Understanding your vehicle’s health is becoming increasingly accessible, thanks to On-Board Diagnostics (OBD2) systems. At the heart of OBD2 are Parameter IDs, or PIDs. This guide will delve into Obd2 Pids, explaining what they are, how they work, and why they are crucial for modern vehicle diagnostics. We’ll provide a comprehensive overview, enhanced for clarity and SEO, making it your go-to resource for mastering OBD2 PIDs.

OBD2 is a standardized system in vehicles that allows you to access real-time data about your car’s performance and health. It’s like having a direct line to your vehicle’s computer, providing insights into various parameters from engine temperature to vehicle speed. OBD2 PIDs are the codes used to request this specific data. Think of them as addresses to different sensors and systems within your car. By sending a specific PID request, you can receive a response containing the corresponding sensor data.

J1939 data pack

J1939 data pack

Decoding OBD2 PIDs: Requests and Responses

Communication with your vehicle’s OBD2 system happens through a Controller Area Network (CAN bus). To retrieve data, tools like OBD2 scanners or interfaces send ‘OBD2 requests’ as CAN frames. These requests are directed to the vehicle’s Electronic Control Unit (ECU) via the OBD2 port, typically located under the dashboard.

A standard OBD2 request uses a specific CAN ID and data payload structure. For instance, to request the Vehicle Speed PID (PID 0D), an OBD2 tool sends a CAN frame with the ID 7DF and a data payload like 02 01 0D 55 55 55 55 55. Let’s break this down:

- CAN ID

7DF: This is the standard broadcast address for OBD2 requests. - Data Payload

02 01 0D 55 55 55 55 55:02: Indicates the number of bytes following, excluding the CAN ID and this byte itself.01: Specifies the service ID for “Show Current Data”.0D: This is the OBD2 PID for Vehicle Speed.55 55 55 55 55: Padding bytes, often used to fill the remaining data bytes.

Upon receiving a valid request for a supported PID, the vehicle’s ECU will respond with an ‘OBD2 response’ frame on the CAN bus. The response CAN ID is typically 7E8 or within the range of 7E8 to 7EF, depending on the ECU address. The data payload of the response contains the requested PID value.

For example, a response to the Vehicle Speed PID request might look like this: 7E8 03 41 0D XX AA AA AA AA.

- CAN ID

7E8: Response CAN ID from the ECU. - Data Payload

03 41 0D XX AA AA AA AA:03: Number of data bytes following.41: Response service ID, acknowledging service01request.0D: Echoes the requested PID (Vehicle Speed) for confirmation.XX: Two hexadecimal digits representing the vehicle speed value.AA AA AA AA: Padding bytes.

The value XX in the response is the hexadecimal representation of the vehicle speed in km/h. To get the decimal value, you would convert XX from hexadecimal to decimal.

OBD2 PID Table: Understanding Service 01 Parameters

OBD2 PIDs are standardized by SAE J1979, ensuring consistency across different vehicle makes and models. Service 01 is particularly important as it deals with “Show Current Data,” providing real-time sensor readings. The following table outlines common OBD2 PIDs within Service 01, along with essential details for decoding the data:

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 00 | PIDs supported [01 – 20] | 31 | 32 | 1 | 0 | Encoded | ||

| 1 | 01 | Monitor status since DTCs cleared | 31 | 32 | 1 | 0 | Encoded | ||

| 2 | 02 | Freeze DTC | 31 | 16 | 1 | 0 | Encoded | ||

| 3 | 03 | Fuel system status | 31 | 16 | 1 | 0 | Encoded | ||

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 6 | 06 | Short term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 7 | 07 | Long term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 8 | 08 | Short term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 9 | 09 | Long term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 10 | 0A | Fuel pressure (gauge pressure) | 31 | 8 | 3 | 0 | 0 | 765 | kPa |

| 11 | 0B | Intake manifold absolute pressure | 31 | 8 | 1 | 0 | 0 | 255 | kPa |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

| 14 | 0E | Timing advance | 31 | 8 | 0.5 | -64 | -64 | 64 | deg |

| 15 | 0F | Intake air temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 16 | 10 | Mass air flow sensor air flow rate | 31 | 16 | 0.01 | 0 | 0 | 655 | grams/sec |

| 17 | 11 | Throttle position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| … | … | … | … | … | … | … | … | … | … |

This table provides a structured way to understand and decode OBD2 PID data. Let’s illustrate with an example using Engine Speed (PID 0C).

Suppose you receive an OBD2 response payload for PID 0C as: 04 41 0C 0A 0C AA AA AA. According to the table:

- PID Hex:

0C - Name: Engine Speed

- Bit start: 31

- Bit length: 16

- Scale: 0.25

- Offset: 0

- Unit: rpm

The relevant data bytes in the response are 0A 0C. Since OBD2 uses big-endian byte order, we read these bytes as 0A0C in hexadecimal. Converting 0A0C from hex to decimal gives us 2572.

To calculate the physical Engine Speed value, we use the formula:

Physical Value = Offset + (Scale * Raw Decimal Value)Plugging in the values from the table and our example:

Engine Speed (rpm) = 0 + (0.25 * 2572) = 643 rpmTherefore, the engine speed is 643 revolutions per minute. This calculation method applies to most OBD2 PIDs that represent physical values. Some PIDs, however, are ‘encoded,’ meaning their values represent flags or statuses that require specific interpretation, as detailed in resources like the Wikipedia OBD2 PID list.

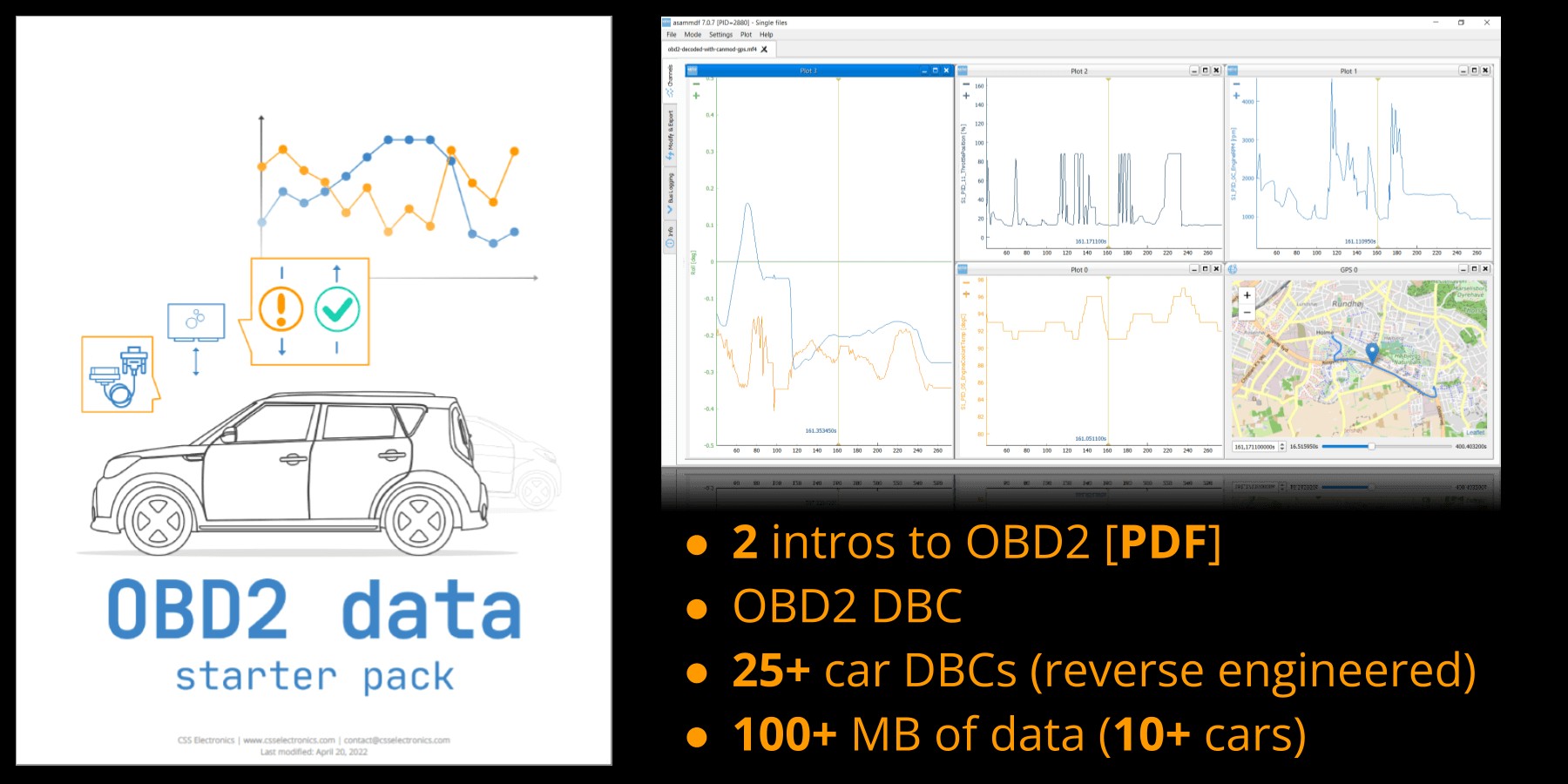

Programmatic Access to OBD2 PIDs: DBC and CSV Files

For developers and advanced users, accessing and decoding OBD2 PIDs programmatically is often necessary. This is where OBD2 DBC and CSV files become invaluable.

-

DBC (CAN Database) File: A DBC file for OBD2 PIDs provides a structured format readable by CAN bus software tools. It contains definitions for all common OBD2 PIDs, including their names, data types, scaling, and offsets. Using a DBC file with software tools simplifies the process of decoding raw CAN data containing OBD2 responses into human-readable values. This is particularly useful when working with OBD2 data loggers or interfaces.

-

CSV (Comma Separated Values) File: A CSV file offers a simpler, text-based format to store OBD2 PID information. It contains the same data as a DBC file but in a tabular format that is easily parsed by scripts or spreadsheet software. CSV files are excellent for implementing custom OBD2 PID decoding in scripts using languages like Python, allowing for flexible data processing and analysis.

Both DBC and CSV formats streamline the programmatic handling of OBD2 data, whether you’re developing a custom diagnostic tool, setting up a data logging system, or creating a telematics dashboard.

Advanced Applications: OBD2 Data Logging and Telematics

OBD2 PIDs are not just for diagnostics; they are the foundation for a wide range of advanced automotive applications:

-

OBD2 Data Logging: By recording OBD2 PID data over time, you can gain deep insights into vehicle performance under various driving conditions. This data is crucial for performance analysis, fuel efficiency studies, and diagnosing intermittent issues that might not trigger diagnostic trouble codes (DTCs). OBD2 data loggers capture CAN bus traffic, allowing for later analysis and decoding of PID values.

-

Telematics Dashboards: OBD2 data, accessed through PIDs, can be used to create real-time telematics dashboards. These dashboards visualize vehicle parameters like speed, engine load, temperature, and fuel consumption. This is valuable for fleet management, driver behavior monitoring, and creating custom displays for vehicle performance. Open-source APIs and tools are available to help build these dashboards, offering customizable and insightful visualizations.

Conclusion: Empowering Vehicle Understanding with OBD2 PIDs

OBD2 PIDs are the key to unlocking a wealth of information from your vehicle’s diagnostic system. Whether you are a mechanic diagnosing a fault, a car enthusiast monitoring performance, or a developer building automotive applications, understanding OBD2 PIDs is essential. This guide and the provided resources equip you with the knowledge to effectively utilize OBD2 PIDs for deeper vehicle insights and advanced automotive projects. Explore our OBD2 data pack and OBD2 data loggers to take your OBD2 expertise further.