For anyone delving into the world of vehicle diagnostics, “Obd2 Wikipedia” is often the starting search query. Wikipedia provides a foundational understanding of On-Board Diagnostics (OBD) systems, but let’s expand on that knowledge and explore the practical applications of OBD2, particularly in accessing real-time vehicle data. This article aims to go beyond a basic definition and delve into how OBD2 works and how enthusiasts and professionals are utilizing it.

What is OBD2? Unpacking On-Board Diagnostics

On-Board Diagnostics, specifically OBD2, is a standardized system implemented in most vehicles since the mid-1990s. As briefly outlined in resources like Wikipedia, its primary purpose is to monitor the performance of a vehicle’s engine and emissions systems. This system is crucial for both vehicle owners and automotive technicians. OBD2 tracks various parameters, from engine temperature and speed to oxygen sensor readings and fault codes. It acts as the car’s internal health monitor, alerting drivers to potential issues through the check engine light and providing detailed diagnostic trouble codes (DTCs) for mechanics.

The standardization of OBD2 is key. It ensures that regardless of the vehicle manufacturer, a universal diagnostic interface and a common set of codes are available. This standardization has revolutionized automotive repair, allowing for quicker and more accurate diagnoses. The OBD2 port, typically located within easy reach in the driver’s cabin, is the gateway to this wealth of vehicle information.

OBD2 and CAN Bus: The Communication Network

Modern OBD2 systems heavily rely on the Controller Area Network (CAN bus). CAN bus is a robust communication protocol that allows various electronic control units (ECUs) within a vehicle to communicate with each other without a central host computer. Think of it as the nervous system of your car, transmitting data between different parts. When you plug an OBD2 scanner into your car, it’s essentially tapping into this CAN bus network to request and receive data.

This data exchange is how diagnostic tools can read fault codes, monitor live engine parameters, and even send commands to certain vehicle systems (depending on the tool’s capabilities and security protocols). Understanding CAN bus is crucial for anyone wanting to go beyond basic OBD2 scanning and delve into custom data logging or vehicle modification.

Practical OBD2 Access: Learning from a Carloop Project

While theoretical knowledge about OBD2 and CAN bus is readily available, practical examples are invaluable. Consider a project focused on accessing OBD2 data using Carloop, a device that facilitates communication with a vehicle’s CAN bus. In a recent exploration, a user successfully tapped into their car’s CAN bus to retrieve OBD2 data by implementing specific code adjustments. This real-world scenario highlights the steps involved in bridging the gap between OBD2 theory and hands-on application.

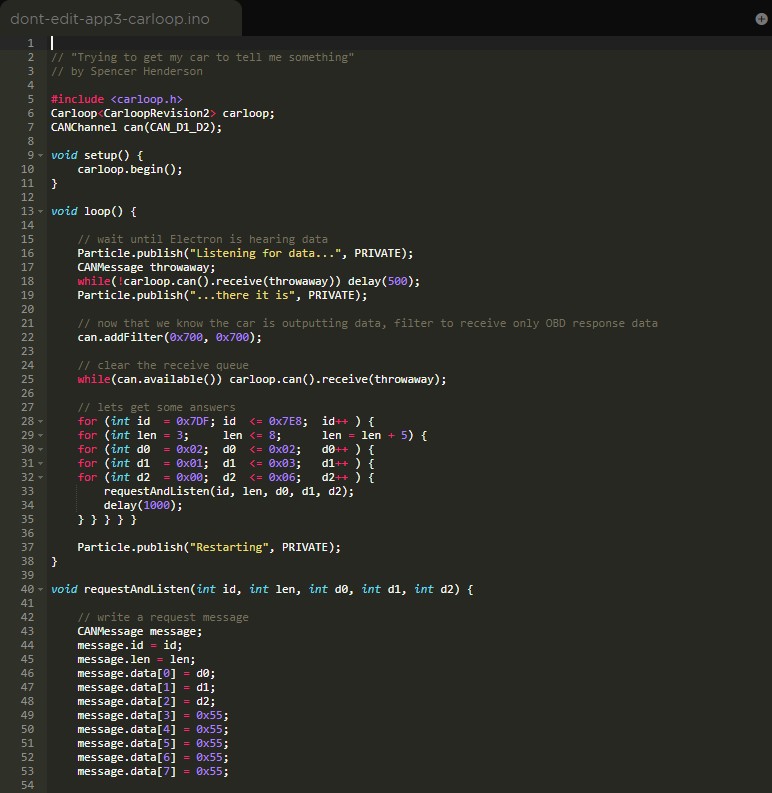

One of the key findings in this project involved using the Carloop library and ensuring correct initialization. The user outlined several crucial code modifications that enabled successful OBD2 data retrieval:

- Including the “carloop” library in the code.

- Adding

#include <carloop.h>to the program header. - Instantiating the Carloop object with

Carloop<carlooprevision2> carloop;. - Replacing

can.begin(500000);withcarloop.begin();. - Updating CAN receive and transmit commands to use

carloop.can().receive(message)andcarloop.can().transmit(message). - Adding data bytes to the message:

message.data[3] = 0x55; message.data[4] = 0x55; message.data[5] = 0x55; message.data[6] = 0x55; message.data[7] = 0x55;.

These steps underscore the importance of proper library integration and initialization when working with OBD2 interfaces like Carloop.

Code snippet showing successful OBD2 data retrieval using Carloop library, highlighting key code modifications for CAN bus communication and message handling in automotive diagnostics.

Code snippet showing successful OBD2 data retrieval using Carloop library, highlighting key code modifications for CAN bus communication and message handling in automotive diagnostics.

Understanding Message Length in OBD2 Communication

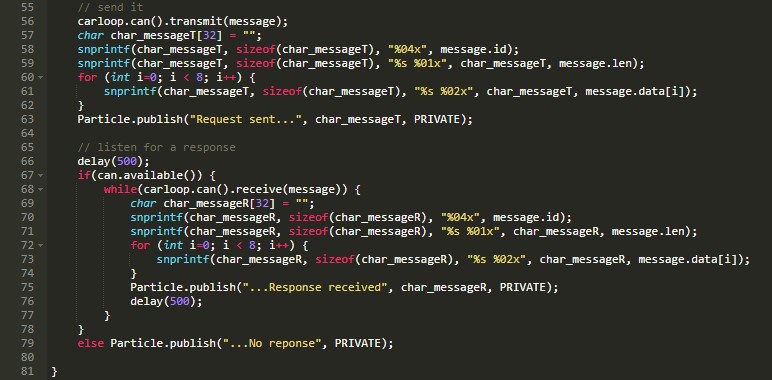

An intriguing observation from the Carloop project was the impact of message length on successful OBD2 communication. The user noted that messages with a length of 3 bytes (message.len=3;) did not elicit a response from the CAN bus, while extending the message length to 8 bytes (message.len=8;) resulted in successful data retrieval.

This finding suggests that the specific OBD2 implementation in the vehicle might require a certain message length for proper communication, particularly for transmit requests. While the exact reason for this behavior warrants further investigation, it emphasizes the nuances of OBD2 communication and the potential for vehicle-specific variations. It also highlights the importance of experimentation and iterative testing when working with OBD2 interfaces and custom diagnostic applications.

Code comparison illustrating the difference in CAN message length, where messages with len=3 failed to receive OBD responses while messages with len=8 successfully retrieved data from the vehicle's CAN bus.

Code comparison illustrating the difference in CAN message length, where messages with len=3 failed to receive OBD responses while messages with len=8 successfully retrieved data from the vehicle's CAN bus.

Conclusion: OBD2 – From Wikipedia to Real-World Applications

Understanding OBD2 starts with foundational knowledge, like that found on Wikipedia. However, the true power of OBD2 lies in its practical application. From diagnosing engine issues with a simple code reader to developing custom vehicle data logging systems with tools like Carloop, OBD2 offers a vast landscape for exploration. The experiences and code insights shared in projects like the Carloop example are invaluable for anyone looking to move beyond the theoretical and engage with the real-world potential of On-Board Diagnostics. As technology advances, OBD2 continues to be a critical gateway to understanding and interacting with the complex systems within our vehicles.