usage and DTC codes. Features include:

- Mileage-Based and Hour-Based Scheduling: Maintenance schedules can be set based on vehicle mileage, engine hours, or calendar intervals for routine tasks like oil changes, tire rotations, and inspections.

- DTC-Triggered Maintenance: Certain DTC codes can automatically trigger maintenance requests or schedule inspections. For example, a recurring code related to engine misfires might prompt an immediate inspection of the ignition system.

- Maintenance History Tracking: Telematics systems maintain a digital record of all maintenance performed on each vehicle, including DTC events, repairs, and service dates. This history helps in tracking trends, identifying vehicles with recurring problems, and optimizing maintenance intervals.

DTC Reports and Fleet Health Analysis

Telematics platforms provide robust reporting capabilities that enable fleet managers to analyze DTC data across their entire fleet. This data-driven approach to maintenance offers several benefits:

- Identify Common Issues and Trends: Reports can highlight frequently occurring DTC codes across the fleet. This can reveal common component failures, wear patterns, or even potential issues related to driving habits or operating conditions.

- Optimize Maintenance Strategies: By understanding common failure points, fleet managers can proactively adjust maintenance schedules, stock commonly needed parts, and implement preventative maintenance programs to address recurring issues before they lead to breakdowns.

- Measure Fleet Health and Performance: DTC reports provide a quantifiable measure of fleet health. Tracking the frequency and severity of DTC events over time can help assess the overall condition of the fleet and the effectiveness of maintenance efforts.

By leveraging telematics for OBD2 DTC code management, fleet operations can achieve:

- Reduced Downtime: Proactive alerts and faster response times minimize vehicle downtime due to breakdowns and repairs.

- Lower Maintenance Costs: Preventative maintenance, optimized scheduling, and early issue detection help avoid costly repairs and extend vehicle lifespan.

- Improved Driver Safety: Addressing vehicle problems promptly ensures vehicles are safe to operate, reducing risks for drivers and cargo.

- Increased Operational Efficiency: A healthier, better-maintained fleet translates to smoother operations, improved vehicle availability, and enhanced customer satisfaction.

Conclusion

Understanding OBD2 DTC codes is no longer just for mechanics; it’s valuable knowledge for any vehicle owner and essential for fleet managers. These codes are the language your vehicle uses to communicate potential problems, ranging from minor issues to serious malfunctions.

While handheld OBD2 scanners are useful for individual vehicle diagnostics, fleet telematics systems represent a significant advancement for managing DTC codes across a fleet. They provide real-time alerts, automate maintenance scheduling, and offer powerful reporting tools that enable proactive maintenance, reduced downtime, and improved fleet efficiency.

By mastering the basics of OBD2 DTC codes and embracing the power of telematics, you can take control of your vehicle’s health, minimize unexpected repairs, and ensure your fleet operates smoothly and safely. To learn more about how fleet telematics can revolutionize your fleet management, explore solutions like CalAmp iOn and contact us today to discover how we can help you optimize your fleet operations.