If you’ve ever wondered about that mysterious port in your car, often used by mechanics to diagnose issues, you’re likely thinking of the OBD2 port. OBD2, or On-Board Diagnostics version 2, is a standardized system that has revolutionized vehicle diagnostics and repair. But When Did Obd2 Become Standard, and why is it so important?

In this comprehensive guide, we’ll delve into the history of OBD2, tracing its origins, the key milestones in its standardization, and its evolution into the system we know today. Understanding the timeline of OBD2 adoption is crucial for anyone in the automotive industry, from mechanics and technicians to car enthusiasts and vehicle owners.

Understanding OBD2: The malfunction indicator light, often called the check engine light, is a key component of the On-Board Diagnostics system, signaling potential vehicle issues.

The Precursor to OBD2: OBD-I and the Need for Emission Control

To truly understand when OBD2 became standard, we need to rewind a bit and look at its predecessor, OBD-I. In the late 1960s and 1970s, concerns about air pollution began to rise, particularly in California. This led the California Air Resources Board (CARB) to mandate the inclusion of diagnostic systems in vehicles to monitor emission control components.

This initial effort resulted in On-Board Diagnostics (OBD-I). While OBD-I was a step in the right direction, it lacked standardization. Each manufacturer implemented their own diagnostic systems, using different connectors, communication protocols, and diagnostic trouble codes (DTCs). This lack of uniformity made it challenging for mechanics and technicians to diagnose and repair vehicles from different manufacturers efficiently.

The Dawn of Standardization: OBD2’s Genesis and Timeline

The limitations of OBD-I highlighted the clear need for a standardized diagnostic system. This realization paved the way for the development and eventual standardization of OBD2. The push for OBD2 was largely driven by the need for more effective emission control and the desire to simplify vehicle diagnostics across the automotive industry.

Here’s a timeline outlining the key milestones in when OBD2 became standard:

-

Early 1990s – California Leads the Way: The California Air Resources Board (CARB), continuing its pioneering role in emission control, began pushing for enhanced on-board diagnostic requirements. This was a crucial catalyst for the development of OBD2. By 1991, CARB mandated OBD systems in all new vehicles sold in California for enhanced emission monitoring.

-

1994 – OBD-II Standard Emerges (SAE J1979): The Society of Automotive Engineers (SAE) played a pivotal role in defining the OBD2 standard. SAE standard J1979 outlined the diagnostic test modes, standardized DTCs, and communication protocols, aiming for uniformity across manufacturers. This standardization effort was critical in setting the stage for OBD2’s widespread adoption.

-

1996 – OBD2 Becomes Mandatory in the USA for Cars and Light Trucks: 1996 marks the pivotal year when OBD2 became standard in the United States for all new passenger cars and light trucks. This mandate by the Environmental Protection Agency (EPA) meant that all vehicles sold in the US had to be OBD2 compliant. This was a major step towards cleaner emissions and simplified diagnostics.

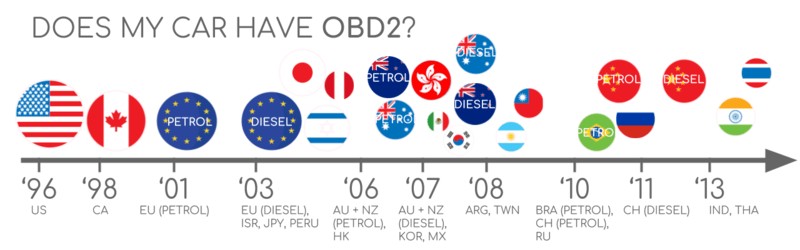

Does My Car Have OBD2?

Does My Car Have OBD2?

-

2001 – OBD2 Required for Gasoline Cars in the European Union (EOBD): The European Union followed suit, making OBD2 mandatory for all new gasoline-powered passenger cars sold within the EU starting in 2001. In Europe, the standard is often referred to as EOBD (European On-Board Diagnostics), which is largely equivalent to OBD2.

-

2003 – EOBD Mandated for Diesel Cars in the EU: Extending the emission control net further, the EU mandated EOBD for all new diesel passenger cars from 2003. This ensured that both gasoline and diesel vehicles in the EU adhered to the standardized diagnostic protocols.

-

2005 – OBD2 for Medium Duty Vehicles in the USA: The scope of OBD2 standardization in the US expanded to include medium-duty vehicles starting in 2005. This broadened the impact of OBD2 to a wider range of commercial vehicles.

-

2008 – CAN Bus as the Standard OBD2 Protocol in the USA: A significant technical update occurred in 2008 when the US mandated the Controller Area Network (CAN bus) protocol (ISO 15765-4) as the required communication protocol for OBD2 in all vehicles sold in the US. CAN bus offered higher speed and reliability compared to earlier protocols, enhancing diagnostic capabilities.

-

2010 – OBD2 for Heavy Duty Vehicles in the USA: Finally, in 2010, OBD2 standardization reached heavy-duty vehicles in the United States, completing the phased rollout across all major vehicle categories.

OBD2 History and Emission Control: OBD2’s development is intrinsically linked to emission control regulations, aiming to reduce vehicle pollutants and improve air quality.

Why Standardize OBD2? The Benefits of a Universal System

The push to standardize OBD2 was not arbitrary. It was driven by a multitude of compelling reasons, all aimed at improving the automotive landscape for both consumers and industry professionals:

-

Enhanced Emission Control: The primary driver was to enforce stricter emission standards. OBD2 systems continuously monitor key emission-related components and systems, ensuring vehicles operate within regulatory limits. By standardizing OBD2, regulatory bodies could more effectively ensure compliance across all manufacturers.

-

Simplified Diagnostics and Repair: Before OBD2, diagnosing vehicle problems was often a complex and manufacturer-specific process. OBD2 standardization meant that mechanics could use a single scan tool to communicate with virtually any vehicle, retrieve diagnostic trouble codes (DTCs), and access real-time data. This significantly streamlined the diagnostic process, saving time and costs.

-

Increased Transparency for Consumers: OBD2 provides vehicle owners with greater insight into their car’s health. The standardized DTCs and readily available scan tools empower consumers to understand potential issues and communicate more effectively with mechanics.

-

Facilitated Aftermarket Innovation: The OBD2 standard opened doors for innovation in the automotive aftermarket. Third-party companies could develop scan tools, diagnostic software, and performance monitoring devices, creating a competitive market that benefited both consumers and the industry.

-

Global Harmonization: While the initial mandates were regional (California, USA, EU), the OBD2 standard has been widely adopted globally. This harmonization simplifies vehicle manufacturing, export, and repair across different markets.

OBD2 History Timeline: A visual representation of the key dates and milestones in the standardization and implementation of OBD2 systems worldwide.

OBD2 Standards and Protocols: The Technical Backbone

The standardization of OBD2 wasn’t just about the connector; it encompassed a comprehensive set of standards and protocols that defined how diagnostic information is communicated. Key aspects of OBD2 standardization include:

-

OBD2 Connector (SAE J1962 / ISO 15031-3): The 16-pin Diagnostic Link Connector (DLC) is a hallmark of OBD2. Its standardized physical interface ensures that scan tools can connect to any OBD2-compliant vehicle.

-

Communication Protocols (ISO 15765-4, ISO 14230-4, ISO 9141-2, SAE J1850 VPW, SAE J1850 PWM): While CAN bus (ISO 15765-4) is the dominant protocol today, the OBD2 standard initially encompassed five communication protocols. This accommodated the transition from older protocols to the more advanced CAN bus.

-

Diagnostic Services (SAE J1979 / ISO 15031-5): Standardized diagnostic services (or modes) define the types of diagnostic requests and responses. These include services for retrieving current data, freeze frame data, diagnostic trouble codes, and more.

-

Parameter IDs (PIDs): OBD2 standardized hundreds of Parameter IDs (PIDs) that represent real-time vehicle data, such as engine speed, coolant temperature, and oxygen sensor readings. This standardization ensures that the same PID refers to the same parameter across different vehicles.

-

Diagnostic Trouble Codes (DTCs) (SAE J2012 / ISO 15031-6): A standardized library of Diagnostic Trouble Codes (DTCs) was established, providing consistent fault codes across manufacturers. This allows mechanics to quickly identify the nature of a problem using a standardized code format.

OBD2 and CAN Bus Standards: This OSI model illustrates how OBD2 protocols operate on top of the CAN bus physical and data link layers, highlighting the layered architecture of vehicle communication.

The OBD2 Connector: Your Gateway to Vehicle Data

The standardized 16-pin OBD2 connector, specified in SAE J1962 and ISO 15031-3, is the physical interface that makes OBD2 accessible. Typically located within reach of the driver’s seat, this connector provides access to the vehicle’s diagnostic network.

OBD2 Connector Pinout: A detailed view of the Type A OBD2 connector pin assignments, illustrating the standardized interface for accessing vehicle diagnostic data.

Key features of the OBD2 connector include:

-

16 Pins: The connector has 16 pins, each assigned for specific purposes, including power, ground, communication lines (like CAN bus), and manufacturer-specific pins.

-

Standardized Location: While the exact location may vary slightly by vehicle model, OBD2 connectors are generally found under the dashboard on the driver’s side, making them easily accessible for diagnostic tools.

-

Power Supply: Pin 16 provides battery power, allowing scan tools to operate even when the vehicle’s ignition is off.

-

Protocol Specific Pins: Depending on the communication protocol used by the vehicle, specific pins are used for data transmission and reception. For CAN bus, pins 6 (CAN-High) and 14 (CAN-Low) are crucial.

OBD2 and CAN Bus: A Powerful Partnership

Since 2008 in the US, CAN bus (ISO 15765-4) has become the mandatory lower-layer protocol for OBD2. CAN bus is a robust and efficient communication network that allows various electronic control units (ECUs) within a vehicle to communicate with each other. Its adoption as the standard for OBD2 has brought several advantages:

-

High-Speed Communication: CAN bus offers significantly higher data rates compared to older protocols, enabling faster diagnostics and real-time data acquisition.

-

Robustness and Reliability: CAN bus is designed to operate reliably in the harsh automotive environment, resistant to noise and interference.

-

Efficient Data Handling: CAN bus is optimized for message-based communication, making it well-suited for transmitting diagnostic data and control signals within a vehicle.

-

Widespread Adoption: CAN bus is the dominant in-vehicle network in modern vehicles, making it a natural choice for the standardized OBD2 protocol.

OBD2 vs. CAN Bus: A comparison highlighting that OBD2 is a higher-layer diagnostic protocol that often utilizes CAN bus as its underlying communication network.

The Future of OBD2: Evolution and Adaptation

While OBD2 has been a cornerstone of vehicle diagnostics for decades, the automotive industry continues to evolve. Several trends are shaping the future of OBD2 and on-board diagnostics:

-

OBD3 and Remote Diagnostics: The concept of OBD3 envisions taking diagnostics a step further by incorporating telematics and remote reporting capabilities. This could enable vehicles to automatically report emission-related issues to regulatory authorities, streamlining compliance and potentially facilitating proactive maintenance.

-

WWH-OBD (World-Wide Harmonized OBD): Efforts are underway to further harmonize OBD standards globally through initiatives like WWH-OBD. This aims to create a single, unified OBD standard that can be used worldwide, simplifying vehicle design and compliance.

-

OBD on UDS (OBDonUDS): Modern diagnostic protocols like UDS (Unified Diagnostic Services – ISO 14229) are being integrated with OBD. OBDonUDS leverages the more advanced features of UDS while maintaining compatibility with OBD diagnostic services.

-

Challenges with Electric Vehicles (EVs): The rise of electric vehicles presents new challenges for OBD2. Traditional OBD2 was primarily designed for emission control in internal combustion engine vehicles. EVs have different emission profiles and powertrain systems, requiring adaptations to diagnostic strategies. Currently, many EVs do not fully support standard OBD2 protocols, often relying on OEM-specific diagnostic methods.

OBD2 Future Trends: Illustrating the potential evolution of OBD2 towards OBD3, incorporating remote diagnostics, cloud connectivity, and IoT technologies for enhanced vehicle monitoring.

Conclusion: OBD2 – A Standard that Transformed Automotive Diagnostics

When did OBD2 become standard? The answer lies in a progressive timeline, with 1996 marking the critical year of mandatory OBD2 adoption in the USA for cars and light trucks. This milestone, preceded by California’s pioneering efforts and SAE standardization, fundamentally changed automotive diagnostics.

OBD2 standardization has yielded immense benefits, from cleaner emissions and simplified repairs to increased transparency for vehicle owners and innovation in the aftermarket. As the automotive industry advances, OBD2 continues to adapt, paving the way for even more sophisticated diagnostic systems in the future. Understanding the history and evolution of OBD2 is essential for navigating the complexities of modern vehicle technology.

Whether you are a seasoned mechanic, a curious car owner, or an automotive engineer, appreciating the significance of when OBD2 became standard provides valuable context for the diagnostic landscape we operate within today.