The electric vehicle revolution is accelerating, and understanding the technology powering these vehicles is becoming increasingly important. At cardiagnosticnearme.com, we delve deep into the mechanics of EVs to bring you insightful analysis. Following our exploration of the Nissan Leaf drive unit, we turned our attention to another intriguing specimen: the Smart Car Electric Drive unit from a Smart ForTwo.

This particular unit is somewhat rare, with limited publicly available information. It’s known to utilize a Bosch SMG 180/120 motor, boasting a 55KW output. This motor is noteworthy for its versatility, being an off-the-shelf component also found in vehicles like the Fiat 500e and even the front axle of the Porsche 918. This commonality makes it a prime candidate for integration into various electric vehicle projects.

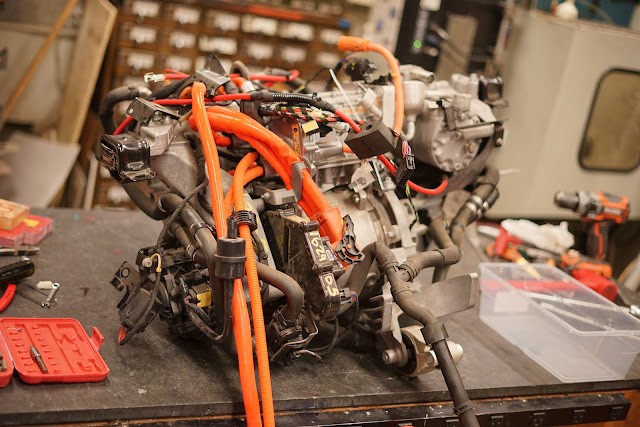

Smart ForTwo electric drive unit before disassembly

Smart ForTwo electric drive unit before disassembly

Our initial assessment revealed a somewhat clunky integration, which isn’t entirely surprising. The Smart ForTwo Electric Drive was likely produced in limited volumes, possibly as a compliance car to meet fleet mileage standards for Mercedes. Its market viability probably relied heavily on electric vehicle subsidies. For future reference, we documented the donor vehicle’s tag.

Donor vehicle tag of the Smart ForTwo electric drive unit

Donor vehicle tag of the Smart ForTwo electric drive unit

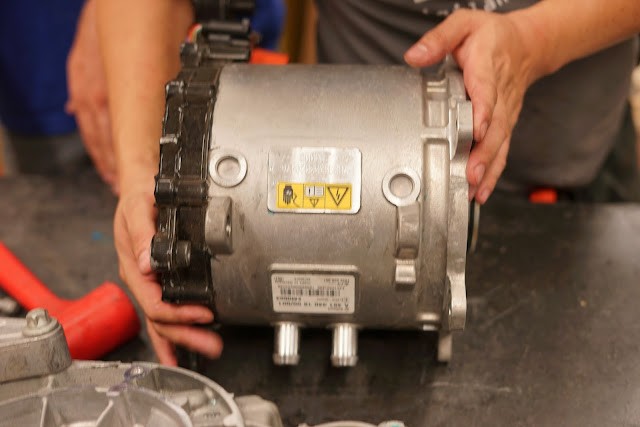

Before diving into the main components, we examined the air conditioning compressor. This unit is fully integrated, operating on DC power and communicating via CAN bus. Internally, it employs a scroll compressor design.

Smart ForTwo electric drive unit air conditioning compressor

Smart ForTwo electric drive unit air conditioning compressor

Further inspection of the compressor reveals an interior permanent magnet (PM) motor and a small inverter mounted on the back. While technologically interesting, its practicality for standalone use seems limited unless a 370VDC air conditioning system is specifically required.

Internal PM motor of the Smart ForTwo AC compressor

Internal PM motor of the Smart ForTwo AC compressor

Inverter attached to the back of the AC compressor motor

Inverter attached to the back of the AC compressor motor

Small inverter unit of the AC compressor

Small inverter unit of the AC compressor

Moving onto more substantial components, we examined the integrated charger. This is a 6.6KW unit manufactured by Lear.

Lear 6.6KW integrated charger unit from Smart ForTwo electric drive

Lear 6.6KW integrated charger unit from Smart ForTwo electric drive

Significant coolant draining was necessary before further disassembly could proceed, highlighting the integrated thermal management system within the smart car electric drive unit.

Coolant draining process of the Smart ForTwo electric drive unit

Coolant draining process of the Smart ForTwo electric drive unit

After draining the coolant, the charger was easily detached, revealing a neatly self-contained module.

Self-contained Lear charger unit detached from the electric drive unit

Self-contained Lear charger unit detached from the electric drive unit

Rear view of the detached Lear charger unit

Rear view of the detached Lear charger unit

While we didn’t delve deeper into the charger’s internal workings, it appears relatively straightforward to operate. It’s important to note that this charger handles AC-DC conversion but not battery balancing functions.

Next, we turned our attention to the inverter. Identifying a part number, we discovered it’s a Continental EFP 2-3 inverter, also marketed by Zytek.

Continental EFP 2-3 inverter unit of the Smart ForTwo electric drive

Continental EFP 2-3 inverter unit of the Smart ForTwo electric drive

Research indicates this inverter boasts a continuous current rating of 235A and a peak of 355A. Detaching the inverter from the assembly was achieved by removing a few bolts.

Continental inverter detached from the Smart ForTwo electric drive unit

Continental inverter detached from the Smart ForTwo electric drive unit

Compact size of the detached Continental inverter

Compact size of the detached Continental inverter

Its compact size is notable; the high-voltage cables likely outweigh the power electronics themselves. With the inverter removed, we separated the motor-gearbox unit from the rest of the smart car electric drive. The motor’s manageable size and round form factor are immediately appealing for potential conversions.

Smart ForTwo electric motor and gearbox assembly Smart ForTwo electric motor and gearbox assembly |

|---|

| Motor and gearbox unit separated from the drive assembly |

Separating the gearbox from the motor revealed a remarkably small traction motor.

Gearbox separated from the electric motor

Gearbox separated from the electric motor

Compact Bosch SMG 180/120 electric traction motor

Compact Bosch SMG 180/120 electric traction motor

The motor features a convenient mounting pattern, although suspending a 32kg motor from these tabs might not be ideal.

Mounting pattern of the Bosch SMG 180/120 motor

Mounting pattern of the Bosch SMG 180/120 motor

The gearbox, while smaller, shares a similar internal design to the Nissan Leaf’s gearbox.

Gearbox unit from the Smart ForTwo electric drive

Gearbox unit from the Smart ForTwo electric drive

Internally, the gearbox components exhibit a comparable structure.

Internal components of the Smart ForTwo gearbox unit

Internal components of the Smart ForTwo gearbox unit

Gearbox internal structure comparison

Gearbox internal structure comparison

Close up view of the gearbox gears

Close up view of the gearbox gears

Gearbox components and design details

Gearbox components and design details

Our attempt to further disassemble the inverter met with some challenges. The initial stages were promising, revealing pin-style cooling channels, likely designed to minimize pressure drop in the cooling system.

Inverter housing with pin-style cooling channels

Inverter housing with pin-style cooling channels

However, the high-voltage cable harness connection using large blade terminals was unexpected.

High voltage cable harness connection with blade terminals

High voltage cable harness connection with blade terminals

Ultimately, we decided against further disassembly of the inverter due to delicate ribbon cables connecting internal boards, making it unclear how to proceed without risking damage.

In conclusion, the smart car electric drive unit demonstrates significant potential for conversions, especially for smaller vehicles. Its somewhat rudimentary integration is advantageous, offering readily accessible mounting points. There’s also a reasonable possibility of obtaining datasheets for the inverter and motor from their respective manufacturers. However, the 55/80KW power output (80KW being Bosch’s peak motor rating) and 200Nm torque might be insufficient for full-size car conversions, potentially requiring dual units for adequate power.