The quest for efficient and compact electric drive units for vehicle conversions often leads us to explore less conventional sources. Following our exploration of the Nissan Leaf drive unit, we turned our attention to a somewhat enigmatic system: the Smart Fortwo Electric Drive unit. Information on this unit is scarce, making its acquisition and subsequent teardown particularly intriguing for those in the EV conversion and automotive repair fields. What we uncovered was a surprisingly accessible and well-engineered package centered around the Bosch SMG 180/120 motor, a component with a notable pedigree in the electric vehicle world.

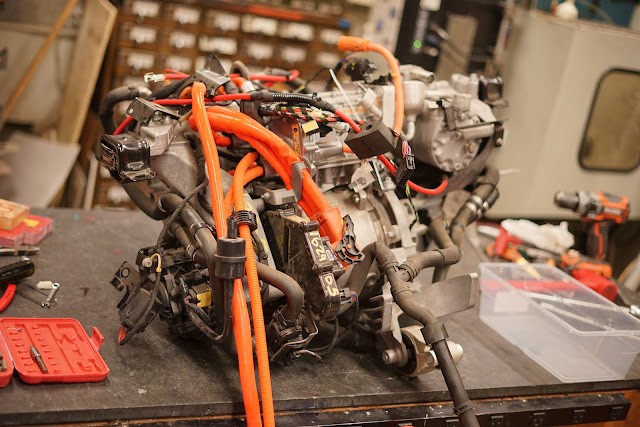

Smart Fortwo Electric Drive unit before disassembly, showcasing its compact design

Smart Fortwo Electric Drive unit before disassembly, showcasing its compact design

Initial impressions reveal a design philosophy perhaps driven more by compliance mandates than mass-market appeal. The Smart Fortwo Electric Drive, likely conceived to bolster Mercedes’ fleet average emissions and capitalize on EV subsidies, presents an integrated but somewhat constrained system. For documentation and future reference during our component analysis, we noted the donor vehicle’s identification tag.

Donor vehicle tag of the Smart Fortwo Electric Drive, essential for component identification and future research

Donor vehicle tag of the Smart Fortwo Electric Drive, essential for component identification and future research

Air Conditioning Compressor: A Compact and Integrated Unit

Our component exploration began with a slight detour – the air conditioning compressor. This component is a fully integrated unit, communicating via DC and CAN, indicating a sophisticated level of electronic control.

Integrated air conditioning compressor unit from the Smart Fortwo Electric Drive, highlighting its DC and CAN connectivity

Integrated air conditioning compressor unit from the Smart Fortwo Electric Drive, highlighting its DC and CAN connectivity

Internally, the compressor utilizes a scroll mechanism, driven by an interior permanent magnet (PM) motor. A small inverter is attached to the rear, suggesting a self-contained and efficient design. While potentially useful for specific applications requiring a 370VDC air conditioning system, its specialized nature led us to prioritize the core drive components.

Internal scroll compressor mechanism of the Smart Fortwo AC unit, showcasing its efficient design

Internal scroll compressor mechanism of the Smart Fortwo AC unit, showcasing its efficient design

Interior PM motor within the Smart Fortwo AC compressor, demonstrating compact integration

Interior PM motor within the Smart Fortwo AC compressor, demonstrating compact integration

Small inverter attached to the AC compressor unit, indicating a self-contained system for 370VDC operation

Small inverter attached to the AC compressor unit, indicating a self-contained system for 370VDC operation

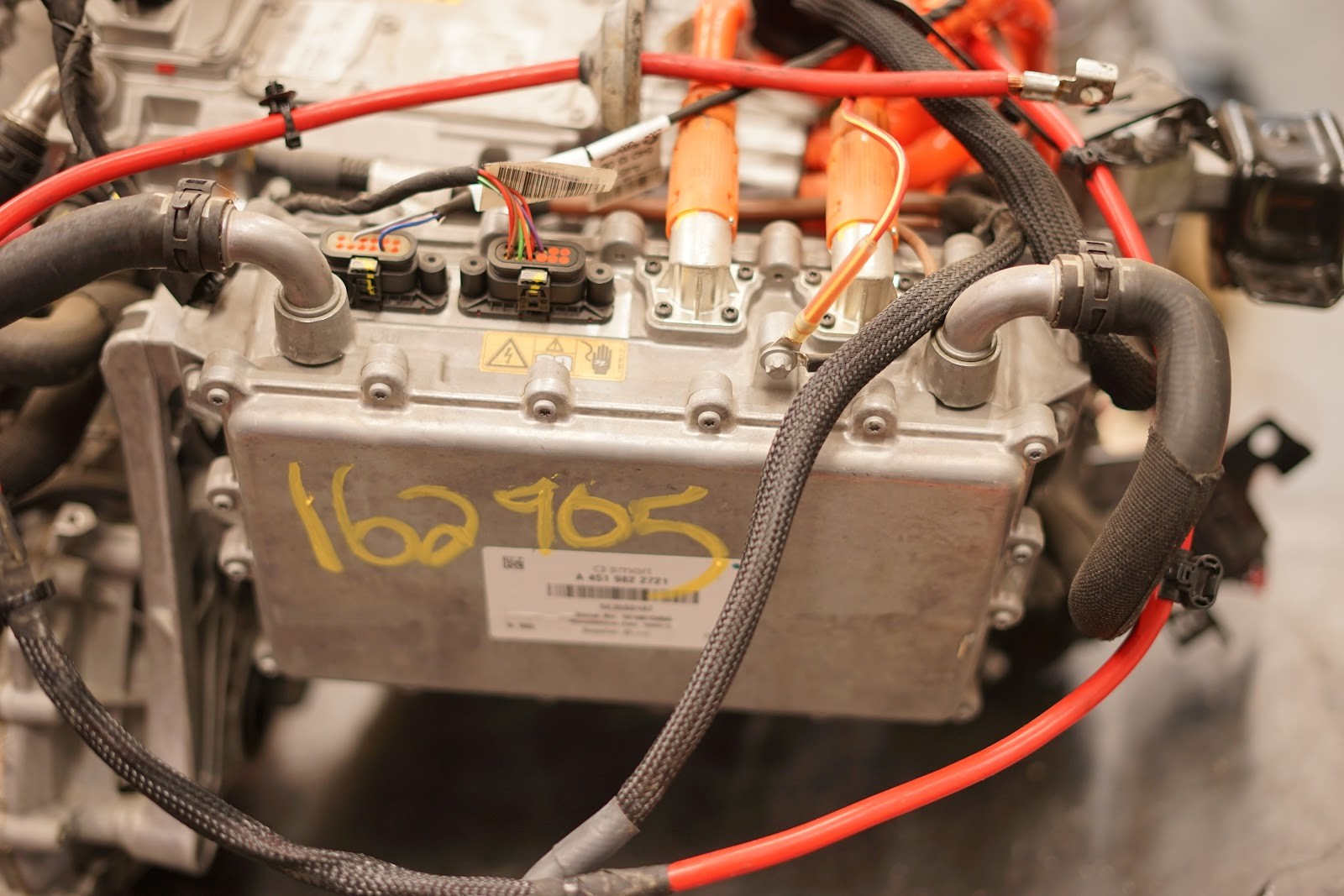

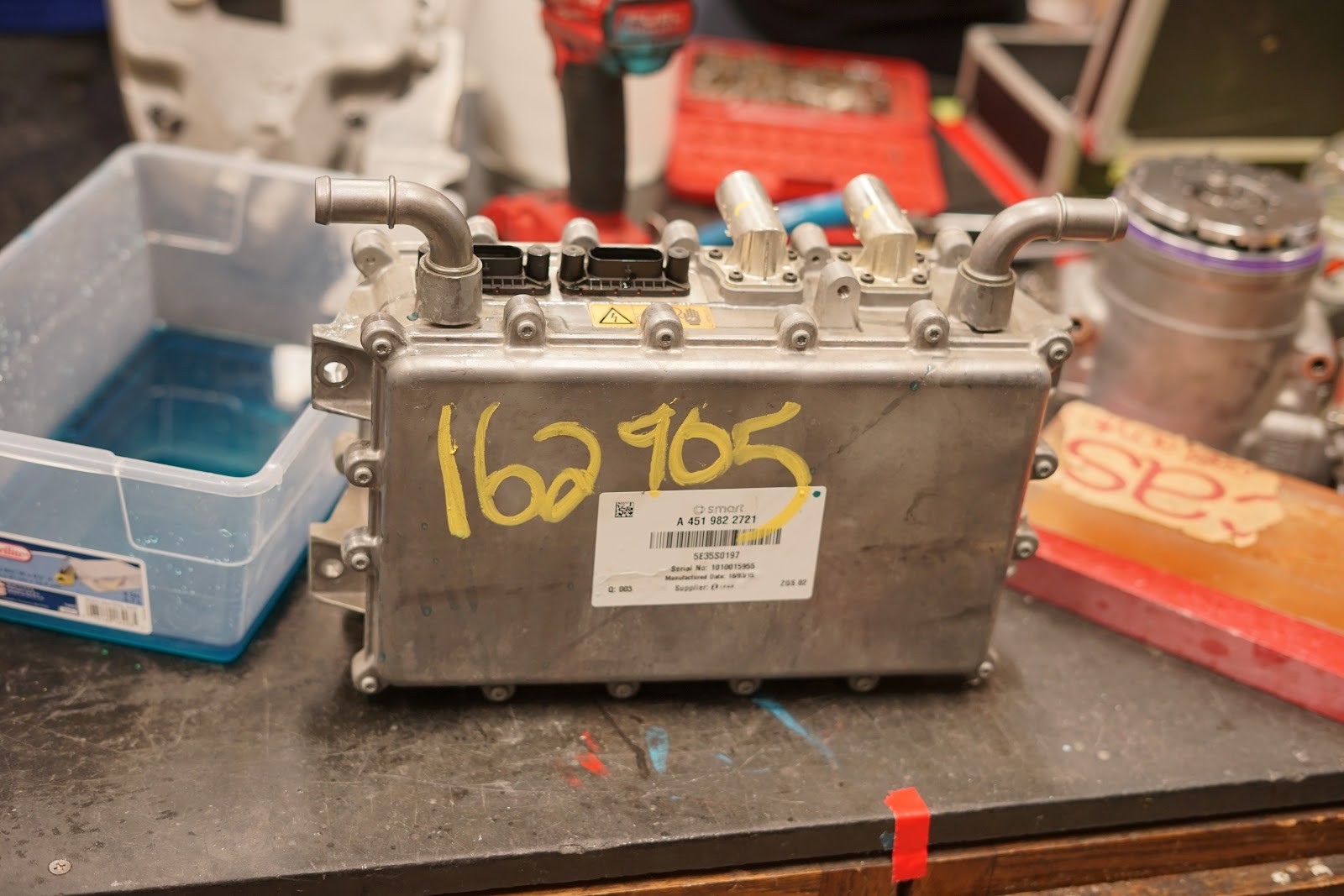

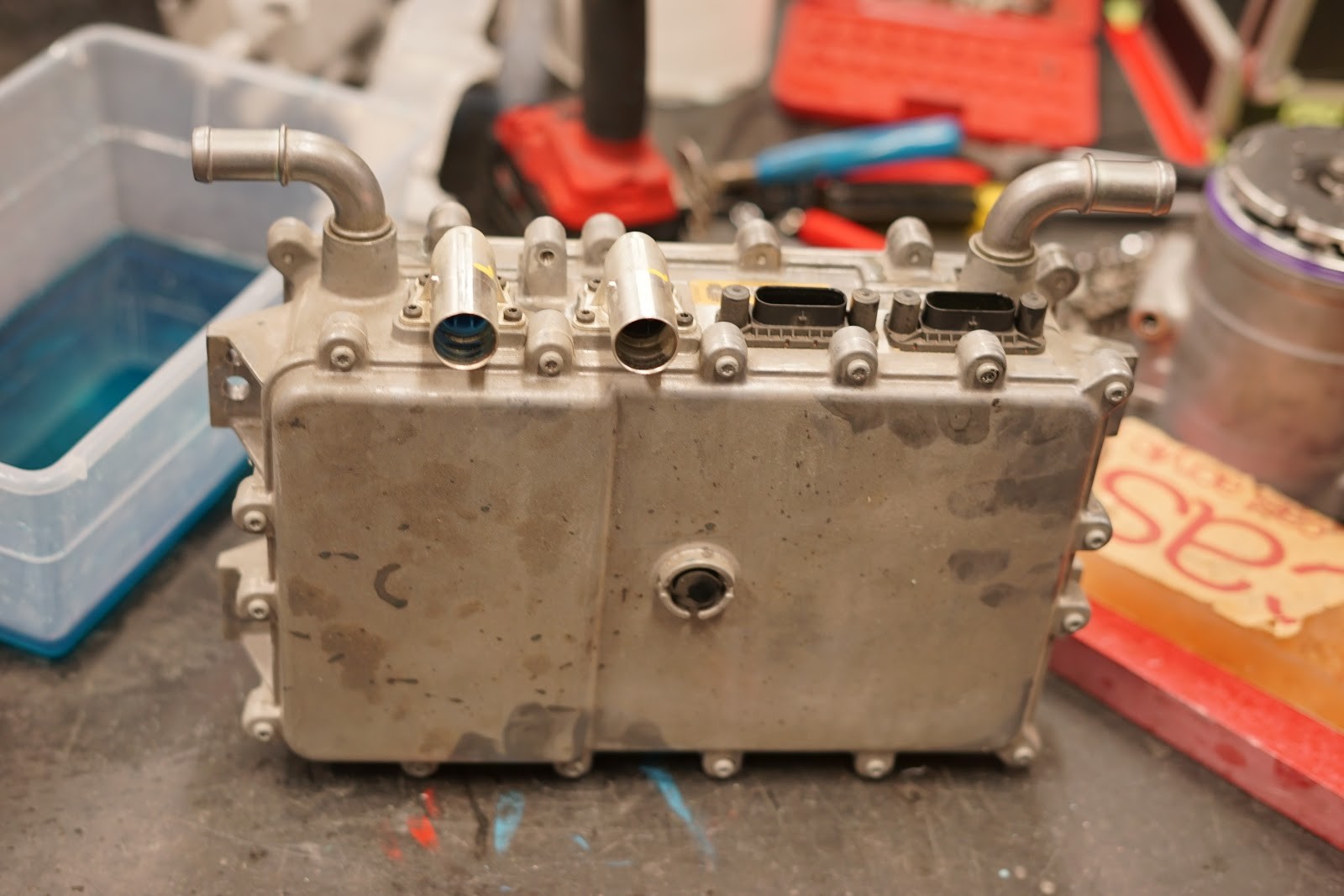

Onboard Charger: Lear 6.6KW Unit for AC-DC Conversion

Moving to more central components, we examined the integrated charger. This 6.6KW unit, manufactured by Lear, is responsible for AC-DC conversion during charging.

Lear 6.6KW onboard charger from the Smart Fortwo Electric Drive, a key component for battery charging

Lear 6.6KW onboard charger from the Smart Fortwo Electric Drive, a key component for battery charging

Accessing the charger required significant coolant drainage, a recurring theme throughout the disassembly process, highlighting the thermal management complexity within the unit.

Coolant draining process required to access the charger unit, showcasing the integrated thermal management system

Coolant draining process required to access the charger unit, showcasing the integrated thermal management system

Once detached, the charger revealed itself as a self-contained module, simplifying potential integration or replacement. It’s important to note that this charger is solely responsible for AC-DC conversion and does not handle battery balancing, a function typically managed by a separate battery management system (BMS).

Self-contained Lear 6.6KW charger unit after removal, simplifying potential integration in EV projects

Self-contained Lear 6.6KW charger unit after removal, simplifying potential integration in EV projects

Rear view of the detached charger unit, showing connection points and thermal management features

Rear view of the detached charger unit, showing connection points and thermal management features

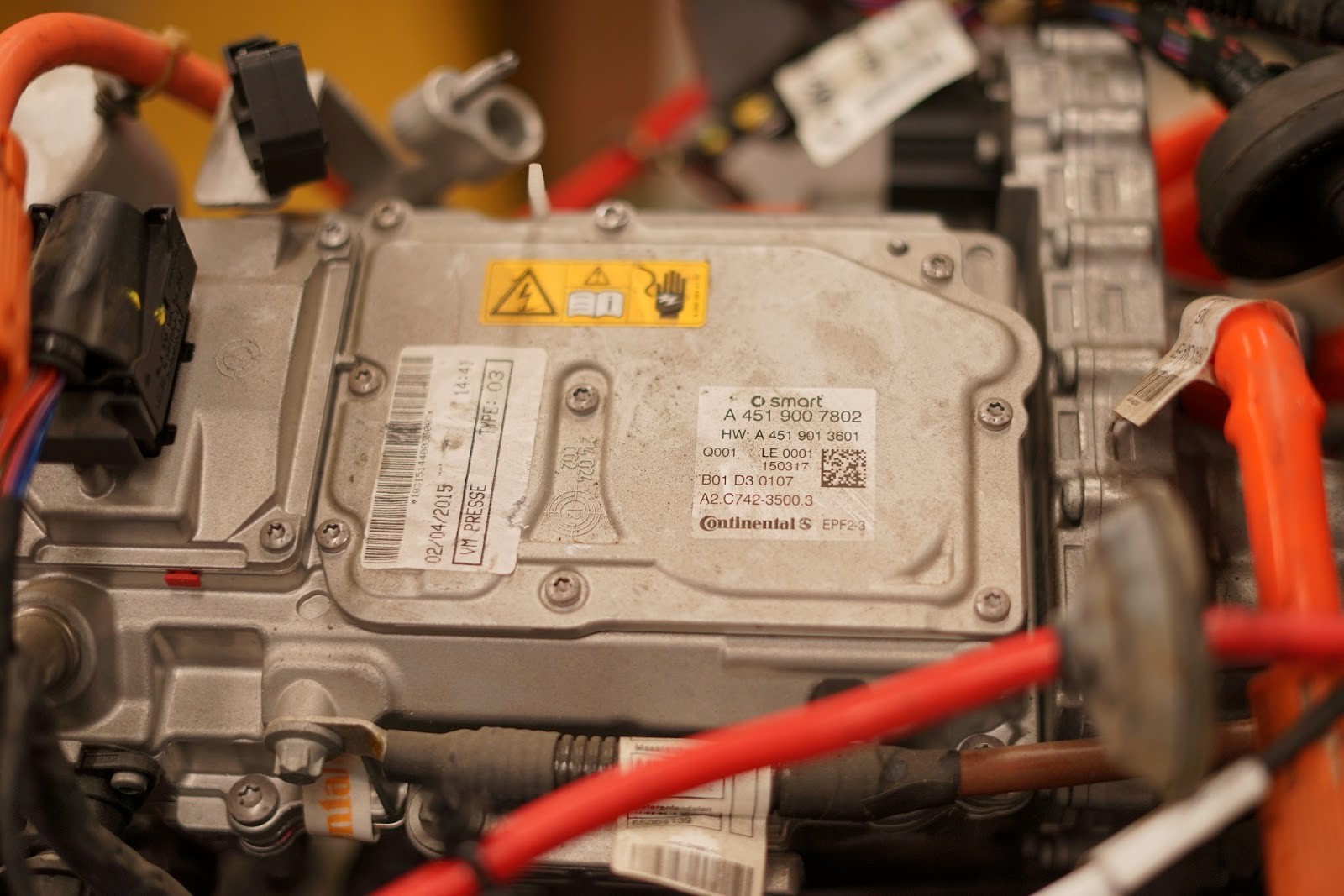

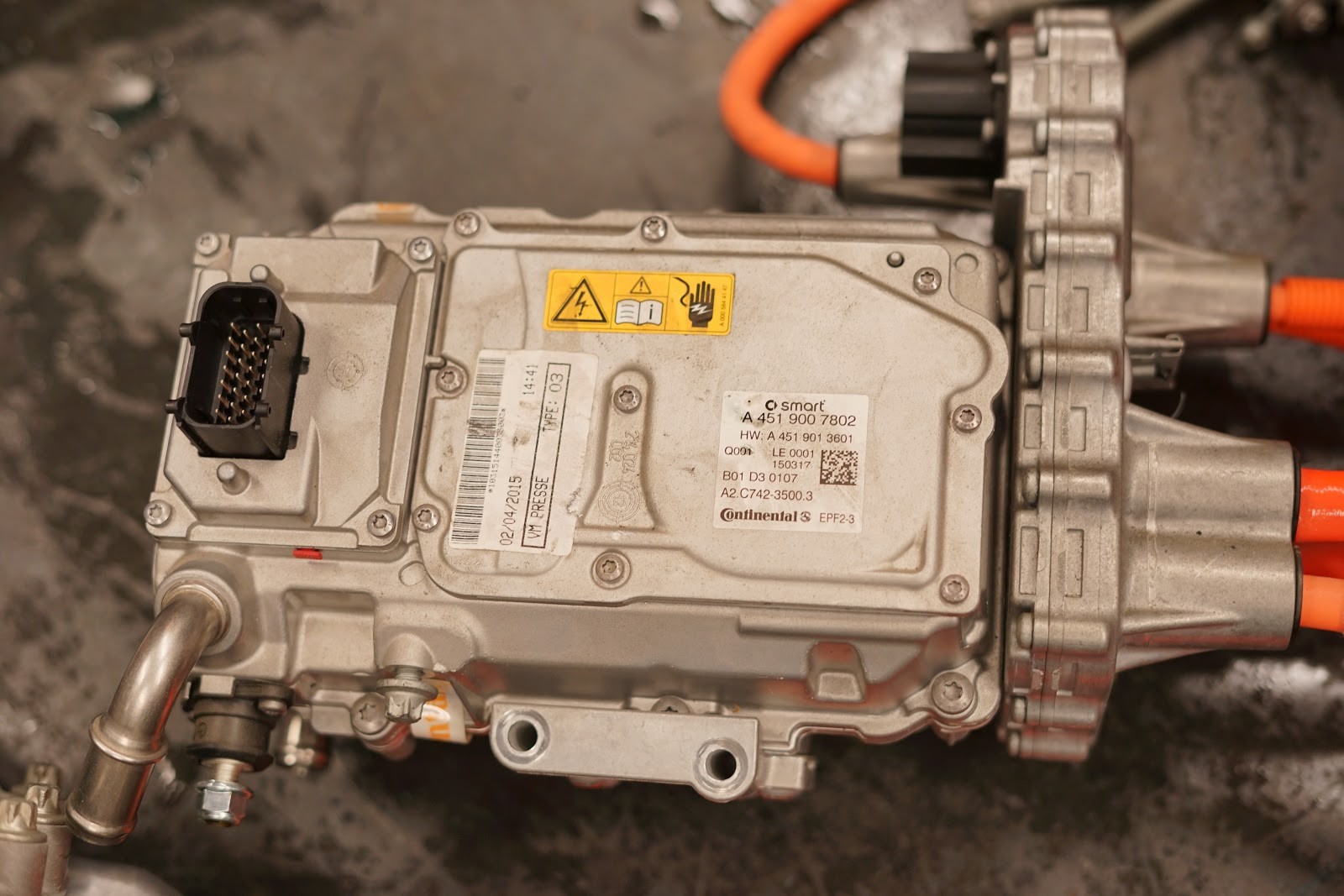

Inverter: Continental EFP 2-3 and Zytek Connection

Next, we turned our attention to the inverter, a critical component for converting DC battery power to AC for the motor. A visible part number led us to identify the inverter as a Continental EFP 2-3, also associated with Zytek Automotive.

Continental EFP 2-3 inverter unit from the Smart Fortwo Electric Drive, responsible for DC-AC power conversion

Continental EFP 2-3 inverter unit from the Smart Fortwo Electric Drive, responsible for DC-AC power conversion

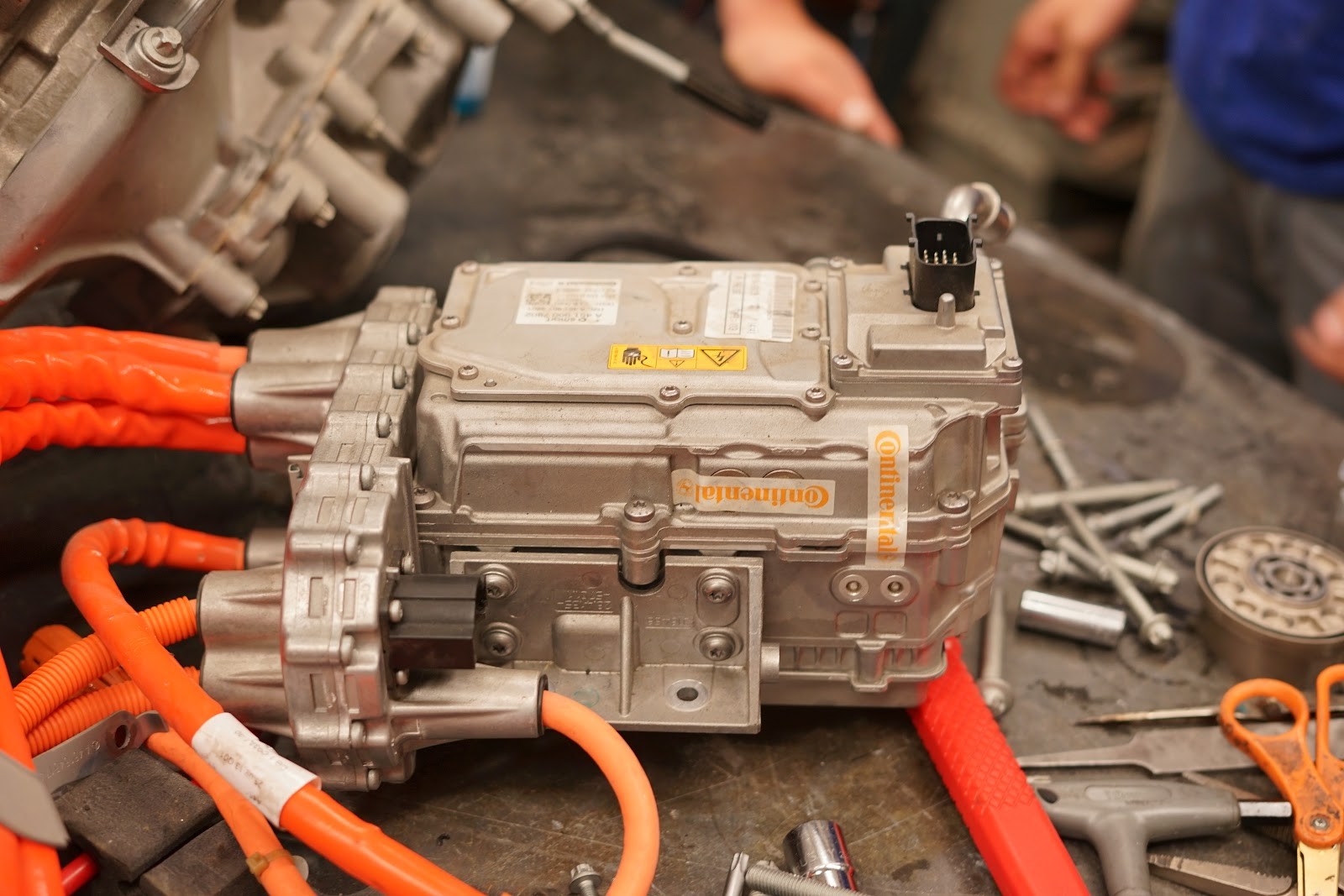

Research revealed this inverter to be capable of 235A continuous and 355A peak current. Physically detaching the inverter was straightforward, involving the removal of a few bolts.

Inverter unit detached from the main drive assembly, showcasing its compact and modular design

Inverter unit detached from the main drive assembly, showcasing its compact and modular design

Compact size of the detached inverter unit, highlighting its suitability for space-constrained EV conversions

Compact size of the detached inverter unit, highlighting its suitability for space-constrained EV conversions

The inverter’s diminutive size is notable, with the high voltage (HV) cables likely outweighing the power electronics themselves. With the inverter and other auxiliary components detached, we could finally focus on the core of the system – the motor and gearbox assembly.

Motor-gearbox unit separated from the rest of the drive system, ready for further disassembly Motor-gearbox unit separated from the rest of the drive system, ready for further disassembly |

|---|

| A closer look at the motor-gearbox assembly. |

Motor and Gearbox: Bosch SMG 180/120 – The Heart of the System

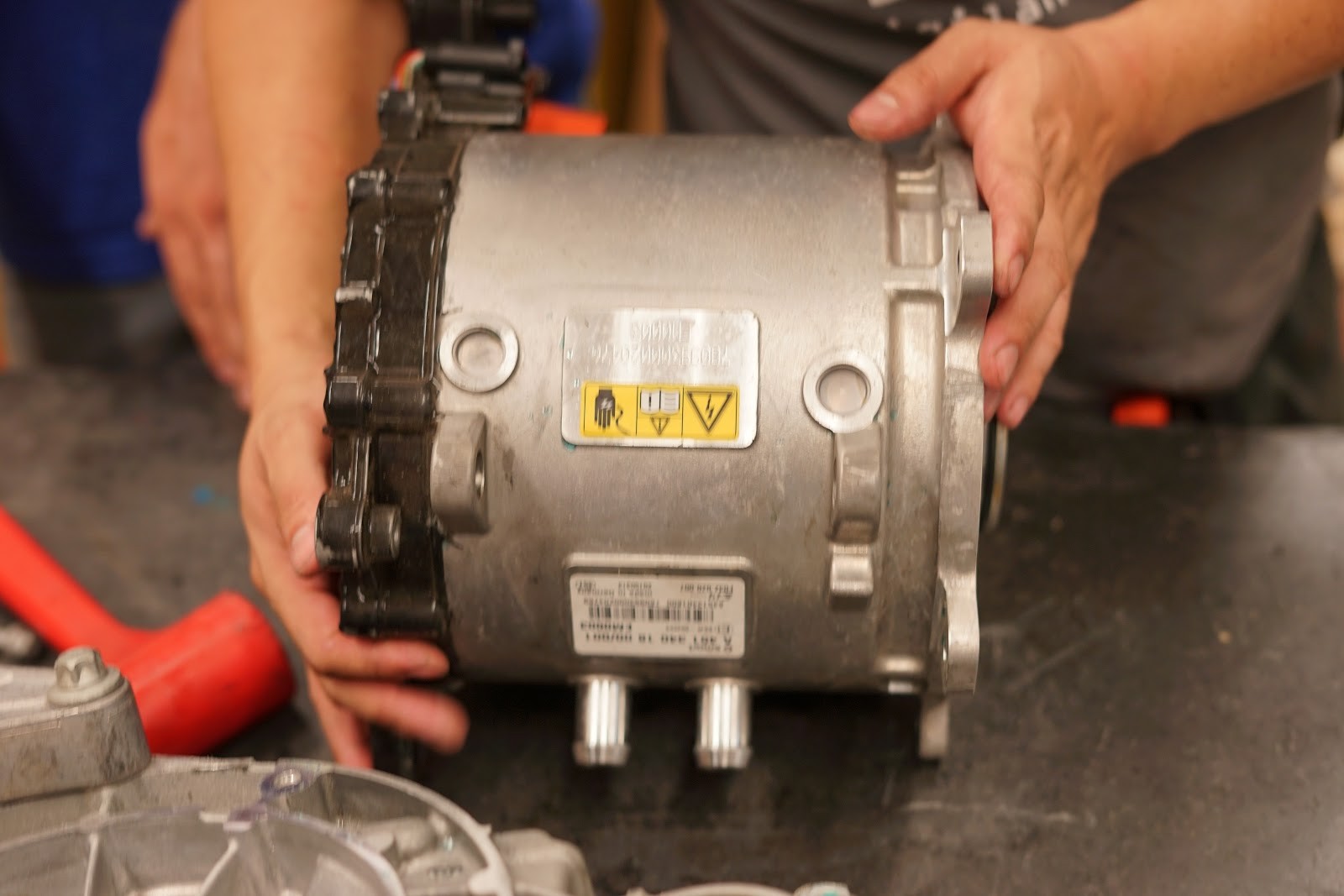

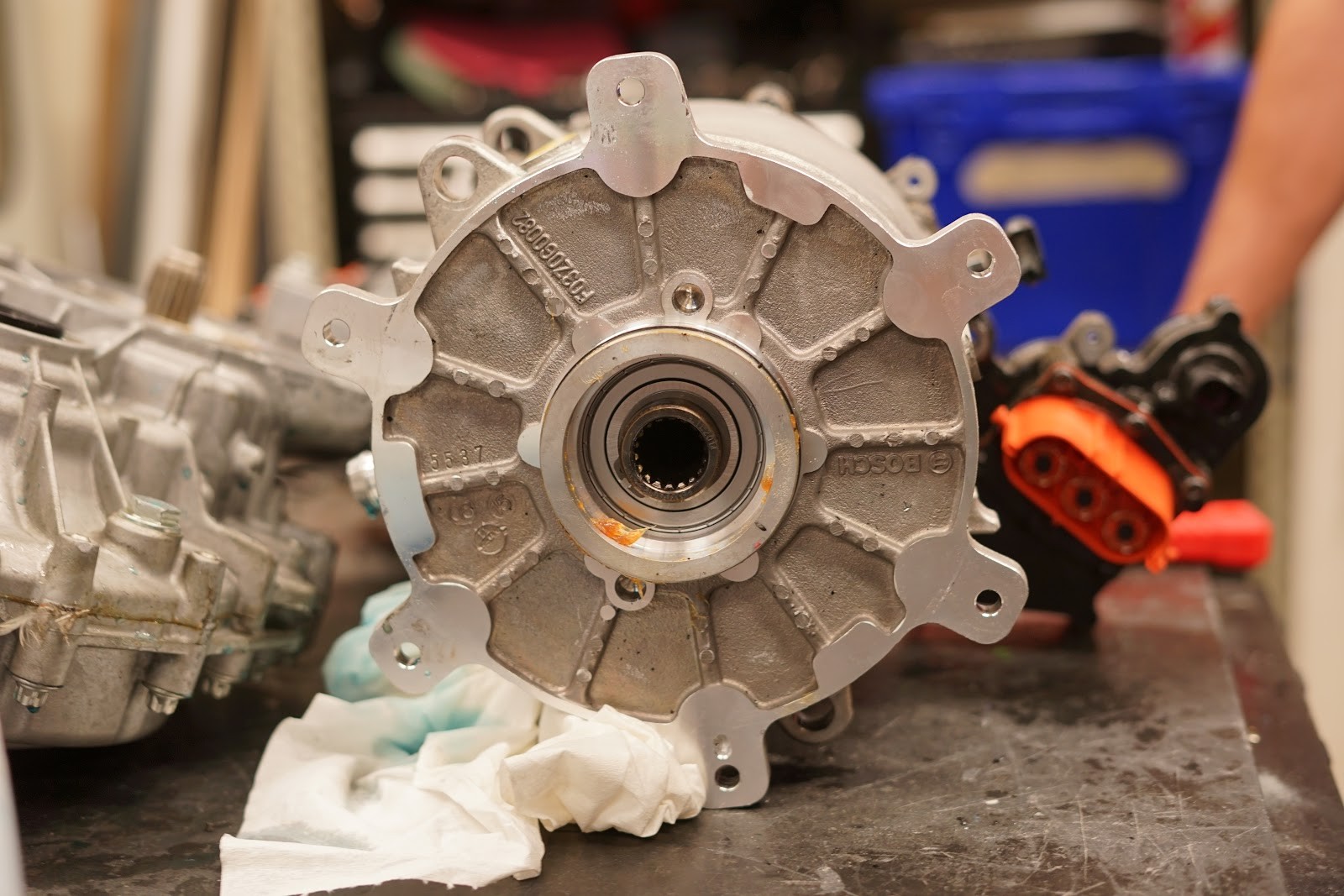

Separating the gearbox from the motor revealed the incredibly compact and “adorable” traction motor, as the original blog playfully notes.

Bosch SMG 180/120 motor separated from the gearbox, showcasing its remarkably small footprint

Bosch SMG 180/120 motor separated from the gearbox, showcasing its remarkably small footprint

The remarkably compact Bosch SMG 180/120 traction motor from the Smart Fortwo Electric Drive

The remarkably compact Bosch SMG 180/120 traction motor from the Smart Fortwo Electric Drive

The motor’s mounting pattern appears convenient for adaptation in various conversion projects. While the mounting tabs might raise concerns about long-term durability when supporting the 32kg motor, the overall design suggests ease of integration.

Convenient mounting pattern on the Bosch SMG 180/120 motor, simplifying integration into custom EV builds

Convenient mounting pattern on the Bosch SMG 180/120 motor, simplifying integration into custom EV builds

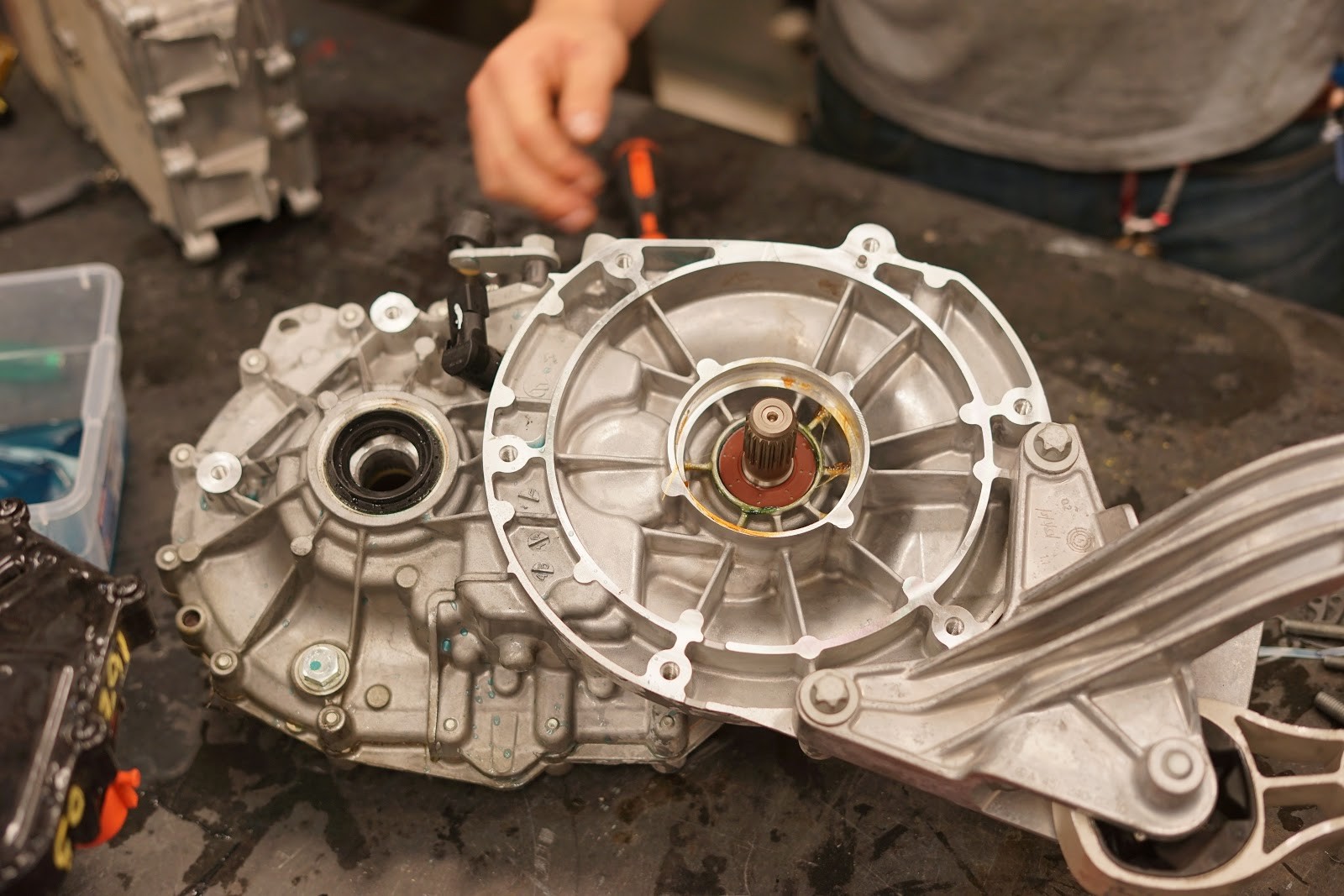

The gearbox, while smaller, exhibits a design remarkably similar to that of the Nissan Leaf, indicating a common approach to single-speed reduction in compact EVs.

Gearbox unit from the Smart Fortwo Electric Drive, showing design similarities to larger EV gearboxes like the Nissan Leaf

Gearbox unit from the Smart Fortwo Electric Drive, showing design similarities to larger EV gearboxes like the Nissan Leaf

Internal inspection confirms the gearbox’s design parallels with the Leaf unit, albeit in a more compact form factor, suitable for the Smart Fortwo’s smaller scale.

Internal components of the Smart Fortwo gearbox, revealing a compact but robust single-speed reduction system

Internal components of the Smart Fortwo gearbox, revealing a compact but robust single-speed reduction system

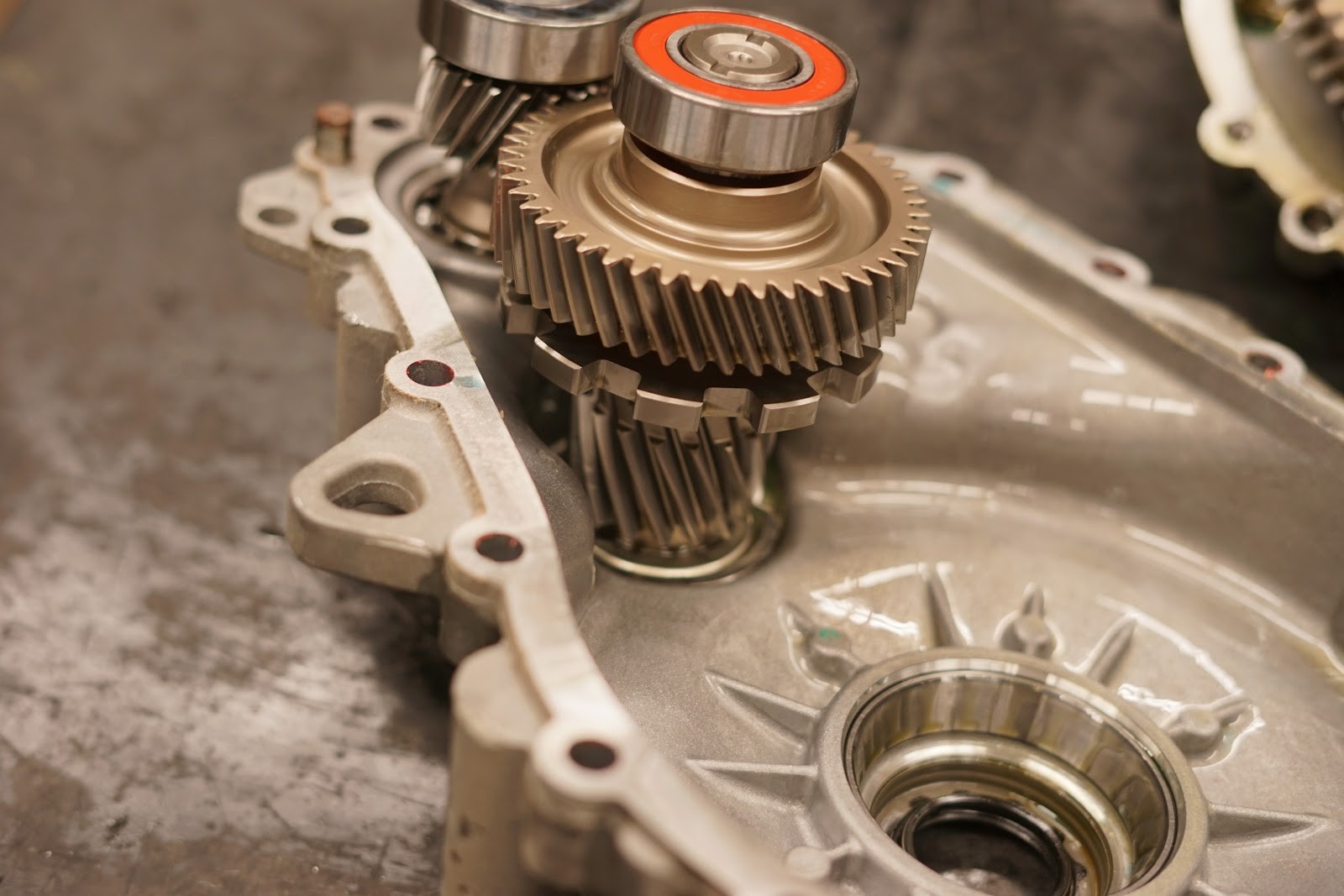

Further internal view of the gearbox, highlighting gear arrangement and lubrication pathways

Further internal view of the gearbox, highlighting gear arrangement and lubrication pathways

Close-up of gearbox components, showing machining quality and material selection

Close-up of gearbox components, showing machining quality and material selection

Another detailed view inside the gearbox, emphasizing the gear teeth and overall construction

Another detailed view inside the gearbox, emphasizing the gear teeth and overall construction

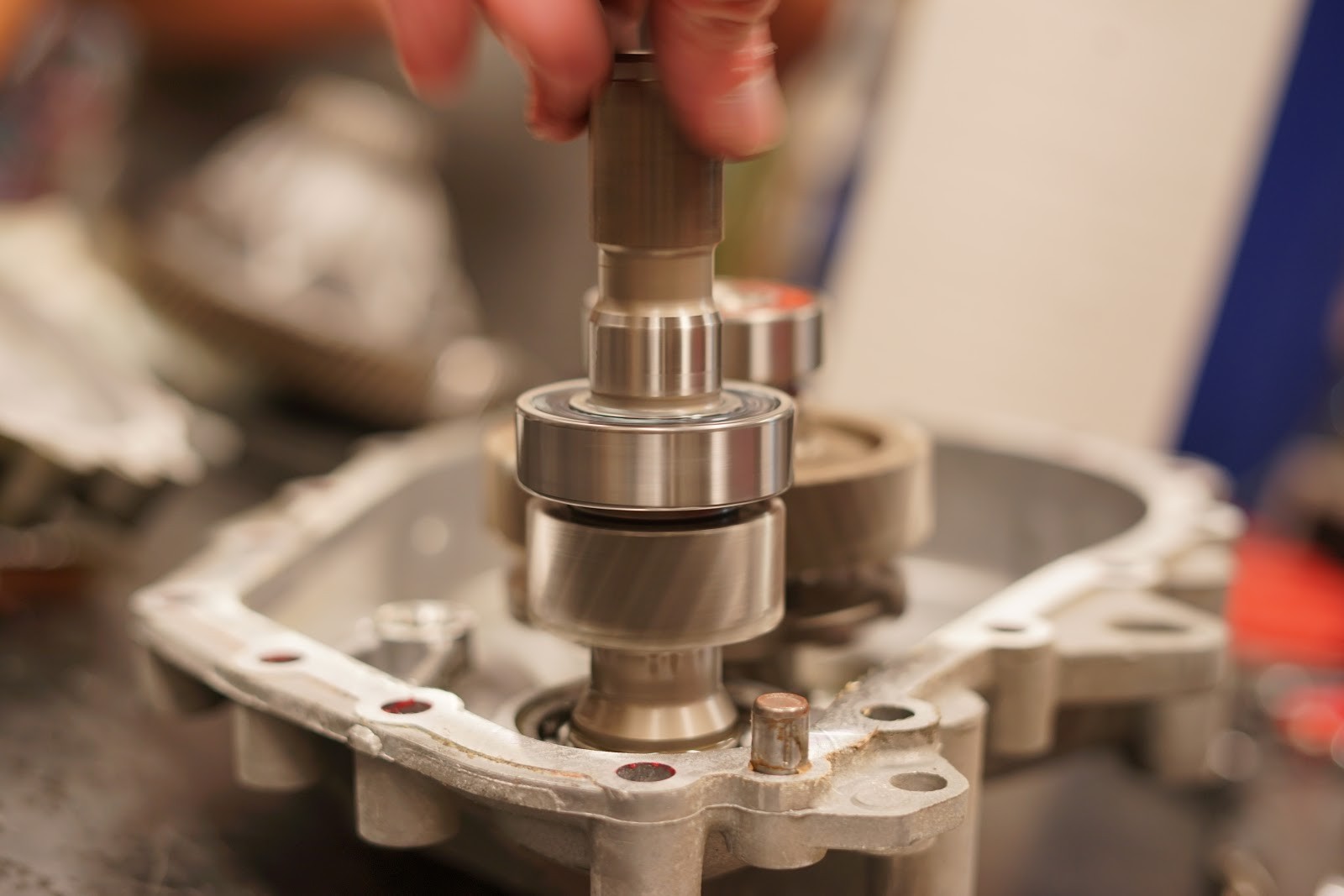

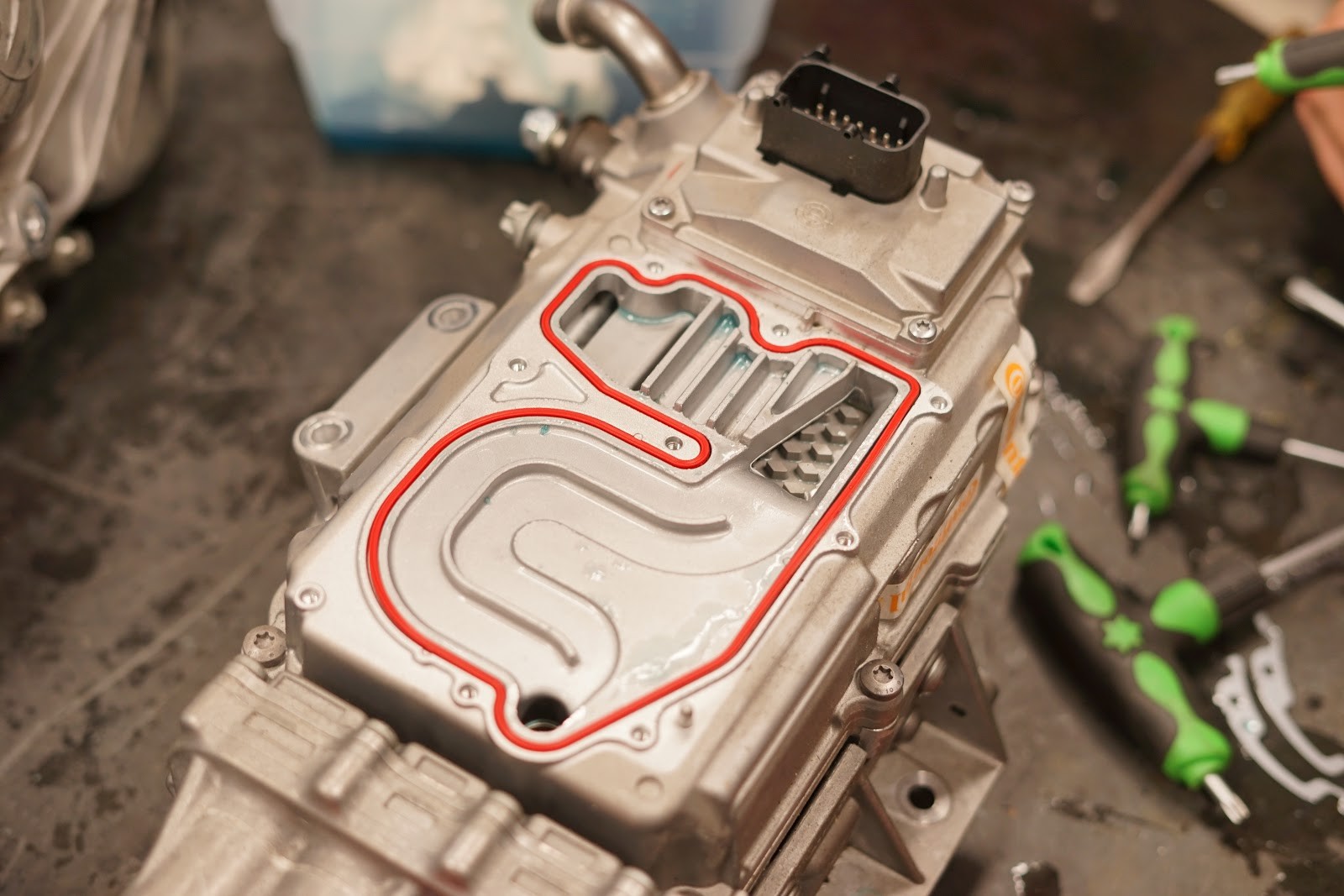

Our attempt to delve deeper into the inverter’s internals met with some resistance. While initial access was promising, revealing pin-style channels likely designed to minimize pressure drop within the cooling system, further disassembly became risky.

Initial access to the inverter internals, revealing cooling channels and component layout

Initial access to the inverter internals, revealing cooling channels and component layout

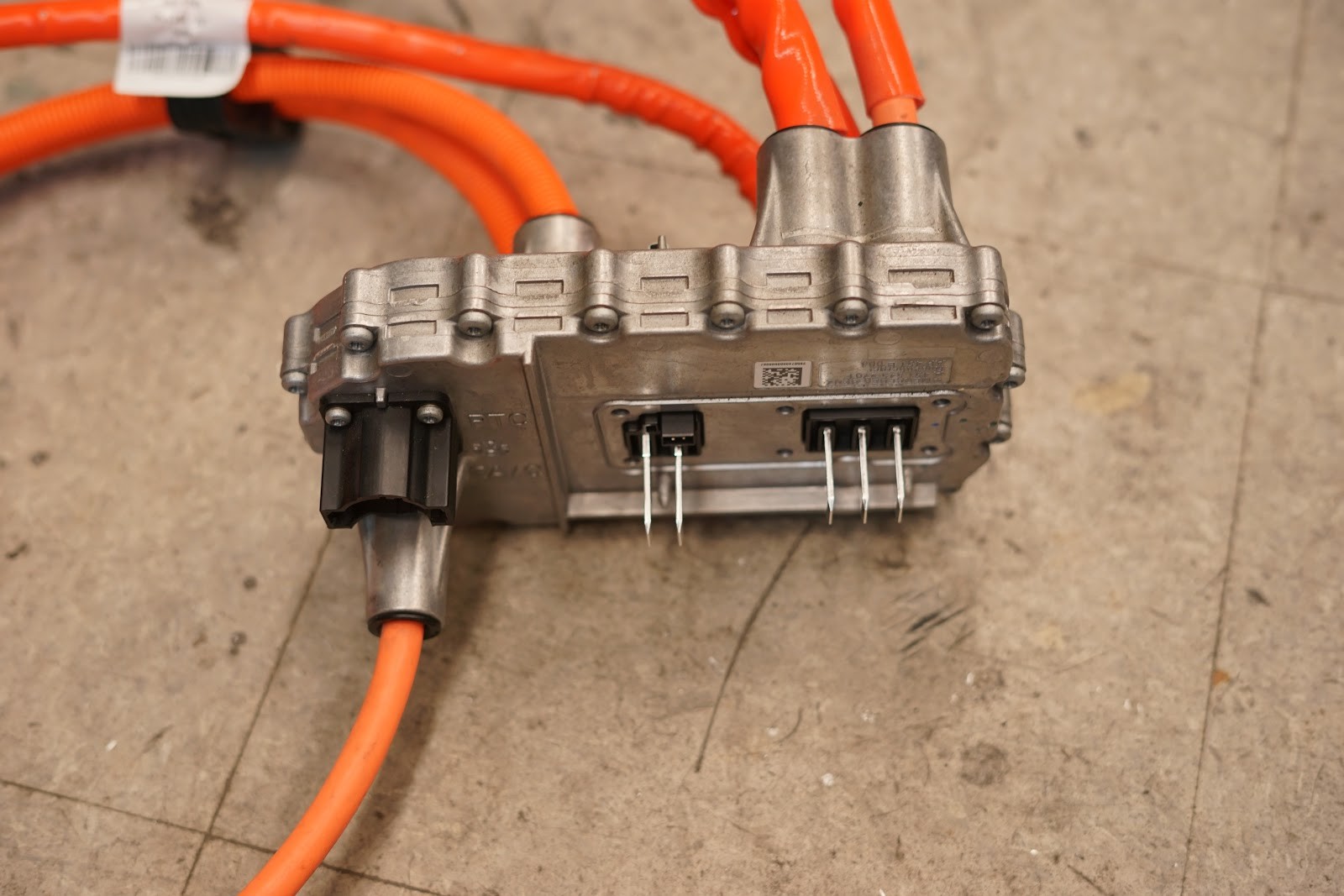

The high voltage cable harness connects via substantial blade terminals, indicating robust current carrying capability.

High voltage cable harness connection to the inverter using blade terminals, ensuring reliable high current flow

High voltage cable harness connection to the inverter using blade terminals, ensuring reliable high current flow

Unfortunately, the presence of delicate ribbon cables within the inverter housing, running to internal circuit boards, made further separation of the housing appear perilous, and we opted to halt disassembly at this stage to avoid damaging these components.

Conclusion: Promising Potential for Small EV Conversions

Overall, the Smart Fortwo Electric Drive unit presents a compelling option for those undertaking small electric vehicle conversions. Its somewhat “poor integration” from a mass-production standpoint ironically becomes an advantage for DIY converters. The components are relatively modular with sensible mounting points, increasing the chances of adapting them to custom chassis and vehicle designs.

The Bosch SMG 180/120 motor, with its off-the-shelf availability and reputable lineage (including applications in the Fiat 500e and Porsche 918 front axle), is a significant asset. While the 55KW continuous (80KW peak) power and 200Nm torque output may be insufficient for full-size car conversions in single-motor configuration, for smaller, lighter vehicles, or potentially in dual-motor setups, the Smart Fortwo drive unit holds considerable promise. The possibility of sourcing datasheets for the inverter and motor from their respective original equipment manufacturers (OEMs) further enhances its appeal for advanced EV conversion projects and automotive repair specialists seeking to understand and utilize these components.